-

Posts

805 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by Oilyspanner

-

High compression is the major producer of heat, even with an otherwise std engine - bandit cams will produce more heat at lower revs, because they've less over lap/cylinder pressure is higher at lower revs. Were the cams dialled in properly ? At 60 the air should offset any slight carburation weakness induced heat. A big bore outfit will need more cooling than a std engine.

-

Yep, handling heat is always the problem with our engines, tuning, going slow, lugging more weight just make it worse. Like the extra cooler idea combined with a fan, this would help a lot.

-

Our engines can run pretty hot when tuned, my solo bike needs to move above 30 mph when it's hot outside (28/82 degrees), else the oil temperature climbs. Pulling a sidecar would produce more heat, high compression pistons produce a lot more heat, so that's why you holed a piston .....forged pistons are tough, so your engine must've been very hot ! Jetting is only one part of the problem/solution. Fitting a fan for slow speed, town environments in the summer would be helpful , dropping the compression would help and make sure you don't have an ignition advancer. Fitting gsxr cams would help reduce cylinder pressure at lower revs, it would reduce torque low down, but would lower engine temperature....but sat in traffic it would still get very hot. Fit an oil temperature gauge, then you'll know when the engine is struggling with heat.

-

Hard to tell with those photos. If you have minor pitting on the lobes that you can feel, you can polish those areas and they'll be fine. My 1100N cams had minor pitting, so I did this with mine - check the matching follower surface too. I used fine wet and dry, then buffed them with a rotary tool, they felt smooth afterwards and in 10,000 miles since I haven't noticed any worsening.

-

Could check all the engine bolts, one might be loose - sometimes loosening the bolts (with a Jack to hold the weight) and then systematically go around gradually tightening them up helps. Something that I did to help my right hand was to alter the angle of the bars. I've got clip ons above the top yoke and had angled them back - less reach, more upright for more comfort when going slower I thought....what happened was that my wrists were held at an awkward angle. I pushed the bars away from me and just like that my right hand/wrist wasn't a problem. Obviously you've got std bars, but after market ones can be fitted without changing anything else.

-

An 1127 m/n with ported head, std cams, 40mm CVs will produce a very healthy increase in power and will rev well.... it won't spit out shims with a std igniter unit. Raising the compression helps bump up torque over the whole rev range(not so much at the top), obviously a big bore helps do this and the extra capacity broadens the power even more - it's very noticeable. Standard 1100r cams produce a really good power spread for the 5 speed gearbox. As you've said near the start of this thread, 40mm CVs need an airbox, without it the torque curve is like a roller coaster. I ported my head myself, I did it in 3 stages, so felt each change made, even cleaning up the ports is worthwhile - there's plenty of lumps and bumps that can be removed. Matching the valve seats to the port throats, even apparently small details are worthwhile...it just takes some care and time. Better to do too little than too much. I did most of the work with abrasive rolls, not that much with tungsten burrs. There's only a few tuners who used to port our engines back in the day and still do, obviously they know straight away what works.

-

I've got a blunt straight edge screwdriver I use to push the arm out of the way - it's a doddle when you get use to it. As you said, you have to push the arm against the spring, use the cam journal base to gently push against if needed. It's really easy, although it takes a minute or two to measure the shim thicknesses. I've got a box of hot cams shims, but I still measure what I've taken out and what I'm putting in.

-

Why not just fit larger valves ? No real downsides...apart from the cost, but you've already invested a lot of money..... Larger valves increase torque over pretty much the whole rev range and would help a large big bore engine breath. You would need to blend in the port throats to the larger seats. Cams just shift the torque, it depends what you want from the engine. Standard cams , big valves, ported to suit, with tmr40s would make for a damn strong motor. My 1100n has a 1216 kit, std cams on 104 degree centres, 30 mm inlet valves (Abuso), tmr40s, full akrapovic, my version of high velocity porting (mk3)and some valve deshrouding - it's damn quick, brilliant on B roads - I like a fast bike and to be honest I don't need or want any more top-end, it's shockingly fast for a 31 year old bike. With an extra 60cc there would be more torque, starting earlier, around 100 lb/ft+ of mid-range torque and would pull to 10,000 revs - it probably wouldn't rev out as well as a smaller engine, which cams might let it...but you would lose torque lower down..no such thing as a free lunch !

-

The wintergreen oil and rubbing alcohol mixture does work, put some gs650gt inlet rubbers in some for a day and a half, softened them up nicely....I stunk out the garage, which then spread into the house !!

