-

Posts

178 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Posts posted by rerb

-

-

On 11/14/2021 at 9:43 AM, 1260Pete1 said:

Yep most redirect it back into the I take, I run all my cars without and the sound is much better.

I deleted the diverter valve on my audi, it sounds great. But it also hurts spool time a little. I was much more confident doing that on a car than a bike, because the car has a single, beefy butterfly valve, and the bandit's carbs have the more fragile slides as was previously mentioned.

I have found a nice in-between though ,the HKS sequential blow off doesn't fully open below 6 or so PSI, so on low boost I still get some nice flutter but at the same time I still get that satisfying "chirp" from it at high boost

-

Good advice, i'm up to 15 psi now after removing the exhaust and some fueling tweaking, so far no weak spots in the AFR in boost. Thing boogies. Ran a 7.2 1/8th mile @104 mph with no launch while crossing the gates in a 3rd gear powerwheelie at 7.5k rpms. To get any good numbers a longer swinger would be required. As for the comment about boost during peak torque, I understand that high boost in lower rpms can over torque the motor, but if peak torque is far up in the rev range, is that something to concerned with? my turbo's a lazy bastard so I only start to come into power at about 6k -> 10k, although it does build to 10 psi pretty quick.

And an ignitech box with dyna coils is the next priority, solely to have access to timing curves, limiter, and stronger spark. (and 2step for the launches

)

)

BTW the motor has busa pistons, APE head studs/nuts and a HD cchain. So it's decently prepped for some good numbers.

-

+1 on std busa rings and 15 psi, no issues yet after 2.5k road miles

-

1

1

-

-

Hi, yesterday I had some free time and ran some tests.

With my exhaust (Vance and Hines muffler on 2.5" pipe) fitted, I saw 12 psi in first, 13 in second and beyond.

Afr in boost was around 11.

I did 3 runs and got the same result.

I took it off, and there was a massive world of difference. I was hitting 14 psi in first, 15 in second, and I saw it tickle 16 in 3rd before I browned my pants and let off mid wheelie.

Afr was around 11.5 - 12.

Same thing, did 3 runs and used a gopro to verify what the gauges were reading.

So obviously less exhaust = more power. A lot more.

I assume the backpressure is putting resistance on the turbine wheel, choking it out. This would make sense as it's a larger turbo. My question is am I stuck with a loud bike to run these numbers, or has anyone figured out a setup where a muffler doesn't affect boost as much?

Would a smaller turbo be choked out less? I also have a thought that maybe the leaner running from less exhaust adds to the power.

Just food for thought here, anyone with a muffler please chime in and tell me what you've found, thanks. I know the Vance and Hines one is pretty quiet, maybe there's a higher flowing one that works well here? Thanks.

-

Well I'm partly an idiot.

I took another look today and noticed the wastegate actuator actually managed to get stuck against the frame, propping it open about 1/2 of the way.

I guess boost pressure was enough to open it fully, but on the return the friction must've held it in place somehow, I have no clue.

Readjusted the mount and now it clears by a few hundredths, bike runs a lot better now.

Still not sure how that even happened unless the manifold sagged with the weight of the turbo

-

3

3

-

-

6 hours ago, Gixer1460 said:

I think you've misplaced the decimal point placement! - at 3.6mm ring gap you'd have no compression to speak of!

Rule of thumb - 0.004 - 0.005" per 1" of bore dia . . . . . so for 78mm, call it 75mm or 3" = 0.004 x 3 or 0.005 x 3 = 0.012 / 0.015" respectively

which equates to - 25.4mm / 1000 = 0.0254" x 12 or 0.0254 x 15 = 0.3048mm / 0.381mm

The above is usual for Normal Aspiration - Forced Induction can afford to go a little looser but you will get more blow by so 'swings and roundabouts' !

Yep, I was off by a hundredth whoops. I went smaller on the ring gap for forced induction because my motor has never gotten hot before, and it's a very cool climate around here. Depending how my bore looks this winter I might go bigger, but so far no problems. I do have a larger piston to wall clearance though, .005". No signs of piston slap yet even though my machinist warned me about it

-

1 hour ago, Reinhoud said:

I ordered new piston rings.

Bores aren't anymore what the were.. I don't have a clue what the gap should be with forced induction and being air cooled..

What do you guys run? 0.5mm?

Bore is 78.33mm if it is important

Thanks

I ran .14 inches on the top ring, so about 3.6mm

-

1

1

-

-

3 hours ago, Reinhoud said:

You have the balls to go WOT in 1 and 2?

When I had the TD05 on it I only had the guts to go WOT in 3rd above 100km/h, and still it did some fish tailing..

