-

Posts

178 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Posts posted by rerb

-

-

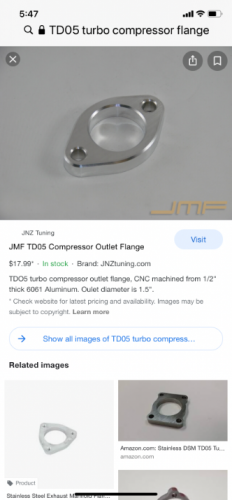

I'll be getting some components for my build from proboost in finland, in an email they said the td05 16g does not require an oil restrictor, is this accurate? I was under the impression journal bearings required one on these motors. Thanks.

-

4 hours ago, Captain Chaos said:

buy an RE5 and you don't have those problems

I would love to. But I'm sure I'll eventually get bored with replacing apex seals

-

On 5/2/2021 at 12:09 PM, Ragerover said:

Not really just stuff the crankcase with clean cloths.

I used to do it the other way in the 80”s and early 90’s

since then I’ve done it this way

the tricky think my traditional way is when you space the rings correctly getting the oil ring in.

both ways are doable and I’ve done quite a few of each.

daft as it may sound I always take the motor out for barrels and pistons or shims and do it on the bench .

I find this quicker and easier too

plus you are working at the correct height

I ended up using hose clamps to clamp the rings. Was over in 15 minutes, I struggled to get the wrist pin through the conrod trying it with the pistons in the barrels

-

Hi, I just finished piecing back together my b12 after rebuilding it for a turbo. It runs great, other than when I come to a stop the idle wavers around 3k for about 5 seconds before dropping to 1k. While riding it, If I pull the clutch in or put it in neutral, the idle will stay at 3-4k and won't drop down. I have the vent bowl breathers tucked in the notch of the airbox, and all vacuum tops capped except the one to the gas tank. Airbox is on with a k&n filter, and the exhaust is off a merge collector header without the turbo. Obviously the lack of exhaust leans it out a bit, but when accelerating it feels perfect. Could that be the culprit? Or are there any other carb ports than may cause this, I might've missed something while rebuilding them.

Also, choke cleaner finds no air leaks. Thanks.

-

6 hours ago, Gixer1460 said:

Against the whole mass of the clutch, that little piece missing will make knob all difference! Holding tools such as this type are best used with two pairs of hands - as you now know!

No kidding, good to know, thanks

-

Torquing down the clutch nut on my bandit 1200 with the ebc handle and suddenly both my hands were on the bench and my knuckle was bleeding all over the place.

Pretty sure this break in the tool slot caused it, is it fine to run or is the very small amount of missing weight going to screw with the engine while it's running? thanks.

-

Cases split, tensioner installed. I pulled the cylinders/head just to verify everything. Glad I did, I guess the oil passage o-ring didn't seat properly in the head and was completely mangled. That would've caused a leak for sure.

8 hours ago, Gixer1460 said:You might be able to lift the barrels just enough to slip the tensioner seats into position - its awkward but saves the chance of a busted ring or two!

As for fitting pistons - get 2&3 atdc, slip barrels on sitting on top rings and gently ease rings into barrels with thin screwdriver & fingers. Gavity works for you as will push barrels down on to next ring set. Once 2&3 are done, rotate crank whilst moving barrels with pistons till 1&4 slot in and repeat although space is V limited! Enjoy!

I'll try this method, I started with 1&4 and was having a lot of trouble with 2&3. As far as compressors go, if I can't get em by hand I'll try some hose clamps.

Another quick question, since the engine wasn't started I know I'm fine to reuse the MLS head gasket, but what about the copper base gasket? I used gasaginch and now it's dried all over it, would it be necessary to strip it all off? thanks

-

Get ready to laugh at my colossally dumbass move, but after completely rebuilding my motor to the cams I realized that the tensioner side cam guide installs in the bottom end while the cases are split, not the head.

Back to the jungle I guess.

While I'm here, any tips when it comes to installing pistons to the cylinder? I don't have the fancy ring compressor in the manual. Since I gotta do it again.

-

1

1

-

-

-

-

-

-

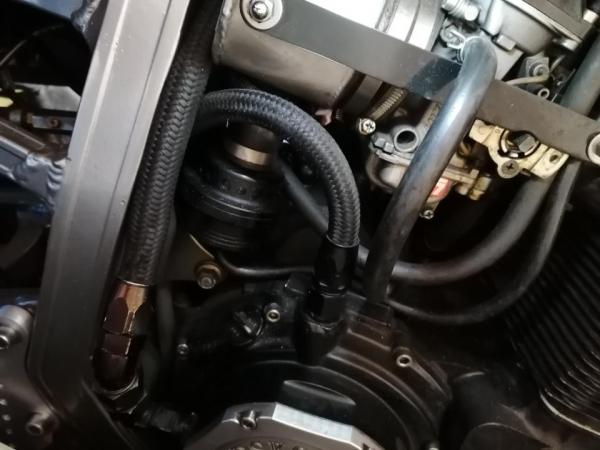

Hi, I've been plotting out my oil lines for my turbo and have the feed all figure out. But I'm a little confused on the drain. I'm pretty sure mine's too high for gravity drain, and I'd be more comfortable with a pump anyways. Know a lot of people recommend a mechanical crank driven pump, but those are too expensive for me right now.

