-

Posts

613 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Posts posted by george 1100

-

-

1 hour ago, rerb said:

Weird, they told me call back if the new ones have the same issue. I'm thinking it's a possible oversight from being designed for the gsxr and something in the bandits head is just a little thicker? Not sure. No spacers, std. Base gasket and head gasket.

Regardless, you should check and make sure as per above post. At the end of the day, there is no benefit in the stud bottoming out, the most important thing is to have the correct thread embedment and enough thread for the nuts. When you look at the upper case, some threads start deeper than others

-

2 hours ago, baldrick said:

so the studs are obviously too short if torqueing them down means not enough thread left up top?

or are you running spacer plates etc?

if not then whats the answer? Maybe threadlock the bottom studs, but dont torquue them, leaving enough thread up top? im asking because i have a set of these to install at some point/#?

I'm running a 2.5mm spacer because of the busa rods but even without a spacer you should check that you don't sink the studs in too far. If they bottom out and you have minimum 10mm of thread for the nut, then you are good to go, if not wind them out and use thread locker. Do not torque the head with dry nuts, use moly.

-

I just made the same mistake by following the APE stud installing method which says the torque the studs into the block meaning they will bottom out which leads to not enough thread for nut to go on. Against my better judgement, I didn't run the washers and ended up with a blown head gasket. Don't go there

-

1

1

-

-

10 hours ago, rerb said:

Dug into it - not the O-rings. I think the copper base gasket started leaking because when I pulled the cylinders, it was stuck to the bottom of the jugs except for one section that was peeled away, exactly where oil was coming from. Probably a fuck-up during install.

Another weird thing: 2 of the APE head nuts rounded off at the stud. Completely lost their thread. Looking at it, it seems that the studs were nowhere tall enough for proper thread depth (only 4 or 5 threads deep in the nut). What gives? did I put them in the wrong location? I ordered a new set of studs and nuts. I know OEM studs have 3 sizes, but the APE ones seem to all be the same. If the new ones have the same issue, can I forgo the copper washer under the nut for more threads?

And finally, I had O-rings over 2 studs under the cylinders, but looking at suzukipartshouse diagrams, I don't see any listed. Does the base gasket not have o-rings over the front corner cylinder studs?

Thanks.

Do you have a spacer plate under the block?

As far as the studs go, you need to have at least 10mm of thread on the studs once everything is assembled including washers. A 10mm stud into an aluminium thread needs minimum 20mm embedment and a 10mm nut needs minimum 10mm of thread as a rule. I recently reassembled my motor and set the studs with Loctite at the exact height first then installed my spacer and base gasket with copper spray. You can measure the stud height by dummy assembling everything or by measuring you base gasket, cylinder spacer if you have one, cylinder, head gasket, head, washers and adding all that together. Use new washers and when you torque the head, put moly on the thread and on the underside of the nut. Torque to APE specs.

Maybe the o-rings blew out due to excessive blow by? Just a thought, I'm not a turbo expert

-

No, head needs to come off

-

1

1

-

-

It looks like detonation

-

Exactly, motors are flogged also, may be modded, air-box gone, pipe change, even fuel has changed, some have lightened their bikes, combine with flogged carbs, it's no wonder so many people are having tuning issues.

-

Take a look at the amount of posts on here and all other oil cooled related platforms and every second post is CV carb related running issues. There's your answer

-

15 hours ago, clivegto said:

Not in my experience and I have built 3 now. 1 with b12 bottom end and busa mk1 pistons. Other 2 also have B12 bottom ends but with busa con rods mk1 pistons. Busa conrods are longer so used a 2mm base plate on both. One of these motors ended up been 1215.9cc 8.83:1 & the other was 1215.9cc 7.95:1 with my humble calculations

Just for the record,Busa mk1 rods are 119.5, 1127 and bandit rods are 117. Spacer required is 2.5mm

-

7 hours ago, Duckndive said:

B12 Blandit Block is good for 1216......1276 would need new liners

And the cases bored out also

I recently built a 1277 only because I found a super cheap 83mm piston kit but if it wasn't for that I probably wouldn't have gone there as it ends up being quite expensive once the cost of the liners and the machining of the block and cases to fit the liners is taken into account

-

1

1

-

-

Tune it slightly fat, run a curved OEM cooler and head cooler and enjoy it. If it was knocking, you would've noticed. The sound is completely different to rattling flatslides. I had a cbr1000 with and open pipe and sometimes it would knock when I would labour the motor. Could hear it very clearly

-

On 8/13/2022 at 11:44 PM, HWB said:

Has anyone here added a knock sensor to their bike ?

Im thinking of a way to install one on my high comp build. Also wondering how it would cope with the rattling of the flatslides.

Is this even possible to do ? Im not saying i wanr to relay it to the ignition or anything (tho that would be cool) just need it to tell me if knock is occuring.

Flatslides rattle is confusing me and i dont want to damage the newly built motor.

Cheers

How much comp are we talking and type of fuel?

-

36 minutes ago, Joseph said:

@george 1100probably

Probably right! Any idea of cost?

-

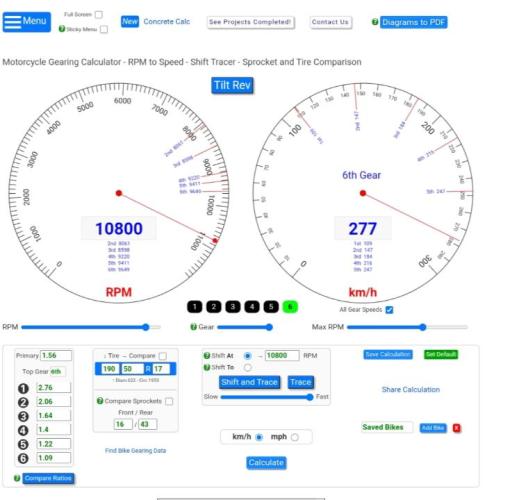

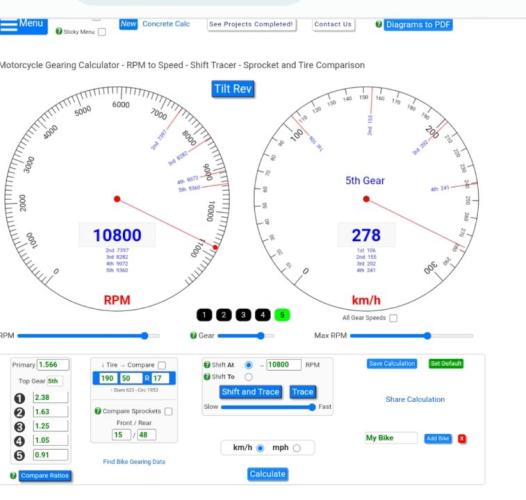

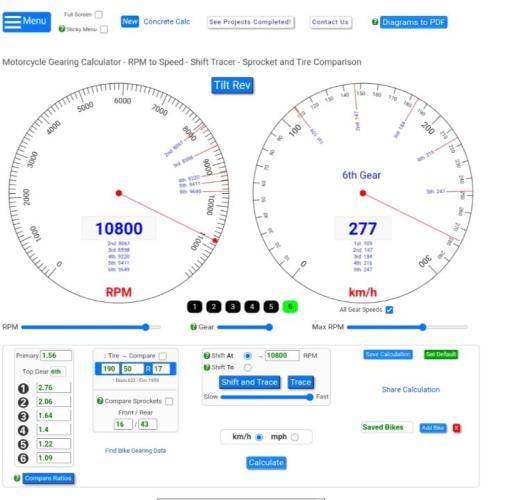

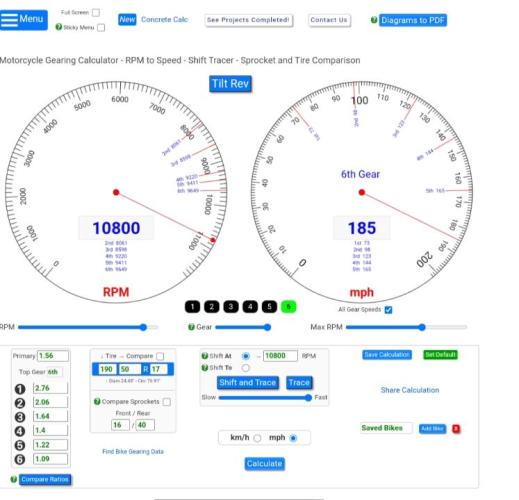

Just for fun, here's a side by side comparison of the 5 speed and 6 speed through the gears. Not so relevant on a street bike but very beneficial on a track bike. Same tyre size and same top speed at 10,8000 in kmh. I can't get my head around mph

. Can clearly see what the motor is doing through the gears

. Can clearly see what the motor is doing through the gears

-

1

1

-

-

-

On 7/27/2022 at 7:00 PM, Joseph said:

At 5000 rpm in top gear, 1127 with 750 6 speed gearing theoretically gives :

15x51 : 192 km/h

15x45 : 216 km/h

16x54 : 205 km/h

16x43 : 257 km/h

At 5000 rpm, stock 1127 stock sprockets

15x48 : 259 km/h

5000rpm?

-

1 hour ago, Oilyspanner said:

Have just done some calculator work, using Joseph's ratios and a tyre circumference of 79 inches.

16:43 final drive gives 1st gear 5.8 mph/1000 rev = 62.64 at 10,800 revs

6th gear 14.68 mph/1000 = 158.54 at 10,800. The speedo would read more than this.