Damn I'm a sissy..

When it was running great I didn't lol. That's how I knew something was up. I could lift the wheel in 3rd but now it stays down in all gears

Doing a lot of headwork this winter and hopefully switching over to a td04, what would you guys recommend for a td04 capable of 250 hp? I see 14t is a common choice but not sure.

-

1

1

-

-

Think my turbo blew a seal, started spewing oil into the charge line. I'll check compression too but I think there's crossover between the hotside and coldside because just the day before it was a total rocketship. Motor feels the same before boost but I'll still check compression.

-

Hi guys, my bike has seemed a lot slower over the last few days. I've noticed if going wot from first into top of second, I'm only building 10 psi. (Wastegate set to 14) This is with +1 -1 longer gearing BTW. This seems low, and the bike feels a lot lazier too. In 3rd to 4th I can tickle 13.

My current suspects are small boost leak, boost controller, or failing turbo. When I disconnect the charge pipe before the plenum with the bike running and cover the side that connects to the turbo housing with my hand, the bike dies. If I blow into the plenum, it comes out of the pipe that goes from the compressor to the plenum. I thought it would go through the turbine side of the turbo, not the compressor side. Is this a sign of a fucked seal? Thanks.

-

4 hours ago, 1260Pete1 said:

The td05 16g is not a great turbo, it's lazy and unfortunately has different flanges to every other turbo out there, a td04 13t is what you want and will give you the sounds you are looking for and also make up to 280 horsepower max but still hit hard low down as Clive will tell you

Sounds like just what I need. Sadly that means dropping money on a new manifold, but it'll be worth it

-

4 hours ago, 1260Pete1 said:

For 250 all you need is to update the pistons and turn up the boost

update? I have busa pistons in with the shaved down valve pockets

-

9 hours ago, Goo'Roo said:

My experience with a similar setup:

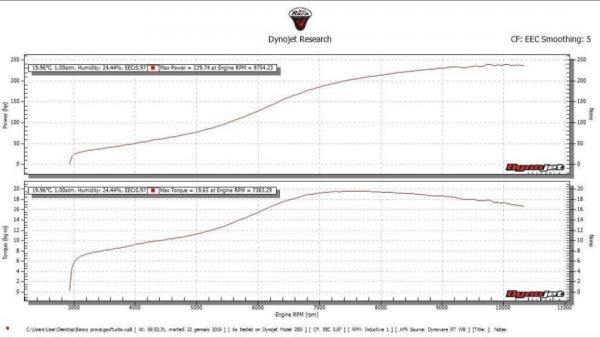

Busa pistons, 0.5mm skimmed block, Chinese cxracing td05-20g turbo (a really slow spoolup turbo actually), ported gsf1200 head, gsx1100f cams, ape studs, 36mm carbs, big volume, dual chamber plenum, Ignitech CDI mapped with map sensor, and I made 240bhp at the wheel with 0.8 boost of pressure, that I consider pretty good values considering no intercooler and the "low" boost pressure.

ooh that curve looks very nice. May I ask why you went with a 20g as opposed to a smaller turbo?

Looking into it, getting an ignitech CDI seems cheaper and better than a dyna2000, something I want to do this winter. How big of a pain was it to install? the dyna seems very simple without the need of a custom triggerwheel, and lets you keep kickstand switch function. Are you running stock coils too?

-

10 hours ago, MeanBean49 said:

Yeah hes talking absolute shite lol.

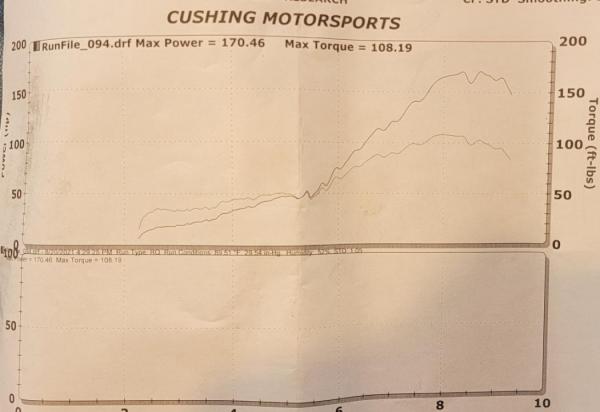

Shame youve not got the AFR trace on the graph.

Peak looks to be around 8k so fairly high up rpm range. GSXR cams probably ideal.

