Pegleg

-

Posts

394 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Posts posted by Pegleg

-

-

4 minutes ago, Duckndive said:

the pressure at the gate is not necessary actual boost pressure ...

hence you need a reference PSI signal from the plenum ..

and be very wary off a EG a 6 psi spring being a 6 psi spring ...its best to actual check the spring does lift at the stated PSI..

your gate may well be opening under boost "but the PSI" thats making it open may well be a lot higher than the spring,s rating....

Gets coat and goes back to the wake i,m at

Aha. Now I get it. Doh! Thanks for clearing that up @Duckndive

Enjoy the wake.

-

2 hours ago, IhmeJanneFIN said:

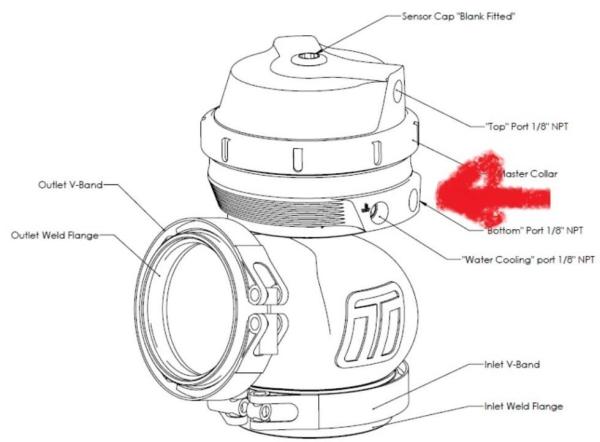

I have a "Turbosmart style" external wastegate, and it has 2 ports above diaphragm and 2 below diaphragm and also have 2 plugs and 2 nipples.

What those are, are different positions to actuate the diaphragm, ie. if one port has an obstruction in front the port and you cannot put a hose to it, so you can plug it and instead use the other port.

The one below is where you should put the boost reference and the above nipple is vented to atmosphere to allow the diaphragm to move.

If you have ie. an electronic 3-port boost controller (and efi), the you would put a hose also to the nipple above the diaphragm as is instructed on the 3-port valve diagram.

Can't understand why I don't have a boost reference. I assumed the spring controlled the boost as you can get different rated springs.

-

21 minutes ago, Duckndive said:

I don't have any boost reference pipes connected. I did have with old internal gate flap set up. I need to look into this further. It definitely lifts off at max boost. Thanks chaps.

-

1

1

-

-

1 minute ago, Pegleg said:

So boost doesn't lift the diaphragm against the spring in the waste gate?

See reply to @Duckndiveabove.

-

3 hours ago, Duckndive said:

It must be connected in some way to actuate it

So boost doesn't lift the diaphragm against the spring in the waste gate?

-

4 hours ago, DAZ said:

The mind boggles.....

-

1

1

-

-

I've got 2 nipples and 2 plugs in the box.

-

6 hours ago, Wee Man said:

Have you got any of the ports connected to anything?

No bud. As it came fitted. Just wanted to be sure it was right.

-

1 hour ago, R1guy said:

How’s the clutch enjoying those dyno figures?

No problems, up to now at least. I'm sure it'll rear it's ugly head.

-

-

-

-

I can bring the Blandit turdo or the CB1157 or both.

-

4 minutes ago, clivegto said:

That's pretty good, what's the power curve like ? what was the fuel starvation symptom ?

That was a quick run up for my benefit. I'll get a better idea when I collect it. Turns out it was "mega rich".

-

2

2

-

-

@clivegtoNot too shoddy.

-

6

6

-

-

-

Also finding room for an unrestrictive fuel filter is a challenge.

-

58 minutes ago, Gixer1460 said:

I have no particular preference as if I have a two outlet tap and only one line to carbs, I just block the spare or convert carbs to have two separate feeds.

If you are handy with tools, a tank adapter block and an in-line, ball valve tap could save a chunk of money?

I've made an adapter with a 10mm push on fitting. The only inline ball valve taps I can find only have a 6mm bore. They're also quite a big lump to find space for.