Std 1127r 5th gear is 16.15 mph/1000 revs by comparison.

If you can fit a 17t front sprocket with a 43 rear = 6th 15.59 mph/1000 & 168 mph

1st = 6.15 mph/1000 & 66.51 at rev limiter

It's not worth doing the other ratios as they'll be closer than the std box anyway.

Depends what you want ?

Did you calculate that with a 1.56 primary?

-

-

1 hour ago, Tony Nitrous said:

External oil lines with a feed from the bottom end are quite different from “cam to cam” (which they aren’t) links just across the head.

This or similar was on the old OSS.

https://www.customfighters.com/threads/uk-lees-how-to-make-bandit-gsxr-cam-links.42930/

Should also mention that with the external oiling kit, somewhere in the take off, a jet like the one in the upper case needs to be introduced to limit the amount of oil being pumped up to the valve train which may lead to starving the crank of oil. I've never done it and not sure how people achieve that

-

20 minutes ago, Spirit said:

So all those drag race motors with the three-way setup are wrong? Wow, did not see that coming!

The drag race motors more than likely are using big blocks which cut into the top end oiling gallery hence the external oil line is required to supply oil to the camshafts

-

3

3

-

-

Think of a single lane, 1, that splits into two lanes, 2 and 3. Lane 2, for example, gets blocked but up ahead there's another lane that connects lane 2 and 3 to keep the traffic flowing to lane 2 destination and lane 3 destination. It doesn't provide any 'extra' oiling. It's for show or insurance I guess

-

3 hours ago, Tony Nitrous said:

I’m very envious. I’m not seeing those prices or availability here in Qld, AU.

Yeah, very difficult to find under AUD$1500 these days. They're all hoarded

-

1

1

-

-

One of my previous standard track engines would have around 5 times as much as that after every 3 track days. Every oil change I'd get nervous but it kept going. I keep it as a spare now but haven't got around to stripping it down yet but if I had to guess, I'd say transmission followed by cams and rockers

-

.thumb.jpeg.d4963d0720f7a963b9666513cc38a4ac.jpeg)

blowing o-rings

in Forced Induction

Posted

I used blue. A dab of moly assembly lube on the thread and bottom of the nut. Makes a world of difference. Once torqued, go back the next day a retourque. This give the stud time to stretch. Use a couple of coats of copper spray on the base gasket as a safeguard