-

Posts

95 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by Baron

-

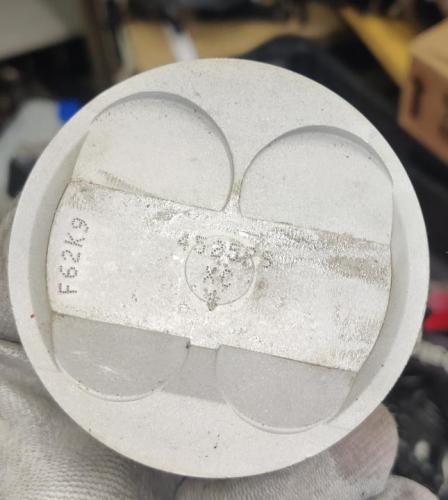

Time to finally continue this project. I stripped whole bike down into pieces and sent our for powder coating. Next thing was to design some kind of instrument cluster mount since everything was used to be just "hanging" there. Mount is 3D printed with ABS and mounted on handebars. Current state: I have a problem with extented swingarm which I bought as second hand. I was told that it was used in GSXR 1100. It mounted fine into the frame but problem is with rear axle and wheel. With stock swingarm, distance between swingarm holes is 245mm and on extended swingarm this same distance is 240mm, so whole package with wheel, spacers, etc wont fit in. I also tried to spread the "legs" apart, but it only gave 3mm extra, which is not enough. One solution would be to grind some meat off from rear brake caliper spacer and hanger itself, or use something different kind of chain adjusters. Any idea how to fix this? Also need some part sourcing help. Here is picture of "older style wiseco piston" which I bought as complete set as second hand. Can anyone confirm this by the marking? Where would I find suitable piston ring set? If I go with busa gen 1 rods, where should I buy them from? Thanks for checking out!

-

I just cut flat spot to the plastic washers with side cutters. Works like a charm.

-

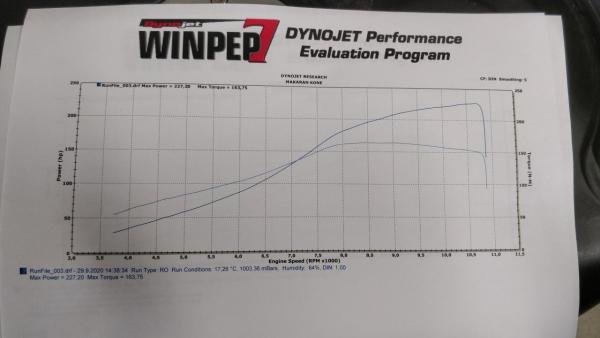

Now it's time to continue this project to step 2, big bore and more boost! Plan it to increase boost to 1.2 ish and also of course build the engine to withstand those numbers. I want to keep project costs relatively low, so no carillo rods, etc. There is a couple of things to think of: - This engine is 1991 so it has shim head. I have read that many people have changed their own ones for screw head, but newer told the real reason. Is there a real risk to increase boost wish current head? - Oil cooler placement - What rods to use, Maxspeeding water cooled? Will they clear the crankcase? - Sourcing for intercooler. I have been 2 days searching online for matching size one with outlets downwards, but couldn't find. Maybe open thread on wanted section? - Sourcing for bst40 aluminium carb tops. - Dyna 2000... Or is there better ignition control units? Not going for EFI at this stage. - I have blown R750 short stroke dot engine with OK condition cams in it. Should I swap those cams? What I already have on shelf: Used old style wiseco low comp pistons with corresponding bored block. Piston tops are soda blasted and will need all new rings. Working old green dyla coils.

-

I have put 1100 teapot engine into 750K frame without taking anything off. It is tight, but can be done. You have to play with lower back engine mount. Either make spacer which you slide into engine or drill mounting holes on the frame to 12mm. Once engine is in place, only way to remove valve cover is to take all engine mounting bolts off. That way engine drops a few cm and you are able to take cover off. So protip, adjust your valve clearances before mounting the engine.

-

Save yourself from pain and use 4 pots

-

Welcome!

-

Are those alutops for 40mm carbs? Where did you find them?

-

Yeah, 0.7 bar boost. Haven't made changes on jettings, so still running with stocks.

-

-

Finally had time to install PLX wideband. Summary: 20-60km/h: afr 16 90-110km/h: afr 14.7 Full throttle: afr 11 Adjusted mixture screws by those results which are 3 full turns out now, so theres a need for bigger pilot jets. Full throttle afr is concerning rich. Current main jets are 125, maybe go for a size smaller? Found a local supplier for lock-ups. Also installed new OEM full clutch pack. No more slipping

-

I'm using castrol power 1 10W-40 semi synth oil. Who is the "best" supplier for lock-up clutches and also delivers to Finland? 0.7 bar boost is the lowest that turbo bypass can go. I've adjusted bypass actuator rod as long as it can be.