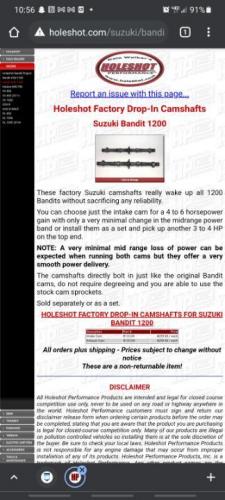

I see on DW holeshot performance they have "factory drop in cams" that sound a lot like their gsxr cams. Anyone have experience with them?

-

12 minutes ago, MeanBean49 said:

Yeah hes talking absolute shite lol.

Shame youve not got the AFR trace on the graph.

Peak looks to be around 8k so fairly high up rpm range. GSXR cams probably ideal.

Yeah, I had only a dump pipe at the time so nowhere for the sniffer to sit. It's on my list to get another dyno run in for sure.

But as far as the cams though, if it will help me make more peak power without more boost, I'll gladly do it. It might not be necessary for 250, but with a ported head, I just don't want to push more than 13 psi for reliability concerns.

-

12 hours ago, MeanBean49 said:

Where was your peak torque? What shape was the curve?

Was barely running, all those bog makes are from 8-9 afr. Put smaller mains in, huge power boost just from fixing the mixture a bit, but haven't had the chance to dyno it again. Dyno operator said he's noticed that the dyno reads about 10 hp less than you'd feel on the street because of air velocity, not sure if true or not.

-

9 hours ago, MeanBean49 said:

I would stick with what you have and invest 8n some dyno time before dicking about with cams. They need to match where your turbo is working best. You can end up killing low down torque because your cams are too extreme, and also loosing top end power because when the cams work the turbo is done.

Ideally you want some dyno time to see exactly whats going on and where you can improve before you dive in.

I run a VF23 IHI on mine and 300bhp at 9000rpm is where it stops, but it makes peak torque of 200ft lbs at 6000rpm. Thats with bandit 1200 cams, I tried gsxr 11 ines and it dropped peak torque down, and made no more power because the turbo was already at its limit.

That makes sense. I actually had mine dyno'd and peak power was at 9k, then sharply fell off. Sounds like a replacement set of stock cams is best for me.

-

4 hours ago, Olekat said:

T25 from a 95-99 dsm might be what you're looking for. The cold side is different but the turbine housing is the same bolt pattern

Thanks, thats the source of the turbine housing pattern I was looking for. Unfortunately I can't find a ball bearing version thats still in production, so I'm going to swap over to an exhaust manifold built for the housing of the VF series turbos.

-

7 hours ago, Arttu said:

Well, yes and no. It's true that you can make pretty good power without high rpm. But if you want even more power without running stupidly high boost then there isn't much other choices than keeping the torque up to higher rpm.

Cam selection with turbo is somewhat complicated since the turbo choice affects on how the cams work. Traditional wisdom about short duration turbo cams is true with smaller turbos that run higher exhaust pressure than boost. But if you can keep the exhaust pressure at the same level with boost or even lower then the cams work more like on N/A engine.

But yes, for that 250hp target I wouldn't use anything hotter than stock GSX-R1100 cams.

Right, thank you.

13 hours ago, Gixer1460 said:With a turbo you don't need high rpm's! My biggie makes peak between 8500-9000! Unless a cam is specifically ground for turbo use ie. lots of lift and short duration it'll probably be worse - overall - compared to a std. cam, I'd stick to a stock 1100 cam for the output you want.

I wrote that a little weird, I meant more with helping out in the 9k rpms area, not taking it to 11k+. I know the b12 cams are a little different for midrange power (atleast thats what I was told) so an 1100 sounds like the right swap.

-

7 hours ago, Arttu said:

The mentioned bikes weren't built by me. I just made engine management installation and tuning for them. So I don't know all the exact details about the engines.

One of them had ported Bandit head, some "hot" WebCam cams and Holset HX35 turbo with external gate. Another one had GSX-R1100 head with oversize valves, stock GSX-R cams and TD05-20 turbo with internal gate.

Yes, a TD05-16 should be fine for 250-300hp so I would leave that alone for now. Sounds like you have the most important stuff inside the engine done too. Hotter cams might be a good idea if you have to replace them any ways. That should help to keep torque up at high rpm. But I wouldn't go too extreme with them. For example that one with Web cams was a pain to get mapped properly at the mid rpm range and still didn't give too amazing power figures at top end. I think stock GSX-R cams could be a good compromise. Increasing the compression and tightening the squish clearance could be a good idea since the Busa pistons result very low compression and pretty bad combustion chamber shape. But then you need to be more careful with tuning...

Right, good places to start. thank you. I've seen GSXR 750 and 1100 cams used on different bandits, anyone know which is best suited for turbo/high rpms? Thanks.

