Buzuki

Members-

Posts

180 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by Buzuki

-

- Any mixing of low pressure cyl.head oil cooling system with high pressure lubrication system is Wrong , at least from simple reason that oil from cyl.head oil cooling loop is Not filtered , so any dirt or small metal pieces can unrestricted to reach both cams lobes and cams journals and can cause serious damage . - IMO best way to achieve filtered full oil supply to cams and rocker arms is to have one separate external oil line per each side of engine , which connects crankshaft main oil gallery to cyl.head four side bolts , but there man have to be careful when choosing internal diameter of these oil lines (pipes) , to big internal diameter will cause reduced oil pressure on crank shaft bearings, any way after this mod measuring for correct oil pressure in the main oil gallery is one very very obligatory and Important step. - just measured holes diameter of two oil jets (14S) which directly determines oil amount for camshafts /rocker arms lubrication on 750R slaby , each oil jet have just four 1mm hole , which IMO pretty much restrict correct oil feed compared just with four rocker arms holes where each hole have 1,4mm dia. intended for beam spraying and lubrication of cam lobes , IMO those restriction oil jets deserve at least one or two more 1mm hole to be drilled to get less oil feed restriction to camshafts/rocker-arms. - IMO by engine assembly special care have to taken to good sealing around oil channel in cyl.block(red arrows) , any internal oil leak in direction to crankshaft can cause reduced amount of already reduced oil feed directed to cyl.head lubrication loop. -btw , just for example very high reving ZXR400L have just one external oil hose dedicated for lubrication of two camshaft and 16 rocker-arms which connect main oil gallery with cyl.head.

-

-

Thanks ! but note that both fuel filter and fuel lines don`t touch hot engine block nowhere .

-

wsn03 No problem with fuel feed at all if the diesel pre filter is instaled under the carbs, btw ,also want to insert one cylindrical small neodimium magnet inside of the fitler on the fuel input side to collect oxidation metal dirt which sometime come from fuel tank , I think that sand like oxidation metal dirt is bad for engine cylinders and piston rings health , that metal dirt can behave like some fine lap paste . (will post few pics later)

-

In my 88-R750J I use just one Bosch Diesel in line fuel filter but positioned under the carbs , Diesel fuel filter can not cause fuel starvation since is not paper based but is plastic fine mesh type, just one rubber pipe comes from fuel tank tap to under to filter , tap second output is closed with one short rubber pipe and one bolt , from filter output I use one plastic T piece to connect to carbs two fuel inputs , by positioning filter under the carbs he also colect water from fuel , water is heavier than gasoline and can not raise in the carbs float bowl chambers , btw ,I have also instaled four small neodimium magnets ( about 4mm dia and about 2mm thick taken from some old PC hard drives), one on each float bowl bottom to collect rusty dust which comes from fuel tank , those small magnets can not move and cause carbs mallfunction since they become magneticaly glued for drain metal bolts . and yes , from my experience carbs fuel overflow is allways caused from bad O rings above needle valves , thats one very very critical point for carbs corect function.

-

DOT head originaly belong for 88/89 (J/K) R750 model , 88 cams have leter B stamped on the side .

-

Also check for static compresion ratio ,first F model was with 9,8:1 but G/H models was with slightly higher 10,6:1 ratio .

-

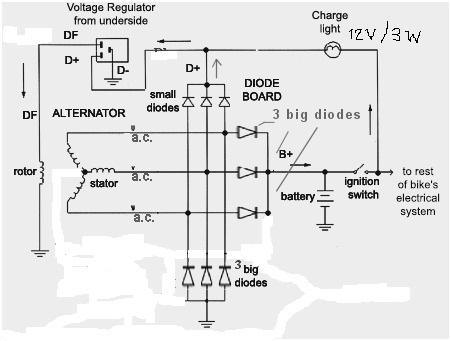

Also want to experiment with Suzuki alternator connection on my oilcooled 750 project where by me alternator internaly will be slightly modified and conected in more conventional way , one more warning red light(12V/3W) will be added on the front small control board , that modified internal connection need three new small diode (1N5408) to be instaled , in these configuration any standard solid state voltage regulator can be used not only original Suzuki , any suggestion ?

