-

Posts

155 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Posts posted by TiZiK

-

-

8 hours ago, Jdeac1981 said:

Thanks for that. Is it the same measurement on both sides.?

Pretty sure the sprocket would sit further out so the chain could clear the tire

-

21 hours ago, Tombola said:

If it was me I’d Join the cam lines together, whatever happens you’re buying more fittings.

I think you're right mate. I had a look earlier and I think I have a line that'll work to join the cam Oilers. Just have to get a fitting for the turbo oil feed. (-3 to M12 x 1.5)

-

8 hours ago, Tombola said:

Nice job! Is that thin wall pipe going to the head?

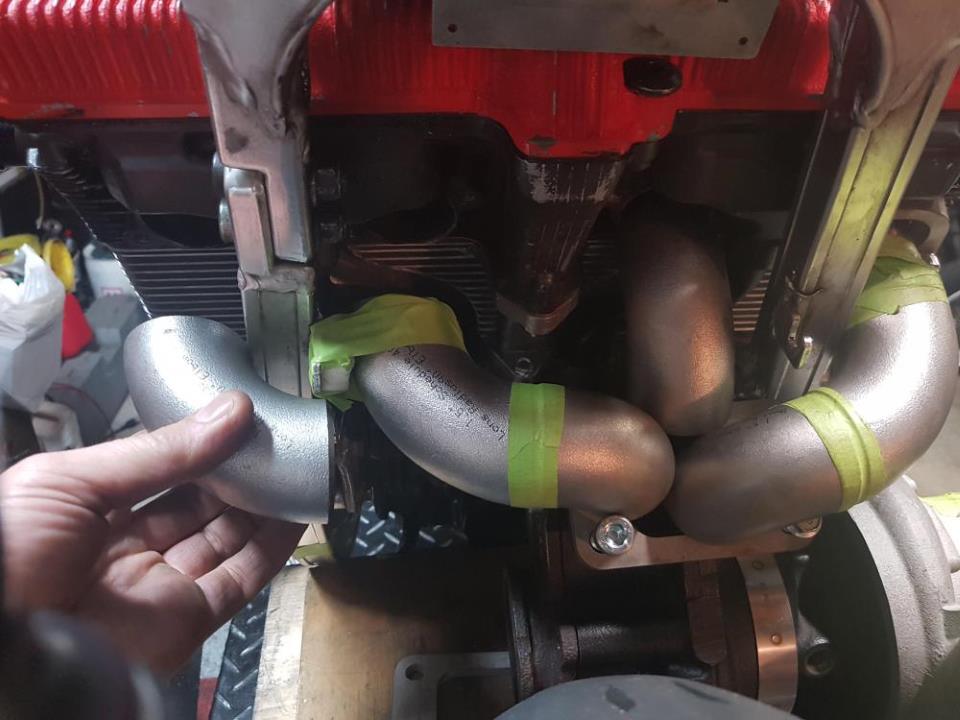

Thanks man. Was no easy task that's for sure. The pipes going to the head are 1¼ sch 10 and the rest is 1½ sch 40. The 1¼ sch 10 fits perfectly in the exhaust port area so that's why I used it there.

-

-

8 hours ago, clivegto said:

What about using a triple banjo bolt.

Is there such thing??? That'd actually be the quickest and easiest solution.

-

I was hoping there was another spot to draw from so I don't have to re-configure the lines I've already done

-

1 hour ago, no class said:

..... if you are using banjo type fitting at the oil feed..... simply use a double long banjo and seperate line to turbo .

Do you mean from the main gallery on the RHS below the ignition cover? if so, this is my conundrum. I am already using this with a double banjo for 2 separate lines to feed the cam oilers.

-

10 hours ago, Gixer1460 said:

Use one of the cam lines to feed turbot and split the other with a tee piece the two short lines to cams.

I think I might have too. I was hoping there was another access to the main gallery so I don't have to re-do the cam lines.