-

1 hour ago, Arttu said:

So, the starting point is a stock Bandit 1200 engine? In that case I think the pistons are the first thing to upgrade inside the engine. As far as I know the stock pistons can't handle much boost. I think the stock rods should be ok for 250hp but if your budget isn't too limited it might be a good insurance to upgrade them too. Just in case if you end up wanting a bit more...

For making power 250hp should be still quite easy even with relatively stock engine. For reference I have recently tuned a couple of Bandits and both made about 300hp at 1.3-1.4 bar boost. Although both of them had ported heads and hotter cams but I think even without those you should be able to get 250hp with about 1 bar boost.

Few things that will help to make more power at lower boost:

- Select a turbo that will work at good efficiency range at your target power.

- Pay attention to exhaust manifold design, especially to collector part.

- Same with the plenum, enough volume and even flow between the cylinders.

- If possible, use some charge cooling. It will help especially if you run more that 1 bar boost.

What cams did you use? mine are rusting/pitting on the lobe, and the chrome on my rockers are wearing off, so that's definitely on my list. (motor had 68k miles before turbo) I have busa pistons and APE studs and nuts. Other than that and an HD camchain, the motor is pretty much stock. I'm currently running a td05-16g, which I believe can handle about 300 hp before running out of breath. Do you use an external wastegate?

-

9 hours ago, Gixer1460 said:

If you are 'hitting a wall' @ 120-130 something is wrong or you are whimping out LOL! My old donkey Kawazuki, naked, w / flat bars, Suck through T2 garrett, S&S carb and 10psi = 200 and a bit hp, would hit 155 and probably a bit more if it wasn't for the parachute riding position! Engine had a 1186 kit + 2mm spacer plate due to 12:1 CR pistons, std. crank, std. rods, std. K/L head and std. cams with a Dyna2000 ignition.

Std rods and cranks will survive 270-280 odd hp - AS LONG AS THE OIL SUPPLY IS GOOD - lose that and the big ends get toasted and will exit the block! Forget all the flash stuff until you are pushing 300+hp or 1.5 bar + boost - really not necessary. A good ported head will help pick up hp while using less boost. Plenty of peeps using carbs upto 300+ hp so EFI not necessary - it just helps tuning and keeps AFR's more accurate.

She went to 150 decently. My concern was on my buddies modern liter bike the acceleration as pretty constant to 140ish. Mine shoots up to 120, but then drops off fast. my 60 - 130 time was measure at 6.3 seconds, but my 60 - 120 was around 5. It gets slower from there.

Thats good to hear about the carbs though, more money for my ignition setup. As for the oil, other than ensuring the jets/passages are clear, what else can be done to the oil system to ensure it's "good"?

Thanks for the good info.

-

Hello, I can confidently say I'm addicted to boost. We had a quick drag event and I never wanted it to end. Currently I'm pushing 190ish to the rear wheel, but I'm a little unhappy in how hard of a wall I hit around 120-130. (Naked problems) Obviously the only answer here is more boost.

I've seen many builds above the 250 hp mark, but my question is with a properly tuned efi and good standalone for ignition, what else should be reinforced on the motor? I see the use of busa rods with a 2mm spacer, would just the spacer allow for a low enough cr? Are busa rods really that much stronger for it to be necessary for the 250 hp mark?

I've also considered that HD valve springs might be necessary, wouldn't a lot of boost have the possibility of holding the intake valves open?

Depending on the cost of aftermarket rods, I might get a set of those. I've heard bad things about certain brands though.

another thought of mine is finding a way to use my 13 psi more efficiently. Obviously on carbs it's tuned rich to avoid any flukes in fueling blowing the motor, so I lose some power there. I've seen the forum of gas flowed heads and GSXR cam swaps doing some good work for turbos, but are there any other secrets with charge piping, intercoolers, or plenum design that wouldn't necessarily require more boost for 250 hp? Unfortunately my manifold flange is sorta "unique" so the vf ball bearing turbos aren't an option for a better spool.

so with all this said, I ask of any recommendations to help me safely reach my target number, thank you all.

-

Bike's away for winter, anyone know a good place to get my head ported?

in Forced Induction

Posted

Hey all, after a good first season without blowing the bike up, the temperature has dropped and the snow has come.

I've put the bandit away, but plan on doing some upgrades this winter. Does anyone know a good spot where I can get my b12 head ported for a turbo application? I'm having a hard time finding a local shop, and wouldn't mind shipping it and not having it for a few weeks. Before I choose one somewhat nearby, I'm curious if anyone knows a place that specializes in these bikes. Thanks for any recommendations.