So my question is, with one of those $50 electrical pumps would they be strong enough to pump the oil upwards into the clutch cover oil fill plug? I see a lot of people run them to the sump but I'm not sure how that would work with static oil level. Another question is if I could drain it into an oil cooler line with a split or a 1 way valve, or will engine pressure override the pump and result in me having 2 feeds?

I know a crankcase breather is important and I see they make some from the oil fill cap, but I don't see any other place for one so I'm not too sure where my drain would fit into the equation. And catch cans aren't necessary for a drain with a pump if you run the pump on an independent circuit for few seconds after the bike is shut off, right?

Any clarification would be appreciated, thanks.

-

Well I did the math and buying a proboost manifold + a Chinese td05 would actually be more cost effective, so I think I'll go with that, fabricating one looks pretty difficult. Thanks guys

-

52 minutes ago, Gixer1460 said:

Probably because - as I said - he hasn't got the guys to do it!

True, he said they're booked up with full kits, in January, still gonna ask again though

-

22 hours ago, Gixer1460 said:

Wouldn't it be possible to cut the Proboost manifold connection off and add the correct one to suit the turbine outlet of the TF035 (not a number i'm familiar with?) All depends on the manifold material as to which process is most suitable and of course skill level! MIG is a 'ghetto' solution, TIG is more elegant with a better appearance but both will do the job! I know Sean at BigCC had most of his fabrication guys either let go or furloughed and is barely keeping the business going - I'm sure he'd welcome the work if he had staff / people to do it!

I'll try and send him another message to see, he told me he couldn't about a month ago

-

-

The last major piece of my turbo bandit puzzle is the exhaust manifold. my turbo is a tf035, which doesn't fit the l proboost manifold. I've contacted big cc and a few others, and either got no response after a week or so or was told they couldn't make one at the moment.

I'm pretty new to welding, and only have MIG available. would it be possible to weld up a manifold with MIG instead of TIG? making my own seems like the only option without spending $700.

Thanks.

-

For busa pistons on std rods, should I used the wrist pins that came with the busa pistons, or the ones that were originally in the motor? thanks.

-

4 minutes ago, clivegto said:

@rerbI can hear this one.

but not this one.

but not this one.

looks good, thanks!

-

On 1/13/2021 at 2:30 PM, clivegto said:

Depends on where its mounted, got a picture.

Haven't mocked it up yet, would probably sit around the left knee

-

On 1/13/2021 at 2:49 PM, Gixer1460 said:

And whether you want to sound like a dickhead furry dice, cage driver with two missing wheels! Never heard mine and it was by my left knee!

of course I do, im 17!

no, but I got a used sequental BOV and just wanted that little tickle of noise at low speeds or free revving, oh well

-

Just curious about whether or not you guys could even hear your BOV go off. Personally I'd like to be able to hear it, but im assuming the wind noise and exhaust noise would overpower it. Anyone have a different experience?

-

On 1/11/2021 at 3:23 AM, MeanBean49 said:

Its funny, I was following that FB thread too, and if you get into it, the person saying top end oiling kit fixed their issues, actually failed to mention that they had previously also trapped the oil o-ring washers on top of the studs, which is what actually caused the issue, they fitted the oiling kit the same time they sorted the orings, and believe the kit fixed the issue not the o-rings.

My take on this, the oil "feed" kits actually tap into the low pressure system and supposedly feed into the high pressure system. Given that the low pressure is less than the high pressure, whats actually most likely to be happening is you bleeding off hp oil back into the lp system so in effect are reducing the oil supply in the HP system (crank as well as cams) in reality it probably has little effect given the pump should have enough capacity to cope. But the kits are nothing more than pointless bling.

Suzuki designed the engine and are pretty switched on, Im pretty sure if a few banjos and some pipe made an improvement to the oil system they would come from the factory like that.

Regarding the stud size causing a restriction, have a look at how big the hole is in the oil jet where the barrels meet the crank case, all the oil to the top end goes through those, and im sure if it gets through that ok, it will get up past the studs fine (just make sure the o-rings at the top leave a gap round the studs)

I have a pretty good idea how it all works, but if im in doubt I just look at the setup suzuki went with on their race bikes, if anything worked better it would be on them.

Regarding oil supply for your turbo, i found it easier to use carb jets tapped into the banjo on the take off, I start fairly big, so turbo smokes a bit and downsize in small increments until it stops, then take the return pipe of and run it check theres oil going through the turbo. Never had a problem, not all turbos are the same.

Thats my input anyway

Aha, that'll do it! thanks for the turbo advice too, sounds like a solid method

Any experience with proboost kit?

in Forced Induction

Posted

Good to know, I think I do see a restrictor in the turbo. My setup is mixing/matching kit parts and custom parts so I wasnt sure if it had to do with their modified turbo, their oil line, or any td05. Thanks.