-

Posts

957 -

Joined

-

Last visited

Reputation

2,123 ExcellentAbout Kid Kearsley

- Birthday 06/29/1987

Personal Information

-

Location

Chester

Recent Profile Visitors

2,872 profile views

-

Looks brill

-

Could you link me up to that seat unit please? Cheers

-

Head saga almost over. The Head I tried to get clean just wasn't going to be clean enough. Managed to drop lucky with @Katanahaving an old slingshot head that required so love, many thanks for that, and @jbfor being the halfway house on it. Set the boy to work on this one. Got it stripped and degreased. Have spare damaged heads that I used for parts. Assembled the best of a bad bunch and cleaned um up. Head is assembled. Just waiting to hear back from the machinist now that the rebore has been done and I can start putting the rest of the motor together.

- 171 replies

-

- 11

-

-

Just gotta holesaw the wastegate into the elbow then tack on the last.... Flange... For the wastegate and it's ready for weldup. Got some ally tube on order for comp outlet to plenum coming. Need to order another fffffflange for the compressor inlet to get the HSR mounted

-

-

Thinking 10 days off I'm going to get so much done! Nope. Not when you have to keep a child entertained. Didn't get much done today but a little bit further than yesterday. Showing my wastegate position.

-

Looks like I have 10 days off work after the little one has brought Covid into the house. Managed to get my dad to collect some tools, the pipe, bends and my mask from work. Won't be able to use the pipe bender to get that nice curve I wanted. New bottle of Gas delivered thanks to @davecara. Make a start tacking up the side pipe to get an angle.

-

Instead of pie cutting the slight angle on the pipe I will use the hydraulic pipe bender to get a nice curve. Pics to follow

-

The finish on the plasma is a bit rough to be honest as it's just setup to cut dirty big bits of steel for work, I didn't have the plasma cut the bolt holes out for this reason. Quick clean up with a soft pad and drilled the holes. By this time I was getting booted out the door as its a weekend n all.. Have a final clean up before fitting.

-

https://youtube.com/shorts/njVmXx-6bCs?feature=share

-

I have decided to remake the exhaust side pipe to the turbo as the one I have had the wrong turbo flange and it doesn't fit for where I need the turbo, plus I want to relocate the wastegate position. I will upgrade the pipe to SCH10 316 I liberated some pipe from the yard and bought 3 90s on the work account. A wizard in the office gave up an hour of his time on Saturday to draw me up some new flanges on CAD so I could run them on the plasma cutter using 10mm stainless plate.

-

The plenum and turbo was from a bandit setup hence the mods. It went 9 second quarter in its old trim so it's got plenty of poke.

-

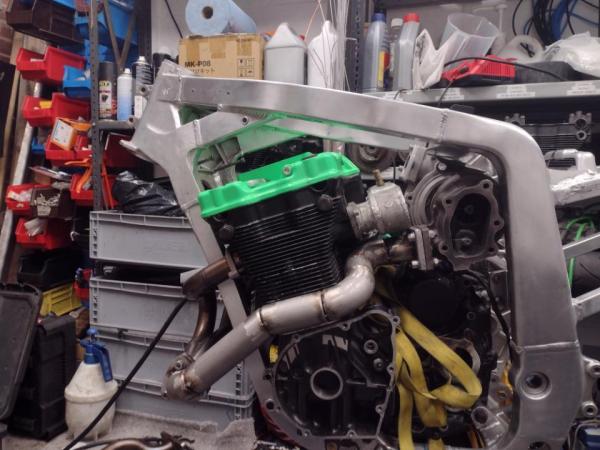

Did a 500 mile round trip to collect the other half of the turbo kit, a carbon sealed Garrett gt28 with a billet wheel, plenum, carb mount and fuel pump bits. Threw it all on tonight and nothing really lines up, it's close and nothing that cannot be sorted. The exhaust link pipe needs lengthening a few mil, shifting over a few mil and a new flange welding on. The plenum intake needs cutting and remaking and a chop cut stick of the turbo inlet to carb mount. Good start though

-

@davecarakindly picked up the cylinder head up last night to have it cleaned and hopefully it will come out good enough to use.