-

Posts

1,921 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Posts posted by Joseph

-

-

Quick question

Got my hands on the last bits for the plenum : the intake pipe

I have a 10mm OD tube for the pitot. I chose that because thats what recurrent info i found online (i still have no idea what I'm doing, i'm just going by what stuff i find online and especially here)

Any preference based on these three angles ? (On Ol' Red the tube was inline with the plenum intake, like the first photo, for example) Or do i just choose whatever suits the space i've got ?

Would i need to do a slash cut on either of those setups or just the 45 / 90 degree ones ?

Ta

-

Can't do dyno either. Nobody offers dyno carburetor set up in the country i live in

-

1

1

-

-

7 minutes ago, Upshotknothole said:

Dual pods will make it run a lot better.

I saw that you wrote that but unfortunately i'm going to have to stick with the singles on this bike

-

7 hours ago, TonyGee said:

my setup on my zed project.

B12 engine and carbs.

ive used the airbox rubbers (of the airbox) and 4 ramair sponge filters.

150 main jets

needles in the highest position ( clip in the lowest position )

mixture screws 3 1/2 turns out (you might have to tweak them slightly)

exhaust, black widow headers and link pipe, cheap Chinese end can.

bike runs great right up to 7000rpm. haven't had it any higher than that as run out of road where I live, but I think it will pull up to the limiter no problem. plugs look good after a plug chop.

Currently trying to set up my 1127R engine with BST34

I have KN single pods and the exact same exhaust as you, currently on 140 mains, 3 turns and middle notch needles, it's sluggish when you try to give it beans, so sounds like i need to up the game ?

-

1

1

-

-

Yes it goes through to the other side, the Ignition itself is not in an oil bath but there is a small passageway to the sump. It's a really smart and trouble free solution

-

1

1

-

-

5 minutes ago, Toecutter said:

Looking good so far. May I ask what the fitting is for on the ignition cover?

https://oldskoolsuzuki.info/forums/topic/20173-scavenge-pumpwhat-you-using/

-

That is a 10mm spigot, used with 10mm 1/4 turn valve

-

1

1

-

-

Got a few last bits from the laser cutter :

Since the GSX1400 doesn't have cam oil ports on both sides of the head i had to come up with a solution :

-

4

4

-

-

The problem with finding an adaptable one is that due to the mounting position it needs to be super long with a super long stroke.

Like it's been said Hyperpro carry one that meets the specs. Ohlins also has one in their catalog but you'd have to have it made to order, which is possible over this side, probably you can inquire at the official supplier where you are

Otherwise another solution is to fit one accross the forks, hidden in the fairing, you need to weld/fabricate a mount on the fairing stay or something down those lines, but then you can use any short damper commonly found

-

The damper on the 1989 1100 can be rebuilt because it can be taken apart/unscrewed. All the others are crimped, so not straightforward for a home mechanic

The slabside dampers were much better and can be adapted.

But unless you're on a mission to restore to original specs like said you'd be better off buying new and aftermarket

-

1

1

-

-

45 minutes ago, Duckndive said:

I'm assuming you had the plate laser or water jet cut ?

If so who did you use ?

It's laser cut by company local to me in France

It's 2mm stainless and i don't know if i got lucky because often laser cut gives a notchy edge but the few i had them do of this part came out great

-

2

2

-

-

Ok. I'll see about it probably this weekend

-

Haha. Thanks

I'm just wondering whether K3 and K4 is the same ? If so i'll have a look at his bike

-

My next door neighbour has a K3 1000, if thats any good he'll definitely let me fondle it's back end for you

-

Plenum base is looking nice too

-

8

8

-

-

Spigots are pressed into the base plates, now getting ready to send all the ally bits off to the TIG welder since welding is not my greatest talent, aluminium welding is not possible

Also visible is the amount i can take out the cylinder head to open up its intake potential by matching the 36mm carbs

-

5

5

-

-

The rack got stretched

Just a mock up build, i needed to see how long a tab i needed to weld onto the carb nº2 butterfly control, because as you can see it way out.