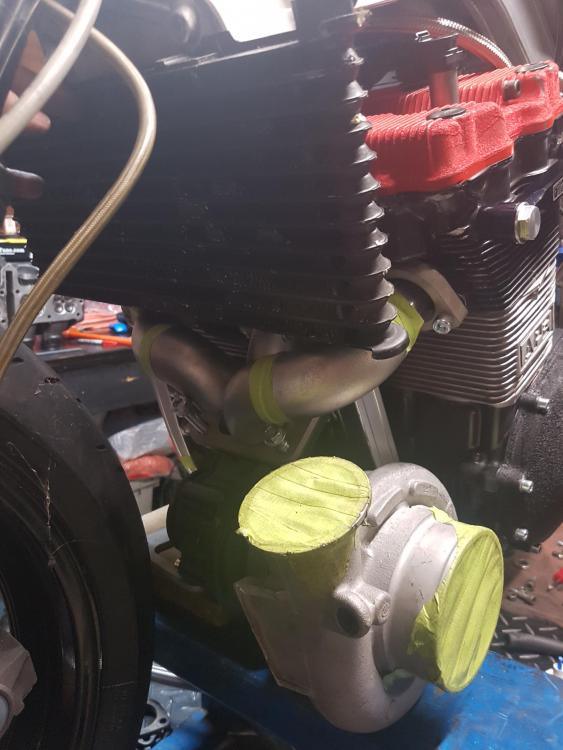

8 hours ago, Fugly said:How big is that snail????????????????

Hehe Holset HY35

-

1

1

-

-

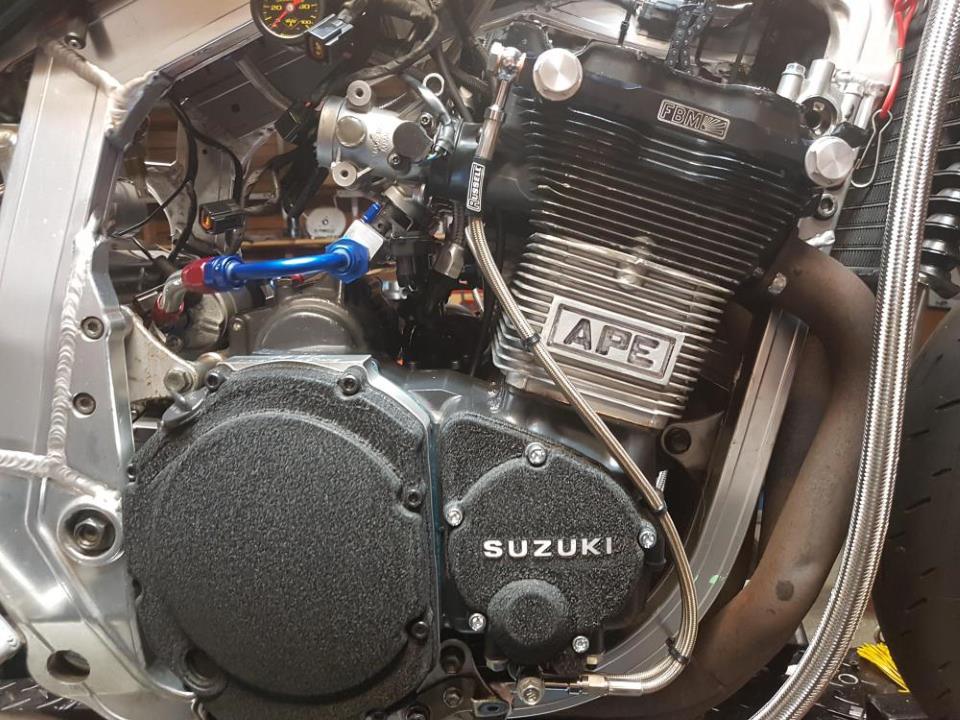

Hey guys.

Have a tad conundrum. I need an oil feed line for the turbo, BUT, I've already drilled and tapped the main plug on the RHS below the ignition cover and am already running a double banjo to feed the top end oiler kit.

Aside from reconfiguring those lines, is there another suggested spot to pull oil from?

TIA

Pic attached just because everyone loves pics.