-

On 10/14/2023 at 1:26 PM, Gixer1460 said:

Really, the 'prime' position isn't meant for running the engine although people do - its purpose / action is, to lift the diaphragm marginally to fill the float bowls on empty carbs - after a rebuild or after running out of fuel. The gap isn't designed for long term, full power fuel flow! Adding a fuel pump would mask a problem, not improve it as the pump will try to draw more fuel than the tap can deliver in 'prime' position.

A Pingle tap (for instance) has a single in-tank delivery pipe with a 6mm bore - doesn't make any difference if tap has 1, 2 or 3 outlets - it has one 6mm bore pipe from tank . . . . and that is enough for over 350+ turbo EFI hp ! The float valves in the carbs, at the needle valve, have a 1.5mm ? opening which across 4 carbs = 28.26 sq mm (approx) and a Pingle has a pipe bore area of 113.04 sq mm. Your 10mm tank outlet has an area of 314 sq mm.

So, the tank outlet is 11 times larger than the carbs can utilise, but its size reduces the potential flow restriction and increasing the pressure seen at the float jets - its a miniscule increase but maybe enough to tip over the edge?

@Gixer1460Any particular Pingel you recommend? Decided to bite the bullet and spend the money.

-

2 hours ago, wombat258 said:

No. If the floats were doing their job you could have a 3" diameter pipe feeding it without it flooding, with the fuel pump turned off. One advantage of the vacuum operated tap is that it shuts off fuel flow to the floats while the engine is not running.

Surely the weight of fuel would over come the floats? Trying to eliminate a fuel starvation issue. Vacuum tap would be great if it flowed enough.

-

3 hours ago, Reinhoud said:

Your carburetors are faulty, the float needles should seal off the fuel supply.

As @Gixer1460said above. I have dramatically increased the flow which might be overwhelming the needles. They didn't flood with an 8mm fitting.

-

On 10/14/2023 at 1:26 PM, Gixer1460 said:

Really, the 'prime' position isn't meant for running the engine although people do - its purpose / action is, to lift the diaphragm marginally to fill the float bowls on empty carbs - after a rebuild or after running out of fuel. The gap isn't designed for long term, full power fuel flow! Adding a fuel pump would mask a problem, not improve it as the pump will try to draw more fuel than the tap can deliver in 'prime' position.

A Pingle tap (for instance) has a single in-tank delivery pipe with a 6mm bore - doesn't make any difference if tap has 1, 2 or 3 outlets - it has one 6mm bore pipe from tank . . . . and that is enough for over 350+ turbo EFI hp ! The float valves in the carbs, at the needle valve, have a 1.5mm ? opening which across 4 carbs = 28.26 sq mm (approx) and a Pingle has a pipe bore area of 113.04 sq mm. Your 10mm tank outlet has an area of 314 sq mm.

So, the tank outlet is 11 times larger than the carbs can utilise, but its size reduces the potential flow restriction and increasing the pressure seen at the float jets - its a miniscule increase but maybe enough to tip over the edge?

That all makes perfect sense @Gixer1460 I'm gonna try the 8mm fitting I had fitted before. Might even experiment with flow rates. See what difference is.

-

14 hours ago, wombat258 said:

Check carb float needles and the seat o-rings for leakage. With pump off they should not leak with normal head of fuel.

They havn't leaked once since I started putting the bike together Months ago. I've done several carb rebuilds now. Seems strange they suddenly leak after getting stronger fuel supply. I will strip them again. Might have got a bit of swarf through when I fitted the bigger outlet.

-

21 minutes ago, imago said:

It's possible that you've found the issue. If the in line pump is letting fuel through when it's off then it's unlikely to be able to shift sufficient volume when it's running.

Ah. I'll test it with a full tank when I've fitted a tap.

-

1

1

-

Turbosmart wastegate.

in Forced Induction

Posted

Decided to fit a boost guage with a recall feature. Will give it a good spank on the dual carriageway and see what it's making. If it's close to 10psi I think that's about right. Not a race bike, just something I've always wanted to build.

Gotta build my kid brother one now coz its more powerful than his H2.