-

Posts

5,418 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Posts posted by Gixer1460

-

-

Different CDI and Ignition switch.

-

Not a fan! Lot of pipe will lose heat energy = less to spin turbo. Look like std. dia. pipe? Smaller than usual helps gas speed. You asked! LOL

-

2

2

-

-

41 minutes ago, skelly said:

Interesting.

How do you go about removing the weld if you need to strip the shaft ?

Do you chamfer the gear bore and shaft for a weld prep before you fit it back on or just carefully tig it as is ?

I would have thought a couple of tacks back and front would suffice - its the friction fit that stops it going anywhere. A cold chisel would break the tacks if ever needed?

-

1

1

-

-

Garrett GT2560R will do a bit more than that but less boost = cooler charge!

-

-

Best start learning or get used to being raped at a stealer! Get a Haynes manual, read it and read it again then try and follow the fault finding diagnosis but if you haven't got at least a good basic toolkit you will be stuffed to fix things but may at least be able to point to the problem at a stealers!

-

I've got an 1100 K/L CDI that I took off when I installed a Dyna 2000 when they first came out. Make me an offer? ( comes with plugs and short cut wires)

-

On 9/12/2016 at 4:59 PM, Duckndive said:

Some of the Silly BHP Jap Car guys spray nitrous across the intercooler ......

Waste of good nitrous IMHO....

Nuffin' to say you can't spray it over the core inside the cooler! Or does that have a downside?

-

1

1

-

-

It'll take a fair bit of force but no reason damage WILL occur........it MIGHT, but that's the risk. Usually 2nd is as worn as 5th so usually get replaced together!

-

1 hour ago, wombat258 said:

I respect your opinion but it is well documented that lower AFR reduces octane demand of turbocharged engines. It does not overheat the turbine. I have raced at 11.9 AFR with no det or overheating and the engine and turbo look great. My race car has serious aero and fully loads the engine on race tracks for extended times. But hey, if you believe in your theory stick with it. If you want to go serious boost though, or have an inefficient turbo with no intercooler, you will have to use high octane race fuel. I am happy at 270hp so no need for high boost and the headaches that go with it.

Its not theory - its tested 369hp with some to go - it only stopped as the undersized injectors max'd out! You are, lower CR, lower boost, lower octane, lower lambda and lower power. If it suits your application then go with it - i'm not knocking it but if a cut needs stitches, a plaster ain't going to be sufficient!

Mine was built to make power, turbo flow is good for potential 450hp , 8 injectors (now with 75% more flow) and an intercooler. If increased AFR's are the cure, why use E85 or Methanol - both have considerably less power potential than petrol even when run rich - its because the octane rating / anti det. properties knock petrol out of the field and you can run as much boost as the engine can tolerate to make power.

-

1

1

-

-

1 hour ago, Danm54 said:

What sort of afr range so I be aiming for then, is 12.1 ok for higher throttle openings and rpm?

For me with the level of boost you are aiming, at it will be sufficient with another point down if things get a bit marginal, some may disagree.

-

8 hours ago, wombat258 said:

I run 9:1 on 11psi, with 98RON fuel. Target AFR is 11.9 at full boost. Higher boost requires lower AFR. Timing should not be over 28 degrees.

Generally agree with that apart from 'higher boost requires lower AFR' It doesn't and in fact it can make the situation worse. You are pumping fuel in hoping it will cool the cylinder and prevent detonation but most will be ejected and end up burning in the turbo which in extreme cases take all the tips / edges off the turbine wheel. The only safe way to run big boost is either lower compression or better fuel - end of! My bike got mapped to 1 bar using regular 98 unleaded but to go higher we used 120 octane leaded race fuel - ign. timing was unchanged, CR stayed 9.5:1, AFR remained stable and fueling adjusted against boost via MAP sensor but no detonation. It hurts paying for that fuel, but power costs and how much can you afford?