-

1

1

-

-

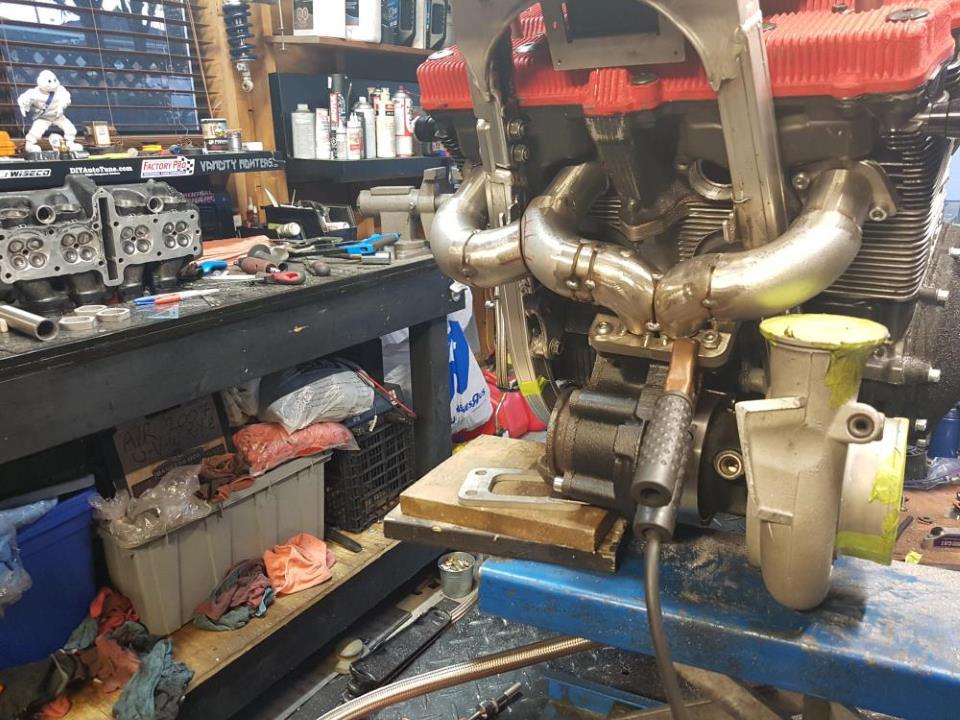

I hacked the frame brace off in the front. Lol

I entertained the thought of side mount. Didn't see it being any easier to fab up headers tho. Plus having to support the weight of the HX\HY.

The HY I'm using has the same compressor side as the HX but uses the 9cm single entry housing. Considerably smaller than the 12cm.

At one point I was looking at getting a lighter a\r .63 housing and having it machined to fit onto the HX. Turbo Lab America offers this but the cost was more than I wanted to spend

-

On 30/10/2017 at 8:28 AM, Arttu said:

Few comments:

-

Have you tried placing the turbo on other side of the bike? That could make things a bit easier. Or not.

- What size are the bends? Looks like they could be smaller which would make fitting easier pretty much everywhere but especially at collector.

- Forget about equal length. As far as I know it isn't very important with turbo headers.

Just for an example, here are few pics of header that I have on my current project. It isn't HY35 but similar sized HX35 based hybrid so fitment should be quite similar as well.

I did try placing the turbo on the other side. Just couldn't get it to sit nicely and have it high enough and enough clearance for the wheel. I am using a 2001 r6 front end (reworked to suit) so maybe the offset has my wheel sitting back a bit more that others? I don't know.

The bends are 1.5" in long radius 90* and short radius 90*. They're working out ok so far.

Have you modified that HX? I ask cause I have an HX as well but it's fucking massive! Mine has the 12cm twin scroll housing.

-

Have you tried placing the turbo on other side of the bike? That could make things a bit easier. Or not.