Choke bracket also needs doing.

Luckily enough the two mega long 6mm screws are long enough to thread into carb nº4, so thats a thing I don't need to address

-

4

4

-

-

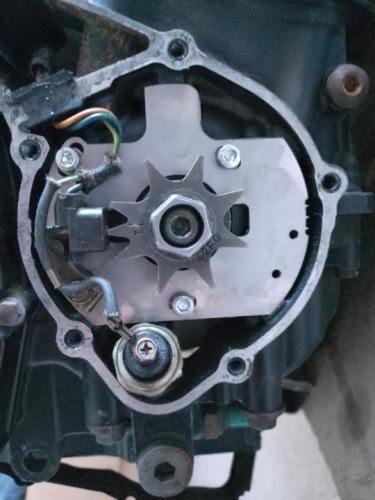

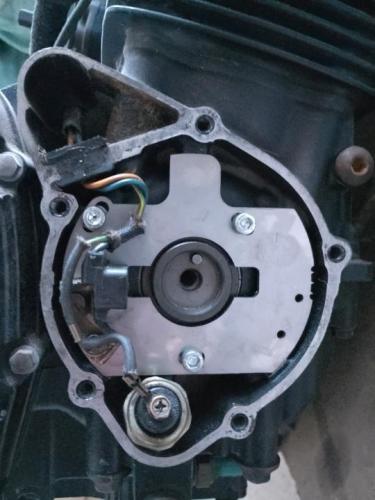

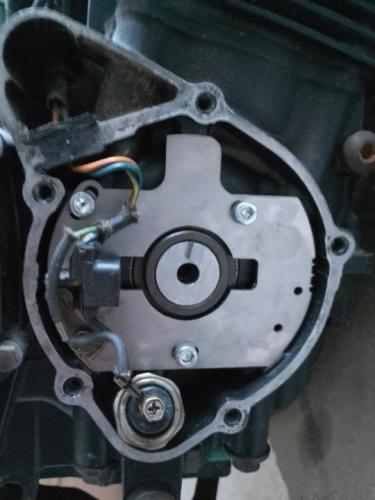

Also pictured is the adjustable advance ignition plate i designed. Didn't invent the concept but it's come out super clean, adjustable +5 to -5

-

1

1

-

-

-

A bit of an update.

So, when i need lathe jobs, I have to spend money on a man because i don't have the tools or know how to machine parts, but he's delivered once again

Alloy spigots for the intake pipes and plenum outlets :

And the parts required for the caburettor conversion (spacers, mainly, because 2 and 3 carb need a big gap added), along with a nice little extended alloy T junction feed to fit with a brass spigot for the fuel feed :

Finally, this little jobby to make up for the difference in height of the bandit rotor compared to the 14 rotor :

So unless i've completely forgotten about some major aspect of how an engine works, this is all that is needed to convert a GSX 1400 to Bandit 1200 analog engine management ?

I'll put it all together tomorrow, it's getting late now I'll probably arse something up if it start now

-

4

4

-

-

-

16 minutes ago, Pegleg said:

Have fitted an 8mm fitting too the tank. The stock tap does look restrictive.

On my turbo 11 when i did the clean up rebuild, i sold the stock tap because i didn't need it, and fitted one of those spigot set ups i showed you the other day.

10mm spigot.

Like on my normal bikes i used a piece of fine stainless mesh to act as a tank filter

The electric pump couldn't draw enough through that, it was bottoming out, i figured that out because on test rides, i could only do an exact amount of meters before it stalled.

That mesh is sized around the same gauge as the plastic tap mesh filter, znd works fine on my normal Suzuki, but the electric pump was having none of it

Took out the mesh and put a car filter inline and that was settled

-

This is be where the pegs would be if you did the reverse operation.

-

GSX1400 engine Turbo project

in Forced Induction

Posted

Cool. That makes total sense.

Thanks for the clarification

Now it's off to the welders then