-

Posts

5,524 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Posts posted by Gixer1460

-

-

On 9/16/2018 at 4:29 PM, Dezza said:

If that doesn't work, unscrew the rubbers from the head and remove with the carbs and repeat the process

Virtually impossible to get to all the screws with the carbs in place and / or at all if in frame .......... yes - I have tried! Gentle heating generally works though and they can take some serious heat ie over 100 deg C

-

35 minutes ago, Duckndive said:

OEM every time....

x2 - streetbike through funnybike ALL use OEM! Don't know about roundy - roundy .... they never seem to stay vertical long enough to worry about clutch slippage LOL!

-

If you haven't got the 40mm inlet rubbers - your going to need them whichever type of carb so can't see how the Keihins will be a cheaper solution?

Yes I have used EFI - you do not NEED a cam sensor for EFI only if you want to run fully sequential. You don't NEED an engine temp sender - I didn't use one........ it's only really of use during warm up! EFI only REQUIRES a good crank pick up, a multi tooth trigger wheel, an intake air temp sensor, a throttle position sensor and/ or a MAP sensor (to assess engine load) and that's it!

-

2

2

-

-

That translates to about 152hp - which is pretty high reading for a stock bore with CV 36mm carbs. It's even exceptional for an 1100M with 40's.

40's are a pain to set up with anything but std. - suzuki did a good tune with them and don't know of anyone who's used 40mm cv Keihins - so set up advice is gonna be really scarce!

All depends on what you want - good top end with excellent mid range or exceptional top end (that you'll mostly never use) and a mediocre mid range (which is were most peeps spend their time?) Lots try 40's and then revert to 36's or 38's which is sort of best of both tunes.

-

What do you expect the apprentices to do ? As blanks can be anything - hand stamping not unexpected!

-

1

1

-

-

Attractive..................they won't understand - you best explain! LOL

After all these years, you would have thought someone would have come up with a air switch that doesn't break every 5 minutes - the MRE ones are shite!

-

More than likely or any other 'safety related PC bollux' that is fitted! KISS ..... Battery - Ign sw - Kill sw - starter button - starter soli - starter motor - earth ...........that's all that's needed!

-

1

1

-

-

Put mine together years ago but its good stuff - Motec M8, Jenvey dual injectors 46mm dia throttle bodies, 205cc injectors x 8no., 4 tooth ( ! ! ! ) crank trigger - std suzuki 1100 M VR pick-up and Denso Hall effect Cam sensor with single pin in the inlet camshaft. Its so old the Motec programme still runs in DOS and is so antiquated that it won't accept a wideband lambda without a code re-flash by Motec @ £00's - er! No thanks. Ignition was run wasted spark through a dual channel ign. amp to green Dyna coils but 4 channel amps are cheap enough now so it's an easy swop as i've got some GSXR 1000 K3 COPs - if I can be bothered LOL!

I use an Innovate LC-1 with a DTA ecu in my Mk2 Escort.

-

1. Yes. 2. None that I can tell - but I did it anyway. 3. Sequential Ignition may be a bit more effective at lower rpms and cruise off boost. 4. There are very few ECU's that have successful knock sensing and adjustment. Needs quite a bit of computing to continually advance and retard ignition depending on fuel used, fuel quantities, engine and intake temps, vac / boost, battery voltage whilst listening for reliable knock signal as against general mechanical noise!

-

3 hours ago, Askamaskinservice said:

I like your bike.

One question, if you are using a turbo meant for watercooling how are you going to do that?

It ain't required!

-

2 hours ago, Askamaskinservice said:

This was the first that came up from UK.

Ain't particularly cheap!

I generally use ' Vehicle Wiring Products', 'PoleVolt', 'Kojaycat' or 'Planet Auto' - all of them know their stuff & don't talk bollux!

-

3

3

-

-

1 hour ago, no class said:

APE do big case studs

They do but they are still M8's. Bigger ain't needed - the crank doesn't 'walk around' like the GSX ones do!

-

Does that board have the VR conditioner 'built in' - the v0.4 board doesn't - it's an add on? You'll need it with std pick-ups.

-

Short stroke oversquare engines will rev - the 1100 comparatively is long stroke............in 1100 terms. The internals of a 750 weigh considerably less which helps!

-

If the OEM is working - no benefit at all.

-

On 9/7/2018 at 11:48 PM, et1170 said:

ET bracket racing is not an easy class !

