-

Posts

202 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by peter1127

-

In my experience dynojet kits are not an instant improvement especially when intake/exhaust stuff is not stock. I would let your local dyno specialist jet it properly. No point in tuning a bike that needs maintenance so make sure carbs are in good order (needle/seats ok, fuel level ok, replaceworn out emulsion tubes, no air leaks anywhere) and at a minimum airfilters are clean. Best to do all the relevant maintenance as well : plugs, carb sync, valve clearances. A dynokit doesnt add anything at WOT over a properly tuned bike. It doesnt improve airflow into the combustion chamber so it cant improve performance. If it adds, it just means AFR was off before. It could improve throttle response because of the soft spring, drilled holes and needles to match. But that improvement when going trough the gears is exaggerated on a dyno because of the much faster increase in rpm then what happens on the road. If you want less loss with gear changes just fit a quickshifter.

-

my 5 cents: used castrol full synthetic 10W60 before on a gsxr bigbore. Fairly high sudden oilconsumption and slipping clutch. It wasnt strictly speaking motorcycle oil so there is that. I use castrol halfsynthetic RS 10W40 ever since without issues including gsxr1000, hayabusa,modern gsxr750, a high compression bigbore and a 340HP turbo. I change it every winter which for me means 2000km. (the turbo bike every 1000km or every year whichever comes first, including a good check on shiny debris:-) Any halfsynthetic 4stroke motorcycle oil from a proper brand would be fine I imagine, I'm just used to this stuff. Thing is with full synthetic, they can dissolve gunk which was building up inside your old knackered engine causing issues, especially higher oil comsumption. On a fine rebuild engine I would expect no problems except possibly clutch which can be circumvented. (of course dont use full synthetic to run in new pistons) Personally I would stay away from all kind of special so called high performance racing oils if they are not for 4stroke motorcycles and not for road use. Some of them degrade quickly since they are made for short high performance and not for longevity.

-

Ordered the MTC pistons. Will see how much I can safely cut out to lower compression. thanks guys

-

MTC seems good option, not sure how I missed that :-) Yes I could probably machine a dish and add a 1mm(?) spacerplate

-

having trouble finding pistons with low CR for turbocharged GSXR1127. Looking for 8:1 maybe 8.5:1 compression and 81mm/1216cc. All pistons I can find are high compression so need a crazy spacerplate to lower compression and squish is gone. Anybody a recommendation?

-

Indeed DJ kits are not helping. Part of the kit is drilling larger holes in the slides and softer springs so they go open earlier/faster. I had problems with that in my previous carbed turbo setup: always got rich stumbles the moment boost came on. Replaced the needles, slides and springs with stock ones and behaviour was good. If the carbs are modified well, jetting and needles are close to stock. That also makes the AFR not sensitive to variation in boost level. I had 340rwhp with stock 125mains running nicely at WOT with 11.5:1 AFR and still have good off-boost behavior and decent fuel consumption when driving normally. Key was having pitot tubes facing the middle of the airstream going towards the bowls. (I had 40mm original carbs, 2 pitottubes each going to the stock bowl T connection, pitottube 8mm which is 6mm bore size and 2" uppipe that contains the pitot tubes. Dont connect anything else to those pitot tubes as it messes with the function. No additional T's, nothing. Its sensitive)

-

yeah making a loom is a lot of work. Pays off to start from scratch!

-

Im working on a 100% road bike which will also be used for something other then straights.I added a hayabusa swingarm and made that longer.The bike is 100mm over stock. (89 gsxr1100) Feels still fine at roundabouts and stuff. Of course never so nimble as a modern 1000. Im in the process of tuning the bike, let you know how it feels under boost.

-

ah good! What did you do to fix it?

-

GSXR1127 1992 model with 40mm carbs

-

Hmm weird behavior. Basically not closer to a solution. Possible issues are: AF wrong (jetting) fuel issue (fuel supply) slide issue BOV issue Ignition issue Maybe you can do some tests to exclude stuff: O2 sensor should be wideband. If not, its not so useful. Also rich stumbles often dont show. Dyno run including shifts with proper sensor might reveil something When the issue appears, shut the bike down including fuel pump and check bowl level. If almost empty its clear where to look. check with gopro the slide behavior (which with a plenum is troublesome, maybe it fits and add a light;-) Slightly more spring on the BOV so you are sure it doesnt open a bit when boost starts to build. Change plug, smaller gap. Check/replace coil & wire/cap

-

What I did is have the pitot to the bowls only, and BOV/FPR on carb connector.

-

If you hold the throttle and it builds boost, but after 5-10secs it gives up, I suspect this to be a fuelling issue. If there would be a slide or BOV issue, it would have that problem immediately once boost builds, not with a delay. If too rich after 5-10 sec I suspect too high fuel pressure or the floats cant hold the pressure. Plug should indicated this. If too lean it could be not enough fuel flow causing empty bowl. Clogged needle seat, failing fuel pump, clogged fuel filter, kinked hose, clogged fuel cap vent, vacuum operated tap closes? Other thought: you make more boost so ignition fails. Replace plug and reduce gap.

-

If you lose boost due to the BOV opening when it shouldnt, that is different issue than the slide closing once you achieve boost. Not sure how a lost vacuum opens a BOV valve? Lost vacuum means there is more pressure, exactly what you want to keep a BOV closed.