-

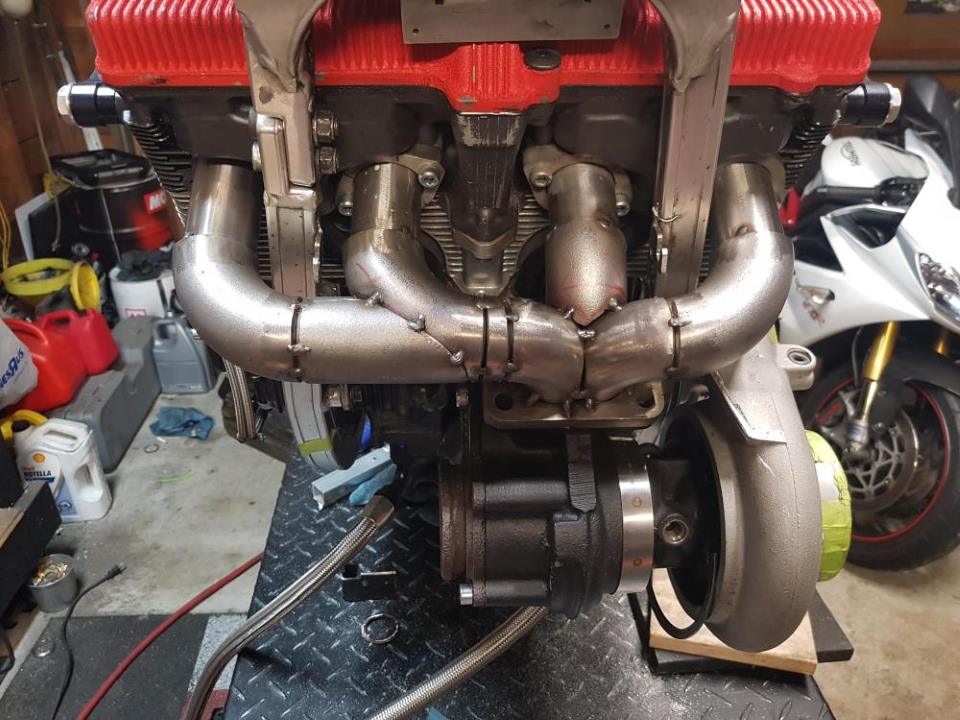

Now, I'm by no means making any claim that I'm some sort of fabricator. In fact, this is my first go at making a set of headers or anything of the sorts. I did, however, gave a damn good try this weekend and decided to go ahead and work with what I have. The process was fun and I learned a bit too.

Just one more runner to do and I'm going to change that small bend on the #4 runner to a straight piece so it comes into #3 at a straighter angle.

I'm pretty happy with it so far. If it's absolute shit in the end, I'll have gained some experience at least and will give it another go.

-

@no classForks were raised in triples to replicate full compression. Centerline of turbo is pretty much in line the the very top of the sight glass so I don't see any issues there. Also, this bike isn't gonna see much street riding. Going to the strip with it mostly so not too worried about left turns, wheelies etc. It also stretched at the rear.

I used sch. 40 cause my friend had these bends on hand already. I agree that it's heavier but it'll help retain heat for the turbine at least. I'm going to be adding a support bracket to help with the weight. Also, I had new exhaust flanges water jetted from 1\2" 304 SS. They sit flush against the mountings if the head and add some support.

-

Hey all!

Started on the next phase of my project. The boost phase. Went through a bunch of ups and downs regarding turbo placement and header design.

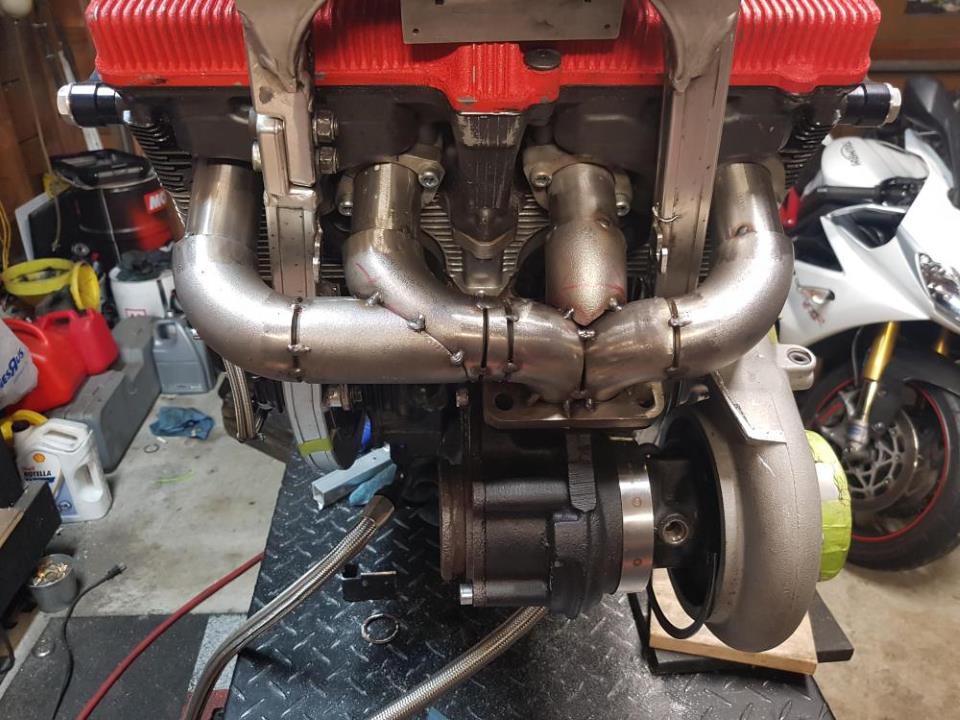

Turbo I'm using is a Holset HY35 with the 9cm turbine housing. Initially, I had an HX35 but that turbine housing is just fucking massive so settled on the HY as it flows close to the HX but in a slightly smaller package.

I cut the cross brace out that sits at the front just below the oil cooler. This allowed me to get the turbo high enough and back enough for oil drain and front wheel clearance.

I started laying out the piping for the headers. Knowing that ideally, you want like cylinders feeding each other and equal length etc, it's just not gonna happen. No space.

