gorbys

-

Posts

182 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Posts posted by gorbys

-

-

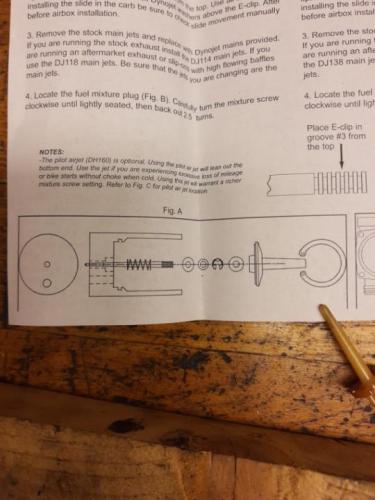

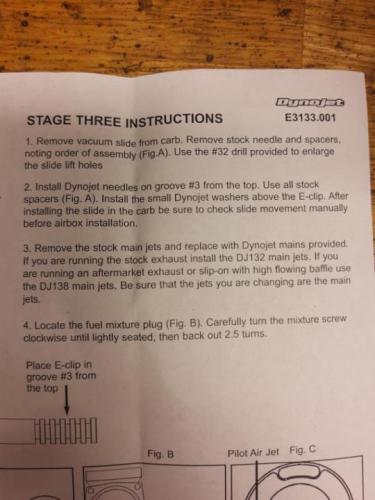

Okay so I got my dynojet kit for my gsx1100 and it doesn't mention any thing about the fat nylon washer.

It also says to install the dynojet washer on top of the e-clip but the drawing shows it underneath the clip.

So pictured is the stock way, how i assembled it and the dynojet instructions.

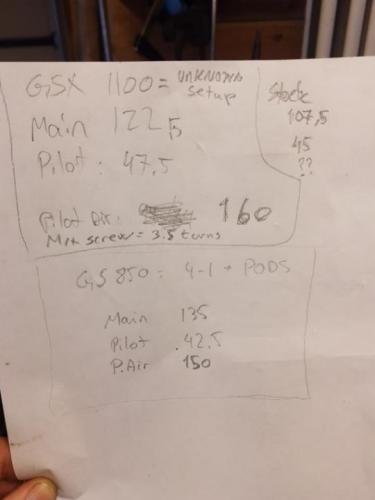

I checked the instructions for a gs850 out of curiosity(since I have a set of those) and it specifically mentions as well as shows the fat nylon washer in those. And the order there is washer, small dj washer, eclip and nylon washer. It also mentions air correctors. Is that what is screwed into the main jet air hole on my gs850 carbs? Last picture.

-

I put a gsx1100 engine in my 77 gs750. The rear lower fit. And I could bolt in the front one too but it made the engine tilt too far forward so the rocker cover touched the frame. So I made new brackets for the front and the rear upper

-

2

2

-

-

2 hours ago, Gixer1460 said:

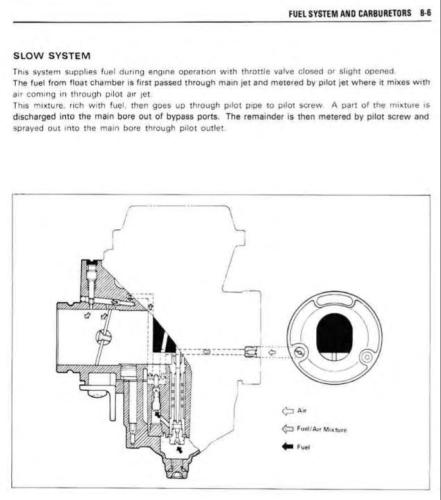

I may be old and stupid ( some say definitely) but looking at that picture - and assuming the circuit on the left is the pilot / low running circuit) how and where is that connected to / influenced by, the Main Jet apart from they share the same float bowl? You can remove or can block a MJ on most carbs and the engine will still idle - how, if interconnected?

It's either a simplified scheme or the Harley carb separates the two. But on the suzuki carbs the pilot jet is blocked by a rubber plug and gets its fuel via MJ.

-

On 9/20/2021 at 5:19 AM, TomP said:

Hi, can you post a picture of the screw you're adjusting? I always thought that the main jet doesn't enter the picture until wide open throttle. However I'm still learning.

The pilot jet gets its fuel supply via the main jet.

I can recommend this video for how a cv carb works.

The difference for us though is that the mixture screw is at the top and like I said, the pilot is supplied via the main jet.

-

5 hours ago, no class said:

3 3/4 turns is still waaay too much .

I know.

-

Just a little update to let you know that it responded nicely to bigger mains. I put the 135's in and mixture screws are now at 3 3/4 turns out and the throttle is definitely more snappy.

Still need to get jetkit as it's not enough but at least I can take a little testdrive up and down the street hopefully to see if everything else is OK with the bike

-

11 hours ago, Dezza said:

What carbs do you have? Different GSX1100s had variations on (mainly) BS34s with the last 'EFE' models having BS36s.

I don't know to be honest. It's an 82 engine as far as I know.

9 hours ago, Gixer1460 said:Its a GSX1100 so why not start with a richened up 1100 jetting to start - 4.5 out on mixture screw is waaay to far. ^^^ above doesn't sound a mile off?

No it doesn't, I think I'll start by just putting in the 135's to see if it betters. Untill I get a proper jet kit. I'll order one but I also need to order an upgrade kit for the clutch basket springs. I've noticed the little time it has run it's very noisy and today I took out the basket while changing the oil and 3 of the springs where loose. And the threads in the oil sump for the plug are probably gone as te bolt just goes round and round when you try to tighten it. So happy days

-

What size pilot jets are you running Dezza?

