All Activity

- Past hour

-

I will see if I can find a diagram. Think I saw someone on here at some point with a set of later gsxr ones fitted to a oil cooled bike ?

-

High pressure is all internal - anything outside is low pressure.

- Today

-

Same thing happened with my dual pipercross filters, I lost one of them the first time I went out with them fitted , had to buy another pair of filters , even though I only needed the one, pipercross wouldn’t sell me just the one like you I’ve got a cable tie wrapped around them now

-

they where the settings the guy on the net used and it ran shit !!!! thats why i used his modified settings, my bike pulls through pretty good but the revs hand in-between gear changes so a lean condition, if i use the dynojet settings it will (in theory) run even leaner !!!! but i suppose its worth trying. one other thing, the fecking K&N filter on 3 and 4 keeps sliding off the carbs !!! ive cleaned everything up and still slides off no matter how tight or loose i have the screw clamps. had to wrap a cable tie round it

-

Upshotknothole started following dynojet settings on B12 and Gsx1250 clocks on to MK2 b12

-

I'm not sure if those 1250s were canbus or not. If it's canbus, they won't work. If they still had a traditional harness and computer, they might work. Try and find a wiring diagram and see what the pin out is to the clocks.

-

2nd from the top. Dynojet counts down from the top in all their instructions.

-

Take it, when you say 2nd clip you are saying from the top grove? Or are you going 2nd grove for the bottom? A numpty question but just want to make sure, as some people go from the top and others from the bottom

-

Scroll down to Downloads, the instructions are in a PDF. https://www.dynojet.com/jet-kit-for-1997-2000-suzuki-bandit-1200-gsf1200-3154/ First gen, with pods and full exhaust... Needle on 2nd clip DJ155 main AF screw 2 turns out. I think most of their kits have similar instructions, because these are really similar to the 750 stage 3 I'm currently setting up.

-

wraith started following Gsx1250 clocks on to MK2 b12

-

-

Joseph started following Turbo return catchtank size

-

I’ve recently set up a stage 3 dynojet kit on my mk1 b12 , I used an air/fuel gauge and a colourtune for setting the pilot screws, 150 dynojet main needle on 2nd position down with the 0.5mm shim, effectively position 2.5 pilots were set individually with colourtune , settings range from 2 to 2 7/8 turns out , so somewhere in the middle should be a decent place to start im running pipercross dual pods, black widow headers , Remus powercone end can

-

just got a dynojet kit stage 3 for the Zed (B12 engine) it came with no settings !!!!! can't find fuck all on their web site ? found a thread on the net and the guy said the base settings he got sent where crap so went with his modified settings, bike is running K&N twin pods, pulls good but rev's hang so running lean. my settings 155 main jet clip on 4th groove down mixture screws 3 1/2 turns out what have you guys set yours too ?

-

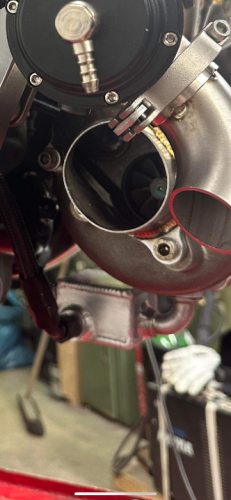

Anyone thats have a idea of size return tank? I have top bike mechanical pump, 1mm restrictor to turbo, but have problems evacuate oil in higher rpms. Currently tank is 55x55x35mm should i build bigger?

-

That does make sense. As it stands it's just going to be a rolling chassis for some time still so i can set it up as planned and gauge what pressure(s) i have. A mate mentioned running the main coolers in a parallel configuration to potentially reduce pressure loss, although that would be at the cost of lower flow ? Might help on the contact time aspect ? Generally speaking are the oil lines going to the head on the high or low pressure circuit ?

-

Of the 'normal' OC engines - GSXR, GSF etc. they have a two part pump, one does the pressurised lubrication system, the other does the cooling circuit. I think the broad range quoted covers both sides as generally they pump multiple gallons of oil per minute such that probably 50% is bled off straight back to the sump via relief valves - the HP side will hit 100psi when cold whilst the cooling side doesn't have much pressure but relies on flow and contact time to carry heat away. Hence my thinking that multiple rads adds resistance to flow which could result in worst cooling but increased capacity. The OC's have fixed gearing unlike the AC bikes - non adjustable - AC variants done mainly for a boost in pressure - 10-12psi std, upto 20-30psi when re-geared. A dry sump system has lots of advantages - massive (comparitively speaking) oil capacity, no oil surge / sloshing in a 4 wheel application, simple pump re-gearing to slow or speed up delivery / pressure, cooling circuit for oil tank can be independent of engine and taken to extremes, the engine can be mounted lower in chassis to improve CoG and handling due to shallow sump! Its always an unknown with engine modification - will it hurt the engine, will it reduce reliability? Sometimes 'over kill' can work against the common good!

-

Found some at bofiracing in uk. £5 each for future reference. Cheers.

- 1 reply

-

- 1

-

-

Damn that is a good point The Manual states that the nominal pressure of the oil system on these lumps should be between 45-85 PSI at 3000 rpm. Weird that there should be such a tolerance gap at a given engine speed ? But thats the figure. Obviously since i literally have no idea what i'm doing, i have no idea how to work out whether thats good enough or not. We have OC bikes on here running aftermarket 19 rows + head coolers, but i guess none with 2 mains + head. Would any (if possible) swapping of oil pump gearing ratio be any good ? Or is it one of those more flow/less pressure things where you basically compromise (didn't i read something about AC GSX750 pump being fitted to AC 1100s for some improvement reason ?) Dry sump is an ideal solution, yep, but thats a whole can of worms and budget i hadn't planned to cover (and currently again have no idea about how and if i can fit it on this). Obviously if the choice is between dry sump or a broken engine, i'll have to sort something out

-

I'd be cautious about adding lots of smaller coolers against one larger one due to possible limitations of oil pump to have pressure capacity to push through multiple restrictive coolers and oil lines connecting them all up? As this is a car application, a 3 port scavenge / pressure pump, dry sump and remote tank would certainly be the best solution - plenty of Hayabusa's using dry sumps!

-

Increasing oil capacity does seem like a good idea. Originally on the bike there is a 13 row oil cooler, I have a 14 row cooler/heater for the head and 2 19 row coolers for the front of the car, so that along with the extra plumbing has tripled the cooling capacity. Not sure whether i can add wings to the sump due to space though, and how much i can pester my mate who welds alloy for me at his job, he's already needed to mod the IC i bought

-

Sweet, thanks.

- Yesterday

-

Used a slide hammer with the 'lip' attachment that threads on the end to do mine. Came out with a couple of pulls...

-

I think that's how the slabby ones come apart. Slingshot ones are cone shaped and the plastic part can only come out after that brass piece is out of the way. No way to get behind there to knock it out without destroying it. Letting it sit in the freezer for a day, tomorrow I'll try again. Thinking maybe after letting it sit in the freezer, a blind bearing puller might work.

-

Considering how expensive my divorce turned out to be, this motorcycle will probably have to change its owner:(

-

From memory, if you remove the guts out from the other side you should be able to get access to tap it out

.thumb.jpg.b88483ea8d5ed881efcaeecb8e56ebd4.jpg)