-

9 hours ago, Danm54 said:

Its target lambda was 8.5 when it came back from John and it achieved that with a lot of correction. During the last dyno setup correction was turned off and the fuel map was even richer so it was pulled back but it was still richer than the 8.5 target it started with. Think he aimed for 8.2 lambda or 12. something afr.

Nowt wrong there although just using / aiming for AFR of 12:1 across the map isn't necessarily a good thing either.

Comp ratio is 9.1:1 with 12psi.

Again more than low enough - i've got 9.5:1 in the big motor that goes 2 bar +

Pistons are mtc turbo, dished and prepped by Roger Upperton, rebore and valves/head work also by him. I didn't really question or check anything.

Roger should know better, some of the edges that are left are just too exposed - they get hot - they melt - they smear the bores and then you lose the rings. Sorry on the Busa piston thing but seen it loads of times.

Have checked the bleed valve for the wastegate to see what psi it opens at as it was replaced and set by John, 2 bar didn't open it. Stopped there and had a play, the bolt was tightened right to the ball so it was never going to open.

NOT GOOD! You are aiming for sub 1 bar boost with a gate that will grenade the motor before it opens. Sorry its dyno 101 - you baseline at low boost and increase. If it wasn't popping off at 5 or 6psi .....warning bells should have been sounding - not your fault but operators IMO!

The valves should seat on the outer angle then? These only seat on the middle one.

NO - if its a 3 angle cut (that's what race cuts usually are & what Roger would usually do) there is an outer 30 deg cut, the middle 45 and an inner / throat cut at 60 degrees. the 30 and 60 blend chamber / throat into the seat angle @ 45 deg.

Hope that helps?

-

3

3

-

-

Busa pistons? They need to be preped for turbo use - all those sharp and thin edges have to be removed / smoothed out or you get what you've experienced - sorry! As above re valve seats - the valve should only seat on one angle - the 45 degree one who's width is cut after the other two to get the correct width. Hard lesson unfortunately.

-

O rings may look good but could be leaking but usual suspect is the float valve - replacement time! And that could have been the cause of the rich running condition in your other post - just enough to richen but not flood - now its worse!

-

1

1

-

-

2 hours ago, Reinhoud said:

You can't see on the spark plugs if an engine is tuned right, a lot of people see you can, but my experience is not. I've ridden quite a while with a A/F gauge.

The only proper way to see if it's tuned right is to use an A/F gauge.

But its a bloody good indicator something is amiss somewhere!

AFR Gauge won't differentiate between a duff plug due to over rich mixture / oiled up / ignition problem - its only a diagnostic tool.

-

NO - simple answer. Engine stock or modded? If former why is it rich - if latter it usually should be lean unless someone has played but badly!

-

1

1

-

-

Thinking about things - there is no reason not to use TPS with auto correct to generate your baseline fuel map running NA? The correction numbers should be all over the place till the map gets dialed in. I am aware of people who have autotuned a blown set-up but IMO its too risky especially if boost fueling is on a compensation map as most of those have to be adjusted manually? If the fuel map reverted to RPM / MAP based then you could zero / turn off the compensation map and just rely on one fuel map with auto adjustment.

-

APE used to supply Tsubaki chains - don't know if they still do - good chains, i've never had a problem with them.

-

1

1

-

-

If 'auto mapping' used MAP corrections why are you using TPS for load on a Turbo bike? You must have MAP for turbo use so why not use it? Just reduce the correction limits to something like +15 / -5 so it never pulls too much fuel out and try it again whilst logging?

-

Read an interesting comment elsewhere - all engines produce a small amount of water and a proportion of this will get into the oil. Running the oil sub 100 deg C won't boil off the water so leading to increased contamination. With water cooled engines oil temps aren't usually much more than water temp but I believe oil / air cooled engines have potentially higher running temps as oil doesn't give up its heat to well. I don't think there are too many bikes where the oil does much more than 5-6,000 miles between changes when oil technology allows it to live well beyond 20k miles so a little overheating can be tolerated IMO.