With that big main jet it's almost tempting to try the 135's i have just to see if it gets better.

I have been in touch with 6 sigma about a jet kit as I never expected it to run okay as it was.

Engine got a slight refresh before it was put in so its in good health, need to check the valves again as they where set cold

-

I just swapped in a gsx1100 engine in my 750gs(which ran 850 cylinders and top end, 4-1 race exhaust and podfilters).

I know nothing about this 1100 engine or its previous setup.

I have it running now with the pods and exhaust from the 850engine. It ran lean(as expected) so I tried to adjust the mixture but its still running lean at a full 4.5 turns out! So do I increase the pilot jet or the main jet as I understand these are sort of intertwined in their operation? I have checked bot the 850 carbs and 1100 carbs and the included jetting is attached in the picture. Seems the 1100 is jetted slightly higher than stock so might have ran an exhaust previously? Mix screws where 3.5turns out.

Have not road tested it yet, still on the bench as I'm working on brakes.

-

3 hours ago, Poldark said:

Just remember to match the appropriate ignition coils to the breaker points; 4 or 5 ohms. Electronic ignition systems are normally 2 or 3 ohm. Running points with the lower resistance coils will work fine for a short while, then break down and leave you stranded; been there.

Good point. Didn't think of that.

Lucky I'm still using the old coils then

-

Bolted straight in! Happy days!

Here's a video of it's first start up:

https://www.instagram.com/p/CTmwRfLlSQz/?utm_medium=copy_link

I am so happy now, this definately gave me som fresh motivation

-

2

2

-

-

Can I swap the points ignition from my gs750 over to my gsx1100 motor as a temporary solution untill I can get a hold of either the stock ignitor or a dyna s or something??

I'm at the point now where the only thing keeping me from starting my gsx1100 swapped gs750 is the ignitor I never thought about until I couldn't get spark today

-

1

1

-

-

So I stuck a 82 gsx1100 engine in my 77 gs750 frame and the Front and rear engine mounts are too short(the "triangles"). So I was just wondering if anyone has drawings of the correct mounts so I could send them to a machineshop and have them cut out so they're ready to go when I return from vacation.

Or is it as easy as getting the 1100 mounts from a breaker and the whole thing will magically bolt up?

-

-

I tested again today with good success but then idiot me managed to snap a piston ring when removing them so time to learn how to hone cylinders as well I guess and buy some new piston rings... And off course everything is closed now because some long haired hippie died two thousand years ago....

-

16 minutes ago, dago said:

I normally use petrol if it doesn't leak after about 30 seconds you're fine , water I'd probably leave for a few minutes

Oh, I fucked up a little bit then as I've left it for the last hour

There was some moisture in the exhaust ports. But yeah, it's sat for the last hour so. Probably not that bad

-

7 hours ago, dago said:

Yep springs, retainers and collets on and turn upside down

Cool. How long do I leave it sitting?

-

So for the water test the valves need to be assembled with springs and everything?

-

I was told to use windshield washer fluid by the guys who run the machine shop.

-

Yeah if you search YouTube for "how to lap valves" there's a ton of videos where people use drills to spin the valve while lapping. Also several people explaining why you shouldn't

As for the oil burning i definately can't rule out worn piston rings either, but I do feel that since each and every one of the valve stem seals shattered like glass upon removal that that's the main issue... I have yet to measure and inspect the pistons/rings and bore yet as I've been too occupied with other stuff these days. I'm crossing my fingers they're good but with the luck I'm having lately....

I also received a reply from the local engine shop and they said they could grind the valve seats. Replacing them would be really expensive though. They also said a little bit of pitting wouldn't necessarily be the end of the world as long as its not leaking. So like you said if I'm in a pinch...

-

I compared the L and the R yesterday and they both have the same curvature so I can't find any reason it wouldn't work. Yeah I noticed they're about 25€ each so not to happy about that but mine have started to crack on the ends. They're still pliable but yeah.

-

19 minutes ago, TonyGee said:

are you putting new rings in ?

Wasn't the plan no. I haven't checked their specs yet though.

-

1 minute ago, TonyGee said:

what you've done so far is gona be an improvement, a nice fresh cut seat would be nice but if the budget won't allow it then it'll have to do. how did the bike run before you pulled the head off ? ive seen worse exhaust seats before and the motor ran fine. i know what its like working too a tight budget

I have no idea, I bought the engine second hand from a motorcycle breaker. He said the engine needed new stem seals because it was using oil. So I thought easy peasy, until I took the head off and found the pistons, valves and chamber covered in thick carbon deposits. So it's obviously been burning oil for a long time.

-

I'm at 1.1 now and haven't got all of the pitting away. This is looking bleak...

If I have to drill the seats do I require new oversize valves? Or if the seats can be replaced do I reuse the valves I have or buy new ones? Mind you one valve is now at the upper tolerance limit.

Yeah I would love to do a porting and bigger valves and cams and all that but it's just not in the budget. A simple overhaul with fresh gaskets and seals was basically all I could afford at the time being

Confused about needle washer and clip order

in Air Cooled

Posted

I see. Thanks for the information!

Hmm, on the gs850 instructions it does say to drill out the hole in the slide with the included drillbit but the air corrector goes in the hole for the main air on the front.

Maybe there's different practises I don't know