Allspeeds

-

Posts

904 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Posts posted by Allspeeds

-

-

33 minutes ago, Gixer1460 said:

Be wary with a run in 5th ! All dynojet dyno's have a speed limit of 200mph wheel speed hence why most use 4th - don't know about others but a half ton roller @ 10k rpm would pretty much go through anything if it got loose LOL!

-

Yah I’ve found 2 little improvements and one possible cause to do tomorrow on the assembly so hopefully she sorted then

-

18 minutes ago, Gixer1460 said:

Is this occurring on the dyno? It's a fairly abnormal operating condition ie. high load (tall gear) applied at a low rpm. If the dyno run was done 'all gear' you'd probably find it doesn't occur or to a lesser degree as the wheel speed is higher at lower load (gear) so the lock up tend to engage and apply pressure - just a theory?

Yah I get ya mate we have considered doing next session in 5th and rolling on from a higher rpm for similar reasons you have just explained

-

The only other possibility is that because my turbo boosts hard from low revs the lock up isn’t getting Chance lock before the engine spools up hard ??

-

Replacing the B plate (thin one) and judder springs with a full plate (I know I should of done this when I built the motor) I’ve also got heavier diagram springs cuming but I’m gona change my steals for new also the frictions are all new Suzuki but the steels were visually ok and within service limit however service limit is for 98hp not 300 plus so il swap them out

-

This is helpful feed back thank you least I have more than once in example to go off

-

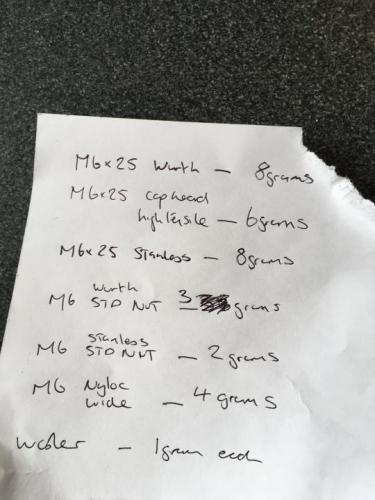

If you read my build thread you will see I’m having clutch issues so as a matter of interest I’ve weighed a few bolts and washers to understand more weight added to the lock up for further testing.

id be interested to hear what other people use or run weight wise

on there application weather it be turbo or high powered aspirated set ups just to give me more of a guide line to question further issues I may or may not have

on there application weather it be turbo or high powered aspirated set ups just to give me more of a guide line to question further issues I may or may not have

-

I would like to attend work depending

-

1

1

-

-

Yes I agree proper nice bikes from the best eras I didn’t manage to get the turbo done in time and I blew the bike I borrowed after 2 laps so lots of beers got drunk but nice to meet up with some faces from here a defo book again for next year great event

-

I’m there both days stopping the weekend

-

Nice little touch mate

-

1

1

-

-

Yah I’m booked on both days

-

Mite have a look up possibly going to enter the hill climb up there in October

-

9 minutes ago, Wee Man said:

Thanks @AllspeedsI wasn't sure if I'd like it will black wheels after the polished one. But it gives it a presence. Oh what a difference on the road, feels like a 600.

Yah I’m interested to see how much lighter the bike feels with the OZ wheels in compared to the heavy slingy wheels in

-

1

1

-

-

Looks really tasteful mate very nice wheels finished it off hope mine arrive this week

-

1

1

-

-

21 hours ago, Mark said:

I like the APE studs. Block was apart from the 1216 boring out, seems worth the spend for piece if mind to me.

I dont think you can honestly know if its money well spent, only way to find out is not spend it and have a problem. If they do there job you wont know.

I would want the piece of mind if you are covering miles on it personally.

Nicely put mate many an argument over ape studs

-

14 hours ago, vizman said:

The short pipes are not for looks.

This i am learning

-

Good food for thought this I love a turbo with an open pipe but sadly to use bikes in some places you have to put looks to one side.

-

Jaydee suggestion is a good way to get hem out without damage to calipers then replace pins but if you like to play in the garage a lot buying a set of exstractors is an easyer way and always handy to have I use mine weekly in the workshop triumph calipers pins are made of cheese!

-

-

36 minutes ago, Jaydee said:

Just make sure it's a 5.5 inch wheel that you are buying because if OZ are stating it's a 11K fitment then they might be offering a 4.5 wheel.

The advert does actually say 5.5 rear

-

-

Thanks for reply I’m happy now I know the disc fitment is all the same, oz wheels will come with there own sprocket carrier so if spindle sizes and spacers are the same but the only difference is rear wheel rim widths I’m good to go then

-

I’m interested in this question because I’d like mine to be track day friendly

Lock up clutch weights used

in Forced Induction

Posted · Edited by Allspeeds

Clutch all back together with new steels and heavier springs feels a lot better on the lever in terms of strength fingers crossed we’re sort now