-

For carbs deep cleaning I use Trichloroetilen bath , just leave carbs for hour or two fully immersed in that metal bath and after is removed it will be like brand new , inside and outside , after that only compresed air is needed for dryin out , Problem is that Every Plastic or Rubber piece have to be removed from carbs before that very agresive chemical bath or will be totaly Resolved and Destroyed !

-

Have ho experience with Dyna-coils but I will try to explain some fail mechanism and remedies related to ignition coils and other elements inside of the ingnition system on oilcooled Suzuki engines , - When ingnition coil fail ? , usualy when secondary side (HV- high voltage side ) remain and run without of any proper load , than sparks do not discharge HV power on asociated pair of spark plugs but inside of the coil secondary side causing that coil to short and fail - What is the elements and values of that load by Suzuki secondary HV side ? , on the first place spark plugs than spark plugs caps and finaly High Voltage cables - Which elements fails and cause coil to fail ? , usually that is the load or RFI supressor resistor which can be found inside of each spark plug cap , value of that resistor is around 10-14 Kohm, my remedy is to on time change those resistors with plain copper solid piece of wire which have same diameter and lenght as removed resistor , -but wait than coil have no any load/RFI resistor anymore ? , no since inside of each spark plug is inserted or buit in one resistor , for example standard spark plug NGK-JR9C have built in resistor with value of around 4-5 Kohm , that R leter on spark plug body is sign of spark plug with built in resistor , not sign for Racing or something else - about High Voltage cables , standard Suzuki copper wire cable type is excelent ,only problem is that after many decades of use they become hard and not so handy to be removed or inserted , -What is the best and worst alternative ? , good alternative is any quality HV cable copper wire conductor type , bad alternative is any graphite based conductor type -and yes , when all listed elements are OK than standard Suzuki ingition coils is more than adequate , their quality is excelent .

-

-

Yes , thanks !

-

Many thanks for clarification ! , will check everything for sure .

-

Just found something on NET , it`s Ohlins recommendation list catalogue from 2005 , where model SU003 its recomended for GSXR750 88-91 , but model SU527 is for GSXR750 85-87 , still confuse me model SU0031 which is not listed . http://www.stevecramerproducts.com.au/download/r&t2005.pdf but SU805 is listed for TL1000 97-98 model , it`s one very confusing list of numbers .

-

From long time ago was striped from one Suzuki race bike altogether with exaust system and some other things , that 421 exaust system is on my gsxr750j bike now for decades , I believe that this rear shock is actualy good for J/K models same as exaust .

-

Well , right now my head is in engine so I have no full atention on the frame Hole to hole centers spacings is around 314mm

-

Stands by me for years and now I want to use them as rear shock on my slabside 750 project , will fit or not ?

-

Just cross checked in my storage and found no front fender for 1985 model , but I promise you that tomorow will contact few of my friends who still keep many used but OK parts for old skool GSXR bikes , it will be good to post here few pics of that particular 85 front fender , those pics will help me a lot to pick up the original one for you .

-

Also I have one airbox if is needed .

-

I fully respect and understand your intetion to keep that bike in original condition !

-

What I don`t like about original exaust system is that the inner diameter of the exaust four pipes are much smaller than inner diameter of four cyl-head exaust holes , IMO that suppress engine breathing and limit engine to produce full peak power , for low/midrange RPM that mismatch is not so important but for high RPM it is , I think that is the one major place where Suzuki chocked those early GSXR engines to not develop over 100HP , since in early/mid 80` was some sort of` Gentleman agreement ` in beetwen big motorcycle manufacturers to not sold motorbikes with more than 100HP to customers , today that agreement do not exist anymore , to make long story short , when I replaced original exaust system on my 88 gsxr750j with full open race system I have noticed two things , one is that my bike become much faster , and second is that engine developed less heat , less heat indirectly means longer engine life .

-

Hi biild ! I like you bike which is in almost original condition , and I like you idea to restore and keep engine in original condition ,but I think that you don`t need to fully open whole engine since major wear becomes usualy around cylinder block and cylinder head , except in case if you gear box is bad than to fully open engine will be required , any way you can check my topic on similar 750cc bike as your in -OSS members projects- part of the forum , under the topic name - Resurecting old racer - Best Regards

-

Basicaly is allways good to put each part on his previous place but if you allready mixed them... , btw , what is important is to have Perfect sealing on All O-rings , special on those over the needle seats .