I tried telling the SSB boys that waaaay back - no one believed me! I think unless you rely on electronics with delay boxes and air clutches and throttles you have to be killer on the tree 100% of the time, especially with tight dial in's - you snooze......you lose

-

Well that ain't gonna hone or polish out! Std valves are good but they do have an annoying habit of dropping their heads if they get overly hot - something else to check!

-

Most oil cooled exhausts are similar around the headers / frame obviously but the variances come with sumps - some flat, some vee'd and some halved / cut away. Most sumps can be swopped around (with its oil pick-up of course) to fit any exhaust so either buy one that fits your sump or buy sump to fit exhaust.Haven't heard of that Speeduino before - just spent last couple of hours reading the Wiki on it - impressive and quite cheap for a DIY version - I might give it a go. Whilst 36-1 tooth wheels have been used - see attached, the tooth count does get a bit daft at high rpm especially with a VR pick-up....... a Hall device may work better but there isn't much space. I like the on-board MAP sensor that will be ok with a bar and a half of boost but I guess standalone GM 3 bar types could be added in lieu of onboard.

-

1

1

-

-

1 hour ago, Sketch424 said:

Well, one of the turbos in a compoind freds the other, so the drop in efficiency may not be as pronounced as if there were a single turbo setup.

It doesn't work like that - 1st turbo running at 50% efficiency feeds half potential boost to 2nd turbo running at 50% and you still only get half potential boost out! It really is better to use one correctly sized and located turbo for max efficiency and minimal losses!

Compound done correct way...................

And it ends up looking like this......... And no, picture nazis, that is NOT a Yam engine LOL!

-

1

1

-

-

11 hours ago, Sketch424 said:

Maybe having a compound turbo setup would solve the possible low efficiency of turbo, also exhaust wrap is meant to keep the heat in the pipes a bit better isnt it?

Why would putting two turbos away from their energy source help? You end up with 2 having crap efficiency rather than 1!

-

Maybe people that don't like Pod filters - K&N's are my preference - have probably never had carbs set up with them - easier to blame a simple filter rather than their own ineptitude or tightfistedness LOL! CV's certainly don't like individual filters - they seem to like a 'reservoir' of air greater than an individual cylinder capacity.

-

HPF1

in Trick Frames

2 hours ago, bluedog59 said:Something from an obscure Suzuka 8hr or Bol d'Or team maybe ?

Or,

A quality matt black, make people look at the bike rather than the paint.

What like that ! LOL!

-

1

1

-

-

Possibly pistons placed in barrel to keep right piston with right cylinder, pushed past normal stroke ht. and some damp has got in and caused a bit or corrosion? If it is below the 'normal' wear line, a light hone should take it off.

-

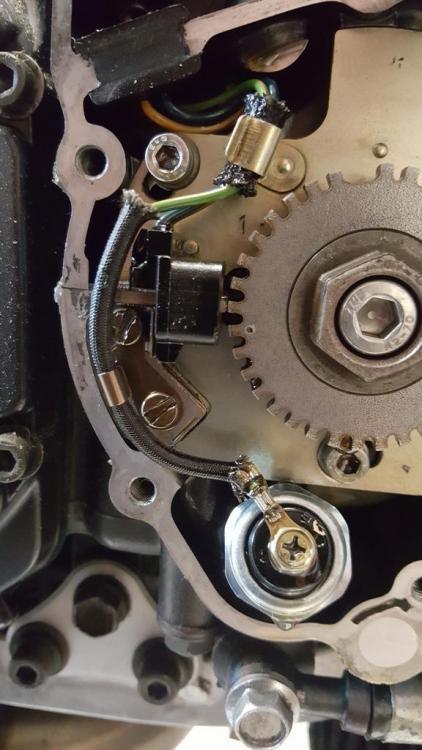

So, it was stuck to the pick-up magnet (steel obviously) in 1st picture and now its not? Did you remove the screw? How could you not notice the 'fairly obviously broken rotor tip' and not pull it off the magnet!

Problem is - it may have picked up a weak magnetic field from the magnet and so will stick (fairly weakly) to anything steel it touches. So IF it has fallen down past the switch, there are a lot of steel bits it can interfere with before it gets to the sump! Best drain the oil and if it's not in that then sump off and pray it's there !

stroker crank

in Oil Cooled

Posted

Not without billet cases I can't. The rods on mine had to be clearanced to the cases and that's only a 64mm stroke!