All Activity

- Past hour

-

their on fleabay... the just screw in to the oil gallery in the engine... course it depends what model of GS you have

-

- Today

-

Any one know where I can get suchm this is for a GS Thanks Scott

-

joefromnorton joined the community

-

My bad I’ll fix it

-

You are gonna be in trouble - there is no such thing as a 600 Katana! RTFR's

-

Upgrail started following $50 GSX600F engine cooling

-

First post, Hi all, so I happened to pickup a seized GSX600F engine for $50, and I’m in the middle of doing a rebuild. So far everything has been going great, found out engine seized because of a stuck gear in the starter assembly, and I’m currently waiting for a good deal on some 91 gsxr750 barrels and pistons/rods. With plans to eventually turbocharge it. But that’s not what I’m asking here. I’m planning on doing a small experiment by changing either the stock oil cooler over to a oil to water cooler, or trimming off some of the air cooling fins on the barrels to then create a box/passages that I can fill with coolant, then run a separate radiator, pump and overflow. This is all pretty much for s**ts and giggles but I thought it may be good to get some input, I’m not sure if either would be better or cooler but I don’t think it’s worth it to do both. What do yall think? Will I get better operating temps with an oil to water with a thermostat or should I water cool the barrels? Either way they should be beneficial when it’s boost time, but that’s for later, I still got more reading to do on this forum. Thank you posts from the last 2 decades XD and thanks for your input

-

Upgrail joined the community

-

Those seem to be about 0.41mm and 0.46mm. Which sounds pretty much correct. I have been using 0.40/0.45mm for 80mm pistons.

-

Thanks @Gixer1460. Read it again slowly Can you confirm I have my calculation right please. 3.2" bore x 0.0050" = 0.0016" top ring. 3.2" bore x 0.0055" = 0.0018" second ring. Maths not my strong point. No maximum gap mentioned.

-

Thanks for the reply. Will try with this plumbing modification. How would you change pilots and needles? Mixtures are 2.5 turns out and idle AFR is 13.5 at 2k rpm. Needles are 3rd from top. Just tried without intercooler and AFR stays at 13 on WOT with 135 mainjets.

-

Google is your friend (sometimes) - and from the horses mouth! - https://www.mtceng.com/wp-content/uploads/2020/01/piston_kit_installation.pdf

-

Sidestand sorted, headlight issue sorted, stiff throttle lubed and returning freely, historic vehicle V5 back and ready to go. Just been too busy but £83 insurance to pay and we're going out.

-

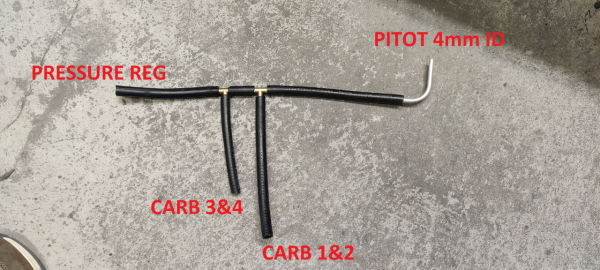

Whole range AFR can't be fixed by changing the MJ alone! Both the pilots and the needles will need attention IMO. re the plumbing, I'd have 1 tee off the main line then split that with another tee to feed each pair of carbs - seems would be more equalised to me?

-

Fitting an MTC kit for a turbo on a Blandit. Can't seem to find a definite answer for ring gaps. Can anyone help who has experience with them maybe.

-

critter joined the community

- Yesterday

-

Today was great as it now rolled along with no issues. A nice warm day in England and it was time to push the bike outside and start again at getting a fuel map into the ECU. The bike fired up nicely and then just stopped. The overboost had kicked in and this cuts the fuel to the motor. BUT WHY ?????. Two hours were spent checking wiring, voltages and air fittings until the motor started again. The pins on the Bosch MAP sensor are very, very small and I can only assume this was the problem so after cleaning, yet another problem was solved. Next week, I can connect the gear linkage, put some fluid in the hydraulic clutch and I should be able to take her down the road. The Autotune function on the MS2 will hopefully help me with the fuel mapping. With its paintwork of many colours and the white and black side panels waiting to be fitted...........I am happy with its progress and the ugly appearance.

