-

Posts

235 -

Joined

-

Last visited

Reputation

410 ExcellentPersonal Information

-

Location

the netherlands

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

GSXR has a tank vent which is sufficient. If only vent in the cap this might not be. Imo best to check all hose routings/connections for kinks/leaks anyway. We all know the challenge to get it properly and keep it properly. Drive with open cap might prove messy, I would just remove the valve bit in the cap so its for sure unrestricted and try that. With these problems its a process of elimination. Just check all the stuff you can think of and at some point there are not many things left it can be. Since it worked before its not a system design issue. Since it works the first 15km and works again after a short while again that eliminates quite a lot. in order of likelyhood I would say: 1. tank vent 2. hoses kink/leak 3. Fuel filter almost blocked and/or crap in carb bowls 4. Enrichment system problem: plungers are pushed out by boost. But that remains after a short while unless you manually switch off enrichment at that moment 5. battery undervoltage by fuel pump drain/charge system failure. Battery recovers a bit, you can drive a short while again. At some point you cant start anymore so you would have noticed that :-) 6. coils fail getting hot. Unlikely they recover that fast if at all 7. weird electronic gremlins with connector loose or bare cable touching something. Solves itself because you brake and come to a standstill. Unlikely that would repeat itself exactly the same way. 8. Voodoo crap Best to look at the simple/likely issues first. Hope you dont get to 8.

-

check for kinked or ruptured fuel/vacuum/boost hoses. Sometimes hard to find. Or ruptured membrane in the malpassi. Could also be clogged fuel tank vent, that gives this symptoms too.

-

If its just a machine shop, they probably gonna recommend EDM/wirecut directly in hardened steel. Couple of problems with that: if it is trough hardened steel the gear is too brittle and EDM surface finish is not ideal either regarding wear and fatigue strength. You need hobbing, heat threatment and grinding. I'm by no means a gear expert, but enough to know that high performance gear manufacturing is a specialist job with zero chance of success if you dont know what you are doing. I dont think I need to paint a picture of a shattered gear set in your freshly build motor at 200+ mph..... I recommend to let a proper gear manufacturer do this, or not to do it at all.

-

I ordered at finjector.com

-

I have 17/40 too on a gsxr with hayabusa swingarm. A bit of a pig from standstill so taller 5th would be interesting for me too! Cant find it either. Regarding the maxspeeding rods, I'm about to install those too. Carillo's indeed crazy expensive. Big money to protect the engine, which is only expensive due to the .......rods. They used to have a cheaper version which were not H beam but seems they dont make those anymore. Dont really understand the rpm rating of the maxpeeding rods. A rating lower than oem makes no sense since everybody installing those rods will go to/over the limit....... Must be a mistake right. I put the rpm limit to 10K but that is more to protect the crank, and turbo engines dont benefit much from overrevving other than topspeed.

-

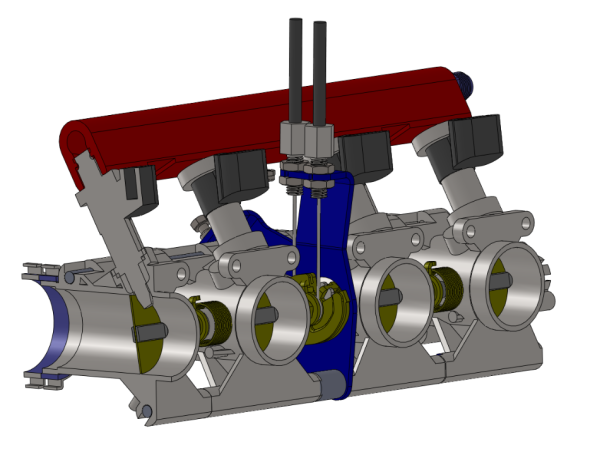

Yeah I measured them, put them in CAD and changed spacing and linkage to be in the center instead of at the outer end.

-

-

Imo it doesnt matter that much. Like batch injection: theoretically you will inject while inlet valves are closed which doesnt sound good. In reality it works fine. I can imagine if you are looking for that last bit of efficiency and emissions like automotive, this is important. For us, not so much.

-

Just used the numer I saw in his post: 45psi boost. Add 45psi base pressure, you are at 90 psi pump pressure. This results in around 225L/hr, which seems not enough to support the horsepower associated with 45psi boost.