In the pics, you can see my current layout. Its the best I can see so that the turbo has a nice lil home and the pipes don't interfere with the oil cooler. I'm using sch.40 1.5" piping btw

Figured I'd throw it up here and see what some of your thoughts are. Maybe you guys see something I don't? Possibly a different solution?

T.I.A

-

Got her back together with new cams and rockers. Oil pressure is all good now.

Thanks is again for the help, can't say that enough. You've saved me thousands in $$$ and even more in tears.

Guess I should get around to getting an update on my build thread so you guys can see what I'm up to.

For now, she sleeps. Its beer time and Motogp!

-

4

4

-

-

Big thanks again for the help!

Ordered up 2 Russell lines from the local supplier. One was 36" the other 18". Both use a 10mm straight banjo on both ends.

I wanted to get in this straight away and didn't want to wait for a fitting for the main gallery, so I drilled and tapped the 8mm Allen original plug to accept a double length banjo bolt. I tightened it down by using a bolt with a nut threaded onto it so I could tighten the plug and hold the nut with a wrench to loosen the bolt. Worked a treat and looks pretty tidy!

Now to replace the cam and rockers and make sure the oil is getting up there.

-

7

7

-

-

11 hours ago, Gixer1460 said:

I've not known anyone go through the brass plug which is just a plug for the bored gallery behind - save the aggro and just double line from the RHS, job done.......... or single line from gallery to a tee piece to equal length hoses up to cam links...... if you are OCD!

I'm not THAT ocd, but do like things somewhat tidy.

New line in order. Hopefully get around to sorting this out tonight.

Cheers again guys! Appreciate the help.

-

Hahaha... that should have said "Cheers Suzook and gixer1460"

I have spare rockers, rocker shafts and a cam that I'll put in.

Picked up my oil lines on the way home, didn't realize there isn't a matching oil gallery on the left side.

Should both lines run off the gallery on the right?

Or are one of these in the pics suitable?

I realize that's a brass plug in the one under the starter clutch cover, just wondering if it's high pressure oil behind it?

TIA

-

Cheers Suzook and say what now!?!

Just ordered up some lines and will sort this out tonight when I get home.

-

4 minutes ago, no class said:

Probaby over-bored the cases....

Bingo!

-

1 minute ago, Gixer1460 said:

But real question is, why no oil up barrels............or did you block off the gallery at the base of the barrels?

That's correct Gixer1460. I'm using 85mm block and the gallery that feeds the top end was cut into when the cases were machined to accept the larger sleeves.

Thanks for the replies guys. I see where I went wrong now. Its kind of a blessing I guess. Even if it had just enough oil to not damage itself while running in the bench, with my next step being a dyno session, I'm sure it would have totally destroyed the head then. All the info I found previously about big blocks and top end Oilers had no mention of running a line from the main gallery. I guess it assumed the cases weren't dry blocked.

I need to order up some 16 x 1.5mm to an-4 fittings and some banjos to run a main line from the bottom main gallery to the top end oiler.

Along those lines, do I run 2 lines from the bottom main galleries? 1 line for each sides' top end oiler?

-

6 minutes ago, Gixer1460 said:

Just your description is wrong! 'Dry blocking' has no oil flowing through the block AT ALL - the galleries at the bottom are blocked off and an external oil line is used from the main gallery to the cams directly. You have an 'auxillary' feed from the low pressure / high flow cooling gallery. Does beg the question why you had no oil from the cases though.........if you don't have an external feed! And that connection on its own won't provide the oil pressure required!

That's right. No oil through the block at all.

So I was wrong in assuming that the connection currently on the top end oiler was sufficient enough. F#@k! At least the head is ok and I have spare cams and rockers.

Should I do away with the small line from the cam cover and run another line from the main gallery?

Possibly this one here in the pic?

-

Just pulled the intake cam. Got really lucky. No damage to head at all.

Did I make a mistake in assuming that with the top end oiler connected the way it is, that that'd be enough oil?

-

Yes. The oil gallery in the case was blocked. The top end oiler kit attaches to the cam cover to feed oil to cams... apparently.

Was I suppose to run a line from somewhere else?

I searched and searched on dry blocking and didn't come across any mention of having to run a line from elsewhere.

Luckily, the head is ok. Guess I had enough assembly lube to save it. Just the intake lobes got knackered.

Here's a pic showing the top end oiler kit.

Short Stoke Big Bore

in Oil Cooled

Posted

Not sure what's available but I do know that JE (and maybe other companies) will make you a piston in any configuration you want. A friend had a set made tomhis specs and they weren't much more than an off the shelf set. Might be worth emailing a couple companies to see what they'd charge.