-

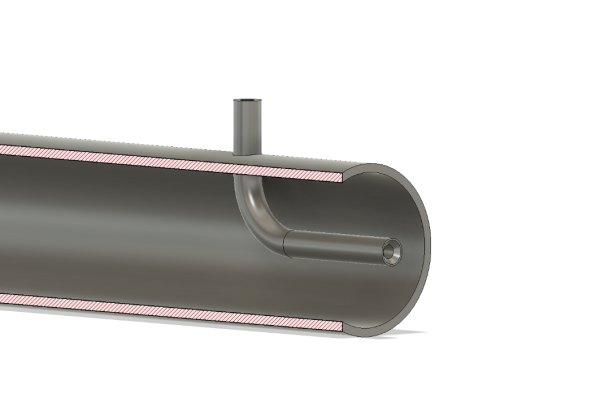

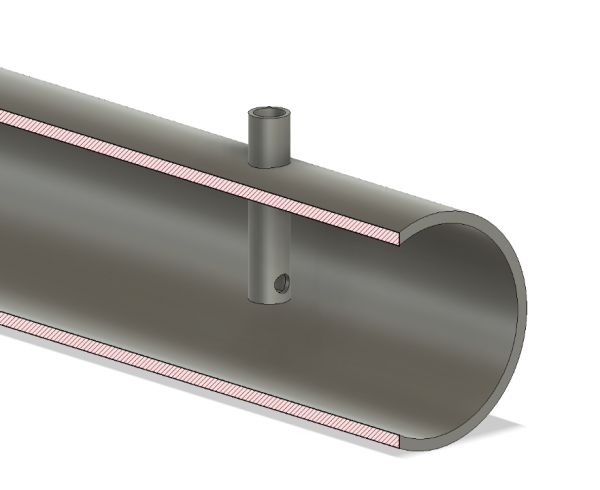

Little update for this year. Took her out from the shed for a quick spin. During winter time I changed the pitot to different style. Previously I used pitot which was delivered by proboost. Problem with this kind of pitot is that, there is a known risk of forming void behind the pitot which will make air to bypass pitot tube when going above 0.8 bar. With this setup, I got good AFR as in the post above. Below is pic of old pitot: I was advised to make a new pitot from a tube with an inner diameter of 4mm, which is inside a 2" charge pipe (charge pipe was not changed). Below is pic of new pitot: Now I'm having problems with getting AFR right with this solution. 125 mainjets: 14-15 AFR on the whole rev range. 130 mainjets: 14 AFR on low throttle (<4k), 12.5 on boost transition (4-6k), 13 on low boost (6-8k), 14 on the higher boost (8k-10k) 135 mainjets: 14 AFR on low throttle (<4k), 10.5 on boost transition (4-6k), 12 on low boost (6-8k), 14 on the higher boost (8k-10k) What would cause this strange behavior? Mainjet seems only to affect transition AFR, not the mixture on top. Heres how my pitot pressure is shared. Is has been working well with old pitot, but not sure if its causing some problems now? Hoping to get some suggestions....

-

15 months have passed since I started this build. In that time, I have spent over 120 days assembling the bike. Some things have worked, other things have broken. Alot of things have just confused me because I have no idea of what I was doing. And I am still struggling with problems. A new fuel pump and modifying the fuel rail have gotten rid of my fuel issues. Fitting a Bandit swinging arm into the Slingshot frame was easy but problems have occurred due to chain clearance with the frame. The chain was also contacting the swinging arm where it bolts to the frame as well. I have also fitted longer dog bones to the rear suspension and a 17T front sprocket and the 50T rear but at least everything works correctly now. The rear shock absorber had a crack in one of the mounts and this broke when I tightened the mounting bolt. I ordered a new part and then had to strip the shocker down to fit it. More time wasted. The picture was taken when I was sat on the bike so you can see why I had to change things

-

-

This is really sad to read. There was a time when there were quite a few specialist frame builders around, but now so many seem to have died off. I've just read a post on rev to the limit about him slagging off other fabricators on facebook in 2022. He just seems like a complete arse.

-

I've had a couple of GSX750's and would have another without thinking. Great bike. Enjoy it. Are you going to modify it at all?

-

A lot of electrical problems are down to dirty/corroded connections. first port of call with electrical problems is always clean all connections and check you have voltage from the ignition. Glad to hear you got it sorted though. Enjoy the 550. I had one and it was a real laugh.

-

Stuart1170 joined the community

-

yes it was somthing like that, i keep meaning to write all this stuff down, but its too late now as i cant remember my name is dave some days!! If I remember corrctly, on the same dyno back in 1997/8 ish my 1200 made 98 HP bog standard, with Dot head cams a race can and filter 118hp and with the head and jet kit as well 130 ish?? I think, ??