-

Of course building stuff yourself will keep you busy with a nice project and you will learn a ton. Will you have the same result than even a budget unit like a microsquirt? Unlikely. One lean mishap and its very costly. My advice is to check the manuals of microsquirt: very detailed and useful, and valuable input even if you decide for another unit or the diy route. Manual for hardware, manual for software and manual for setting stuff up. I'm really happy with this stuff. https://www.msextra.com/manuals/ms2manuals/

-

probably because of the high presure. If you run the pump at 90psi it flows around 225L/Hr according to various people who bothered to do the test. https://www.google.com/search?sca_esv=04ccc06d6a14a3bd&rlz=1C1CHBD_nlNL1043NL1043&q=bosch+044+pressure+graph&udm=2&fbs=AEQNm0Aa4sjWe7Rqy32pFwRj0UkWd8nbOJfsBGGB5IQQO6L3J_TJ4YMS4eRay1mUcjRHkZxg8Vy0p2Xq9PcZNNq1Ew9zQooLZH5gQS3wVxeld5ohRXutwtU5CU2X36_uLH1pIUk5kgTFJ72LHrHs1dTrQZP2bShAIpXPbBXJuSHMpD67_7PI_IrPeKYP6OPe9Ff2p8rktfex&sa=X&ved=2ahUKEwim-rbVnLmJAxVygf0HHe-QCCcQtKgLegQIDhAB&biw=2560&bih=1319&dpr=1#vhid=SGOLBMIevLm8wM&vssid=mosaic So if you go north of 400hp I can imagine this will become an issue.

-

JE 79mm High Comp Pistons Machined For Turbo

peter1127 replied to ColinH's topic in Forced Induction

This is what I did: MTC 81mm 10:1 compression and milled them down to 9:1. See this thread somwhere on page 10. Of course this is for the GSXR1127 so you need to recalculate for the bandit https://oldskoolsuzuki.info/forums/topic/18853-turbo-gsxr1127-the-sequel/page/10/ -

Still better then 60pounds a piece on CMS......... But yeah everything is more expensive then diy

-

Detonation is the main engine killer on high performance forced induction engines. Following items will influence this: engine design Compression ratio. Stock is 10:1. You could use boost, but I think anything above 7psi is tricky and boost creep needs to be avoided at all cost. 8:1 is considered low and safe (if there is such a thing) so 15psi on 98 octane pump fuel should be fine. Low rpm performance and spoolup time suffers. Shape of the combustion chamber and stuff like sharp edges. Rounding those sharp edges in the head helps, also removing carbon deposit. Squish. Disadvantage of spacers and hayabusa pistons is that squish is too large to have the perfect mixing effect you are looking for. Then again, countless bikes exactly like this, so it seems more or less fine. Theoretically with a good squish band detonation is less likely How much mixture actually enters the engine: intake restrictions, valve size, cam shape & timing, exhaust backpressure Settings Boost level AFR: too lean at WOT burns pistons very quickly and promotes detonation. 12:1 is a good number to aim for, a bit richer on very high power Mixture temperature: the cooler the better. intercooler, chargecooler or water/methanol injection helps. A small turbo way outside its efficiency zone will heat up the air more then a large turbo which is nicely in the zone: same boost, different results. Assuming petrol: octane nr. ignition timing. not too advanced. I'm using 35 degrees at zero boost up to 30 degrees at 15psi Duration of runs = heat buildup. Dyno runs are more forgiving but when doing extended and repeated topend runs, that's a different story Since there are countless configurations, settings and situations possible, its difficult to give hard numbers especially if you want to know where the limit is. You will know when you go over it Best to look what others are doing and relate your plans to that. If you aim for 160-180rwph, you could use a fully stock unopened engine with something like 5-6psi. But what is the point If you are aiming for 200rwhp, that could be something like 10psi on a stock engine with 9:1 CR and 98 octane. Clutch might cope. Still hardly enough. (I have around 200RWHP on stock engine with spacerplate 8:1 CR and 10psi, and in process of upgrading the engine to allow for more power) 250rwhp: could be like 15-18 psi on an engine with 9:1CR and waterinjection/intercooler or 8:1 CR without. Stock pistons and rods might let go at some point, lockup needed. Imo a good number for the street. I'm aiming for this, or a tad more, with 9:1 1216 MTC, proper squish, maxpeed rods, ape studs, EFI, TD05-16G turbo, MTC lockup, stock head/cams, 98octane, possible waterinjection (still thinking intercooler somewhere) 300rwhp: could be something like 22-25 psi on 8:1 CR with waterinjection/intercooler and definitely proper pistons, rods, studs, lockup. Bit much for the road I think >350RWHP: dont know. Other people here have experience, even sombody here aiming for 1000hp......... Larger valves, flowed head and/or larger capacity will give a bit more power, or less boost for the same power. (just my 5 cents, results may vary)

-

APE valve guides are 260pound a set on suzukiperformancespares. Not cheap but not crazy.