-

Posts

5,455 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Posts posted by Gixer1460

-

-

On 5/17/2018 at 12:36 PM, August17 said:

If you own a mk 1 1200 you might like to check out "krazy eds cv carb extra 20 hp" I have done this to my 1999 bandit using a delkavic can with the baffle out and original link pipe 20,000 km ago and It gets the old girl going no flat spots and idles smooth . Advancing the timing 4-5degrees sharpens the throttle response to, there is dyno charts showing these mods just "google "

I know Blandits are asthmatic but some jets and a can can't bring the performance to GSXR levels - Bandit 100hp + 20hp = 120hp where GSXR = 125hp? (better exhaust, cams and compression)

Dyno charts can be 'fooled' if you are trying to sell something........ and it isn't difficult!

-

1

1

-

-

17 hours ago, wraith said:

but because of the way the but is threaded it tightens when the bike is moving

Can't remember them having left hand threads? - That's why the lock washer is there!

My old GSX happily undid itself years back - nut facked off and it was a long push back home!

-

11 hours ago, baldrick said:

Thanks for answering but ive since realised its actually on the wrong way /.

I was looking at it back to front after taking off the cover, and looking at it from behind. I said it was facing in towards the engine in the pic but its actually facing out. makes sense now duh.

the wide part of the seal gets pushed by the fluid, moving the cylinder and pushrod..

I'm with you on this - generally fluid pressure on a seal should be to cavity side to push the seal lip into the bore to force a seal - done the other way the fluid just 'washes' past the lip. Harder to get into the bore but that's the point - lots of lube (oooh er misses!) and i'll go in.

-

1

1

-

-

Hmmm! Cam should be dripping with oil or at least wet if it hasn't run for a few days - what do the cam lobes / tappet pads look like? If scored then remove the cam - I suspect the cam journals may be toast! It may also indicate a gallery blockage up to the head on that side ....... more investigation!

-

Very nice torque curve and linear power - should be a hoot!

-

44 minutes ago, Duckndive said:

Lock wire them round the pipe

Or simple plastic cable tie - will eventually melt and fall off.

-

1

1

-

-

Possibly jumped a tooth or three and valves touching pistons? Check valve timing urgently - it won't get better, only worse!

If it isn't, then at least you've checked and can be crossed of list - and it's an easy check!

-

Unfortunately stating the obvious - that's the problem when you drill out the key recess - either can't tighten sufficiently or can't ever loosen!

You could try using a cold chisel or a punch near the outer radius and knock it round? I change that std bolt for a proper adaptor that has a hex on it, it stays in the case and a 'normal' pipe / hose fitting attaches to it.

-

The same number is quoted for the two companies and so is the likely to be the UK importer, and whilst they may offer tech support, I maybe wouldn't trust their advice - player of many instruments but virtuoso of none!

-

2

2

-

-

An in-tank pump isn't essential - maybe neater but more aggro. I use / used external Bosch types - just a bit more hose required.

-

I didn't think an 18T was possible with a 530 chain - all to tight everywhere...... a 17T is tight enough!

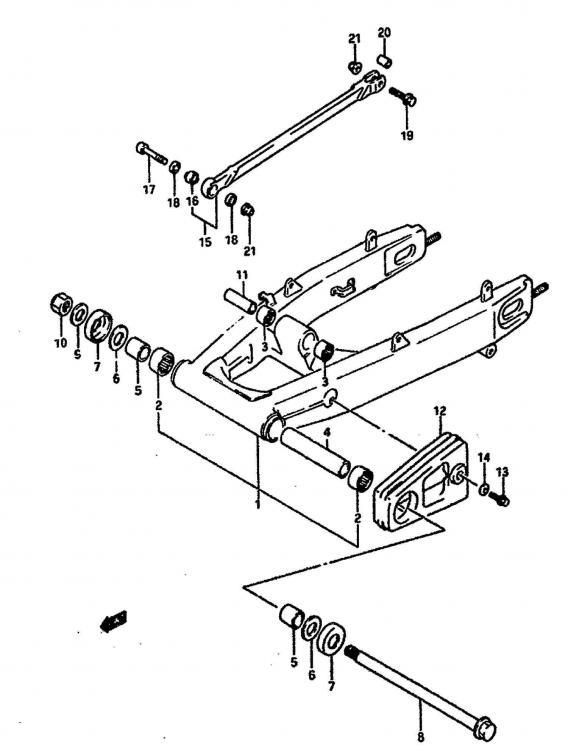

Chain always hit the swinger - it's designed to do that - that what the rubber guide was for - piccy is example - #12

Lot of people use a strip of nylon in lieu of the rubber - use domed or countersunk screws or the chain will catch and that's a world of pain!

-

1

1

-

-

1 hour ago, VJ said:

My dot headed gsx1100g is blowing a lot of oil out of the clutch breather, as in 400ml every 100 miles

What the fuck is wrong? Compression is within 15/20psi across the deck comparing pots.