-

If I translate "messing" into "influence", then yes, could be if this is used for membrane pressure. The position of the cv slide is a balance between: pressure above the membrane solely caused by existing hole(s) in the slides: a result of plenum pressure and venturi effect reducing that pressure. pressure below the membrane which is plenum or pitot pressure depending on chosen solution. If there is no connection to boost, or there is a hole/leakage towards ambient, the slide will close once some boost occurs simply because pressure above membrane is higher then under membrane. Spring. Can be played with in combination with needles to finetune offboost/cruise behavior. Its also worth checking the membrane for rupture and sealing around the edge. Often overlooked. Using pitot connection also for "under membrane" pressure is imho not needed. This pitot solution is mainly beneficial for bowl pressure and if done correctly the main jet is close to stock which makes it easy to deal with different boost levels. Still, its very possible that this is all due to a very low capacity engine having trouble spooling up the turbo.

-

What you describe might just be turbo lag: 200 cc is not much to get a turbo to spool up and no boost at cruising at low speeds/rpm is normal. Then when you open the throttle I expect a delay which can be massive at lower rpms. Cruising at higher speeds/rpm you will see a little boost and when opening the throttle that should raise fairly quick. Anyway for your carb try this for information https://oldskoolsuzuki.info/?s=carb+turbo Summary: make sure bowls dont overflow, seals, needles and seats must be MINT. Might need to lower fuel level a bit Fuel pressure need to be 1:1 in relation to boost, and only a couple of psi above boost otherwise you have a shower head Pitot out of middle of airstream to the bowls Below the membrane you need pressure. Depends on your carbs how to do that. Maybe you already have that, if not you could drill from plenum side towards under the membrane. If not possible a dedicated line. I dont expect it makes much difference if that is from a pitot or not. Above the membrane all is well: the existing holes take care of that. Plastic caps might crack, alu is better you might need weird needle settings or even custom shaped needles. Depends on all kinds of stuff: getting off boost and cruising ok is the hardest part in my experience. Can play with springs too Check you enrichment system, plungers can be pushed out under boost messing stuff up

-

Indeed face into the airstream, as close to the middle as possible. I made 2, each for each pair of carbs. Worked for me in a way that main jets were very close to stock, which means if boost varies AF is still ok.

-

vacuumtap wouldnt work: it closes under boost Diameter of fuel tap doesnt matter in static situation. Only the height difference between top of fuel and bowls result in pressure. Needles & seats need to be in perfect condition on a turbo bike to deal with the fuel pump pressure anyway. Best open it up and check, and replace when in doubt. Could also be debris which entered the system when working on the fuel system, or a ruptured filter.

-

Bought the scavenge bit from Tomaz too 2 weeks ago, just got delivered. Looks and fits good, didnt run it yet. I understood he had health issues compromising delivery this summer. Cant speak for other cases but he responded me swiftly on messenger and I got my stuff quickly.

-

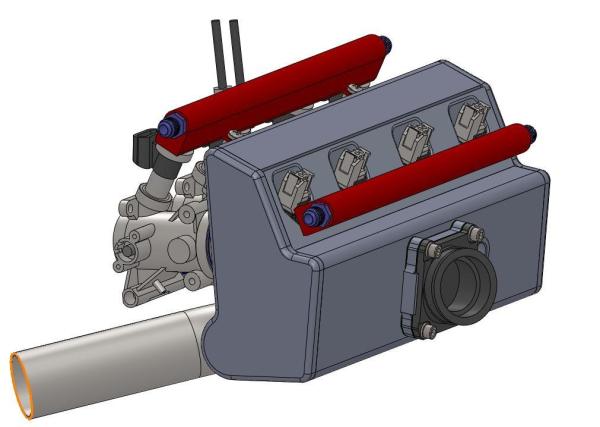

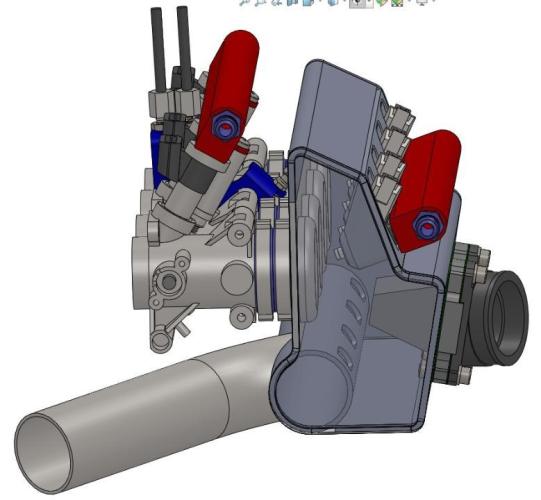

yeah I gave up on it. Good points all around: its hardly worth the trouble and might be unpredictable, pita to get right and even when its right it eats turbo's. Just doing what always works: as large engine capacity as possible, dont lower CR too much and get tuning perfect in off boost situations. But the reed valve idea I like, I also saw this in the "show us your plenum" thread. So decided to add that. Found something of a KTM SX2016 including air intake that ofcourse also will have a filter. Also made a chamber that should even things out.

-

Reed valve interesting thought

-

I guess I shouldnt ask.

-

Well, shifts are not really an issue unless looking for the last tenth on the track. Its about normal driving on the road: closing the throttle before the corner,and opening it at the apex. Then there is a second of nothing followed by a power surge. I would like for that to be smoother, hence I'm looking for options like this anti lag valve.

-

In rallysport they indeed add fuel and ignite it before the turbine: spectaculair and effective, but it eats turbos. This is supposed to add air to burning gasses in exhaust caused by excessive retarded ignition. So it must have a very lean combustion which will indeed be very hot. But as opposed to the rally version I assume the amount is much lower, so it would be less damaging but also less functional. On the road its main advantage would be reopening the throttle and have some boost already available or at least quicker available. I'm not looking for launch control.