-

I've got some of those and seem to remember they were about 1.2ohm individually? Are yours wired in series as that might explain your figure - but they'll be getting 6-7v only?

-

15 minutes ago, zedhead said:

A professional motorcycle electician told me that the mismatch between a standard ECU and the COPs would result in the COPs burning out after 'a certain amount of time', although that time period was not confirmed as being a matter of minutes, or years... Since then I've heard of lots of people who have simply replaced standard type coils with COP with, seemingly, no apparent issues.

I'm certainly tempted with COPs to give a little more room above the rocker cover for stuff, and to increase air flow over the engine too...

Simple question - would you connect 4 Dyna Blue coils (0.7 ohm) to your standard ECU? Because effectively that is what you are doing with COP's.

Easiest way is just add a Bosch 2 channel Ign. Amplifier between the coils and ECU and it'll be mint! Any other way is underpowered COP's or potentially overheated / fried ECU.

-

1

1

-

-

Can't comment on the 'cheating aspect' - see this years Classic TT for that little nugget! But if the 750 barrel casting is thick enough i'd take the 750 liners out, bore the block and install the 1100 liners to retain all the screw lugs and markings. Obviously the bottom edges get shortened and crankcase needs opening out but it would look externally completely 750 stock! I remember Sean @ Big CC did a parts bin hybrid 750 that ended up at 995 - very over square configuration so revved to 13k easily and made good power.

-

2

2

-

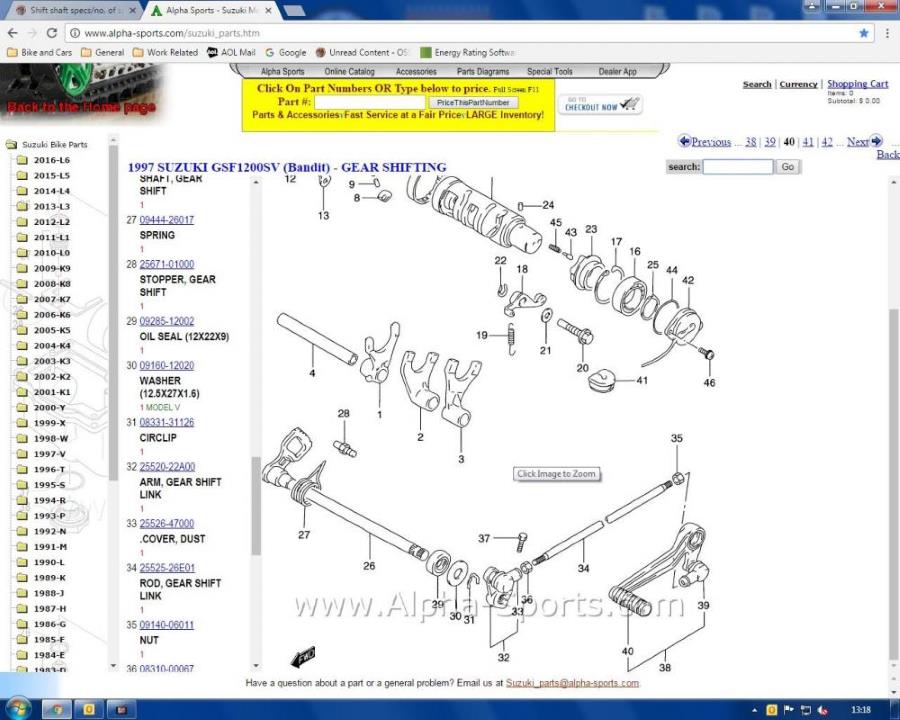

Gsxr to bandit pick ups

in Oil Cooled

Posted

Yes but the CDI's also have different plugs / wiring so can't just plug one to the other! Thought the pick-ups were virtually the same only rotor different?