-

So bike is GSX-R 1100M. Got it pretty cheap and only problem was that it wasn't running at all. After cleaning carbs, replacing gaskets, new spark plugs and filled it with new gas got it running pretty well. Transmission works perfectly and overall engine condition seems very good. Then started to make some electrical and bodywork modifications. And of course slam it with turbo. After making a few new exhaust bolt threads got the new manifold mounted. Exhaust manifold is from ProBoost and turbo is modified TD05-16G. As for carb modifications, blocked stock diaphragm venting hoses with aluminium pieces and glue. Installed and glued new metal T-pieces for fuel bowl venting. Also drilled new 5mm diaphragm venting holes to plenum side. Jetting is stock. Couldn't fit stock oil cooler so I bought universal chinese oil cooler with AN8 fittings and made new oil lines with Torques couplings and adapters. Cooler is mounted at the bottom with stock rubber mounts and also I put OEM style round dampeners on top. Next step was to fabricate mounting plate for fuel system components. Fuel pump: PIERBURG 7.21440.78.0 Filter: WIX WF8033 Fuel regulator: Malpassi Bracket was mounted at the old airbox location. Next step was to fabricate exhaust, electricals and new tail fairings. Also made case for fuel pressure gauge and installed it. Tail fairing is from Kawasaki ZX-6R 03/04. Got it all assembled and fired up. Had some problems with idle and after boost rpm fluctuation but that was fixed with rising fuel pressure (0.15bar at idle). Current state: Because everything is stock i'm running with 0.7bar boost. In there future i'm going to rebuild that engine to withstand more boost. TODO next: - Install some kind of oil catch can. I'm getting pretty much oil out from those small filters, especially one which is mounted on oil fill plug. Advices? - Clutch started slipping... Which brand clutch should I buy? Maybe go for lock-up also? Thank you for your interest!

-

Thanks for your replies! I raised fuel pressure to 0.15bar and that seemed to fix this fluctuation problem. I just received my plx afr gauge and will install it next.

-

I have a couple of years experience with building and tuning N/A oilburners and now I made my first FI bike. Setup Bike: 1100 GSXR 1991 Fuel pump: PIERBURG 7.21440.78.0 Filter: WIX WF8033 Turbo: TD05-16G Carbs: Stock 40mm - Drilled 5mm holes from carb intake to under diaphragm - Blocked stock breather hoses with glue and aluminium pieces - Vent bowl breathers connected into pitot tube located on charge pipe - Jetting: stock 125 main jets, stock (14.6mm) fuel level, needle on third (middle) slot, mixture screw 2 turns out. Fuel regulator: Malpassi Gauges: fuel pressure, boost pressure, (PLX AFR will come also, delivery problems...) Ignition system stock for now. Atm plan is to run with mild under 0.7bar boost. After very short ride it will hit 0.5bar boost without problems. Question 1: Problem is that revs will hang after hitting boost and pull clutch. Also revving on idle will cause rpm fluctuation and slowly dropping. Just try to play with mixture screws or is there anything else? - Renewed intake boots and o-rings. All hose clamps are tight. Tried to spray carb cleaner into rubbers, etc, no change. Question 2: What should be fuel pressure on atmosphere/idle? Currently it is 0.1bar. Is there anything else to consider?

-

I have problem of choosing which bike I start to modify. Idea atm is to install turbo on it and drive with mild boost <0.7. Later build big bore engine and hit some more boost. What bikes I have: 1. White 7/11, so K 750 frame and powerscreen engine with stock 34 bst carbs and V&H exhaust. 2. Black stock M 1100. Stock 40mm bst carbs and all. 3. K 750 frame. Had blown engine, got all parts to build complete bike. And what else parts I got laying: - 115 000km driven 1127 powerscreen engine, working well. - Older (1193) wiseco piston kit with bored cylinder. For NA use. - Older (1193 or 1216) wiseco lower comp piston kit with bored cylinder. For turbo use. - Carbs on shelf: RS34, bst36 (K750), bst38 (M750), bst34 (1127 powerscreen), bs34ss (GS1100G been on turbo use). - Turbo parts: plenum, exhaust manifold, fuel regulator... Soon going to oder also td05 turbo and other necessary parts. Which one would be easiest to start with?

-

Sorry for being curious but how can u blow up oil cooled engine?