-

If it idles and does gentle cruise the pilot is okayish, but likely needs more fuel. 5000 revs is needle area and it's the easiest to adjust - try 4th and 5th position and see if this helps. It's likely you need a different needle profile to get it spot on. Buzuki will be right with the m.jet size, you always have to up the size many sizes when you ditch the airbox with CV carbs. Main jets only start working when the motor is really spinning, there isn't enough of a pressure drop to lift the slides until high revs are reached - regardless of where the throttle is. The joy of carbs !

-

Look up Denso coil connectors and they'll come up.#bay normally have them too. If your dual coil system is working well there's no real improvement, but old ht leads and coils often play up, or the caps get loose etc. The wiring loom is very flexible, not rigid like ht leads, so nice to route where you want - you free up a chunk of space where the coils were (can put the main loom there) and it's really easy to get the coils and harness out of the way when you want to remove the cam cover. Starting does seem very good.

-

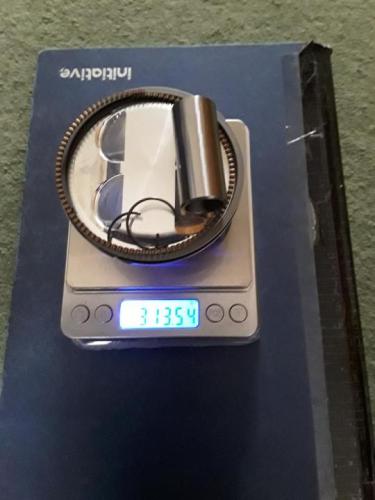

I bought a set of 81mm Wossner pistons, the pistons are only 3 or 4 grams lighter, but the design has a short gudgeon pin, saving a lot of weight , steel being much heavierthan aluminium - saves around 18 grams ! The rings and wire clips are very similar, so over 20 grams saving over my Wiseco 80mm piston assemblies, very worthwhile, giving the crank , bearings, conrods etc an easier time at high revs. Now I've got to balance the set, the only negative is that one piston is 0.9 g heavier than the lightest, I can balance them though. Overall very happy.

-

That makes perfect sense now Nice one Panos.

-

Great info Panos, thanks They're closer than I thought, the braced 1100ws - on , is longer, so will be heavier, but the 750wr/s is very similar kg to the Slingshot, but is shorter, food for thought ..

-

Thanks Bud

-

Hi Panos.....saw you had a number of swingarms, could you please weigh them and post the figures ? I've always believed that the Slingshot arm was lighter than the braced ones. You've probably fitted the 750 by now, but any info would be good. Cheers mate

-

There were a few bikes in the early 2000s that used similar spec stick coils. I've heard that the R6 used a similar spec too. I plumped for the early K series coils as I knew they worked. Converted mine many years back (8 or 9 years)and they've worked very well. My bike's had high compression pistons etc for 5 years and covered 12/13000 miles and the spark seems to coped well with that. Turbo and nitrous probably not though.

-

I tried saving it upside down thinking it might come out correct...but no. So I saved it on it's side, at least it's easier to read !

-

i forgot how annoying microsoft laptops can be ! Had it as a pdf, but swapped it to a jpeg -hope it comes out okay.... Sorry Wraith, I saved the 1st page the right way up, but when I brought it to the page it was upside down...

-

It's a few years since I converted mine to stick coils, but I seem to remember that the resistance on 98, 99 srad wasn't suitable. The k1 to k4 R coils work out very close to 3 ohms when linked in series. There's other makes with the correct resistance coils, Triumph daytona 600 and 650, Kawasaki zx6r...but I don't know which years. If I fire up my old laptop I'm pretty sure I've got the diagram from practical sportsbikes.....which is what I used to do mine.

-

I'm on 104 on each, this gives a very good spread of torque on my engine - have tried a couple of settings. Mine gives nice torque to 3k and very strong from 4k. Lower numbers should loose low down power, but add a bit to the top-end and vice versa. The inlet cam has a much greater effect when moved. Standard cams seem best in a small window, 103 to 105 degrees on the inlet....that's just what feels best and is very close to factory settings....they definitely knew what they were doing !

-

If you could I'd appreciate it

-

Old Suzukis are great to own, especially if you choose one that suits you, you can upgrade them and they're brilliant to ride

-

Hi Daz - that might've been me ! I've got Wiseco pistons in my bike and found out the gudgeon pins were heavier than stock, although the std ones are 3mm longer and needed trimming at each end. I don't know why there's nothing published anywhere on the wossner piston weight - you can find the American pistons with a bit of digging around