Oil level was halfway between low and full before it kicked it out on a warm run today

What is the actual psi readings? With a DOT head i'm guessing should be 200+psi?

Was the oil level static - engine off or engine running? Straight breather connection or 90 deg.?

Sounds a lot more than is usual from clutch throw off !

-

1 minute ago, MeanBean49 said:

Ahh ok. Im just trying to figure out how they work. Got to be some way that they multiply reference pressure as it increases, not sure how that is done mechanically, maybe a tapered return or somthing.

I get the reasons, i was just thinking of a ratio of around 1.1, at high boost where it changes quickly just having a 2.5psi difference probably isnt enough to keep up with change. But if it was 2psi at tickover and say 5psi at 20psi boost would help running. Just a thought

Not really as the float valve would see 5psi instead of 2psi - wouldn't stop flow so instant flooding. The pitot's shouldn't give any actual increase in pressure but if they were positioned say, on a section where the pipe flared out / increased dia. the pressure would increase fractionally. I'd say they are best positioned near the compressor to get the 'earliest' signal with most direct hose run of 6-8mm bore to maintain gas speed. Maybe this is why pipot installs show such wide variations in function and efficiencies?

-

1

1

-

-

2 hours ago, MeanBean49 said:

I guess its just different ways we look at things. Rising rate like you describe wouldnt be any good.

Out of interest wouldnt an FPR like that need some sort of electronic control or be quite complicated to maintain a ratio not just maintain reference pressure + base?

Just wondering if somthing like that with a low ratio would work better than regular boost referenced fpr

No electronics..... https://www.fuelpumpsonline.co.uk/fse-sytec-adjustable-fuel-pressure-regulator-rising-rate-2072-p.asp

And for a carb - No, for the reasons outlined above.

-

To get it running maybe but its way to soft / heat retentive to use for general running - its a #5 whereas the correct plug is #9

-

Beg to disagree - Rising Rate regulators increase pressure based on their settings 1:1.2 or 1:1.5 and i've seen them upto 1:1.7 so for every 1psi boost the fuel pressure increases by 1.2 or 1.5 or 1.7 - as I said this is maybe not what the engine wants - sort of if more is good even more must be better!

A boost referenced FPR stays 1:1 so the FP stays exactly as it was without boost in relative terms - you are trying to achieve a constant fuel level in the bowl, how can that be accomplished if the FP is constantly changing compared to the boost pressure within the float bowl?

Re-reading an earlier post this " carbs with a FPR don't need vacuum " was badly worded. It should read " carbs do not need vacuum regulated FPR's"

@El Gringo- pressure is pressure and vacuum is vacuum whatever bore of pipe - only the response time is likely to vary although probably not as you could measure it reliably

-

1

1

-

-

2 hours ago, MeanBean49 said:

You do if its a rising rate FPR, otherwise if you have 3psi fuel pressure and 4psi boost you cant get fuel into the bowls.

Otherwise your fuel pressure needs to be set a bit higher than your max boost permanently. Cant see carbs holding 20psi

READ IT ! - I said VACUUM !

And a rising rate regulator is completely different to a boost referenced one ! The first is used as a 'band aid' for EFI systems that can't be remapped - increasing fuel pressure uncontrolled and unrelated to boost pressure / engine requirements. The latter will increase FP to match boost pressure so that the fuel pressure will remain at static + boost to avoid wild swings in fuel mixtures / flooding.

-

1

1

-

-

Just an observation - carbs with a FPR don't need vacuum - the float bowls should be filled regardless of what the engine is doing. Fuel metering is done by the carb design not fuel pressure.

EFI on the other hand can benefit with a vac referenced FPR as the squirt pressure at the point of injection is proportional to what the engine is doing / needs.

Re the picture above - I wouldn't be surprised that the pitot gave bad results due to airflow disruption from the tube welded on beside it?

-

If the tin tops are aircooled Suzuki then the spacing should be identical to 36mm CV's and 38's and 40's......... 77 - 93 - 77 - centerline dims.

-

1

1

-

-

Excellent idea! Hang on bling always appreciated!

-

Whilst I can sort of see the attraction - that engine has too much 'in ya face' CNC work on it - just me I 'spose! I do like the block ....... apart from the graffiti on it ! ! ! LOL!

-

Hmmm - bit clunky, not what I was expecting. I was thinking more along the lines of a linear potentiometer on a single cable.

-

Ho Ho Ho - out comes the Dremel !

-

1

1

-

-

1 hour ago, markfoggy said:

Funnily enough I picked up a set of RS40's that came off a race bike and were fitted with a TPS - obviously retrofit but proves with ingenuity anything is possible.

-

1

1

-

Maine jets

in Forced Induction

Posted

Well that's a 'how long is a piece of string' question!..............5psi?.............10psi...............15psi ...........more? 1157cc, 1216cc or bigger? Compression / timing / loads of other stuff!

All will have an affect!

If its stockish / low boost you could get away with 5 points more than stock as a good starting point.