-

Posts

1,172 -

Joined

-

Last visited

Reputation

784 ExcellentAbout Jaydee

- Birthday 06/14/1975

Personal Information

-

Location

Kildare, Ireland.

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

@Captain ChaosI had a set of 750J/K/L mirrors that I sold for €50 to a mate a good few years ago. And back then he though I was taking the piss with the price. They were identical to the 1100 K/L mirrors only the necks were (from memory) roughly 40mm shorter. Every other component was like for like.

-

I wonder what spacing powerscreen 1100 mirrors are. They are the nearest in style/position to the slingshot J/K/L mirrors that I've seen.

-

The item in the photo is 30mm spacing.

-

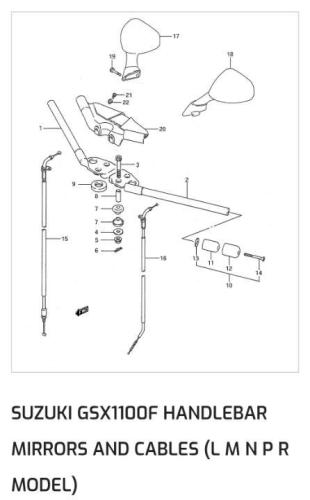

Wrong spacing for a J. 750 J/K/L and 1100 K/L have wider spaced mounting bolts. The ones in the link look similar to M/N style mirrors which have narrower mounting spacing.

-

As you have pod filters, it a quick job to pull out the carbs. Only way to properly check that the mixture screws are lightly seated all the way in, is to have carbs off and feel the mixture screw tip protuding from its hole in the carb throat. I suspect the o-rings in your mixture screws are hard/distorted and not letting the mixture screws seat fully. Either that or you have tight spots on your mixture screws. The mixture screws can't all be the way in and have a bike idling. The mixture screw tips completely block the slow circuit fuel supply on fully seated.

-

Is it not a reverse thread?

-

.thumb.gif.c71fd8dcce0a6f066ab2ce62a706b62a.gif)

k4 k5 fork yokes

Jaydee replied to Hacksawmad's topic in Water Cooled, V-Twins, Singles and 2-strokes

Have a k3/4 front end here. 207mm like said. -

Have a mk1 with a mk2 loom here. Something similar happened me. Bike died and had to wait for the battery to settle. Restart only to die 30 seconds later. Turned out it was the earth wire (single plug connector to side of) alternator had broken off. Battery wasn't charging. Once wire sorted, problem gone.

-

Never saw shrinkage on floats on any on the BST Mikuni range. I've worked on many, many sets. The float heights are 14.6mm. But there's a give or take 1mm is this measurement which would phase out influence of a slightly smaller (on a micro scale) float volume. With the floats being 30+ years old, the more common problem I see with the BST floats is warping. Where one side of the float is far higher than the other. This is more likely to cause inaccuracies in getting the right fuel level. Sometimes you can gently twist them back level. But some floats return back warped at rest which need replacing. I'm guessing your bike is an 11 M or N going by the 40's. I have ever only set up slingshot carbs by float height measurement. I find the method you are using is more for down draft carbs that actually have lines cast in to their bodies for a fuel level reference. No cast lines on BST's to go by so don't see the point.

-

Yeah, have 2 11L frames here with them on it. Only thing I can think of that Suzuki might have designed them for a future headlight subframe design mounts that they never went with. Either that or the raised bosses are some sort of reinforcement experiment seeing as it's only on some 1990 L frames and was never used in other years after.

-

Yes, 750 J, K and L are the same. The 1100 stuff is different.

-

Get on to Dynojet UK and Vicky will swap your used needles for new ones. Lifetime guarantee on DJ needles. Save the new kit or sell it on.

-

I'd bet my left bollock, he sent you more than a pic! When I enquired about the other EFE he had, he must have bombarded me with over 50 photos on WhatsApp. 90% of them were close ups of nothing worth a looking at. And I still didn't get the bike!

-

Same fella fucked me around a few years ago when selling another EFE (on Polish plates, but in Ireland this time. He was in Cork back then. He told me he worked weird shifts and I couldn't see him before 3pm to collect. I had a mate with van organised and had taken the day off work. I rang him at 12pm to say I was about to hit the road (3 hour journey) only to have him tell me it was sold and picked up that morning. That asshole was lying about his weird work shifts. It turned out he was lining me up as a back up plan in case his first sale fell through. This was at my expense seeing as I had to throw a few quid towards my my with van and lost a day's pay. As for him selling lots of bikes? Not happening. He was selling the EFE I was after for €4000. The one you were looking at was priced at €2650. Irish bikers aren't short of money and that bike should have sold 10 time over in Ireland. All his bikes are located in Poland or along the German border. He prices them low but never mentions anything about the fact they aren't in the country and need shipping which is a hidden extra on the price.

-

Is the guys name Richard who's based in Longford? He's had that bike for sale for over 2 years. Anyone enquring soon finds out its in Poland (not Ireland) waiting on a hefty deposit before the logistics are mentioned. Puts off people.