-

Posts

155 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Posts posted by TiZiK

-

-

2 hours ago, MeanBean49 said:

I really dont understand what youve done here, that bit you have blanked off supplies the cooling oil for the cylinder head?

Why you are plumbing into the low pressure system doesnt make sense either.

Surely all you need to do is take an external feed from the crank plug and feed it into the cam plugs whic lh replicates how the system is designed to work.

That to me us a recipie for overheated head and cams, and a crank with too little supply pressure

Surely it'd be nice to get some recommendations for a solution when the question is first asked instead of the solution criticized after the fact.

Crank doesn't have a pressure issue. The cams did. The 2 ports I plugged in the valve cover were wide open causing a drop in oil pressure. Now that they are plugged, no more squeaky squeak. All the other ports and passages seem to have a restrictor in them to maintain pressure.

I'm no expert here. Another member with a similar setup as mine (big bore, dry block, turbo) had the same issue and this was the solution for him and his engine has been good since. Either way, something to be aware of. Take it or leave it.

-

-

Well, that's sorted. Thanks guys! Special shout out the Mikeyd for the detailed pm.

This is huge for me. Been plaguing me for almost 3 years. Had it stuck in a corner under a blanket. Now I can move on and finish the turbo system and tidy everything up before spring comes.

For anyone in the future venturing down this path, this is one of those lesser known, and at least lesser talked about, issues you may run into when you dry block.

-

Any company selling new chrome tubes?

Have a friend restoring a slabby and his chrome tubes are trashed.

Closer to Canada the better

TIA

-

On 11/21/2020 at 2:40 PM, Joseph said:

In 92 the 750 was a waterboiler too anyway, so it's not like you didn't get what you could expect to get with the info you were given

they're good machines, just use it as is

Ya, i was aware that the 92 was watercooled in some markets but I always thought it was 93 for the first year in Canada. Gonna get it running and see whats what. Pops the main fuse as soon as a battery is connected, so I'll sort that out and see how it is. Might be cheap fun at the strip next year. If it goes pop, Oh well, only cost me 300 maple bacons haha

-

3

3

-

-

14 hours ago, Swirl said:

Make the oil boiler fit

I thought of that but seems like a lot of work no?

From what I gather, mounts are different, frame interferes with exhaust, possible pet cock interference...

I'm open to it if it's not a huge undertaking. Don't want another "project" at this time.

Any links to browse and mull over would be appreciated

-

Hey gang. I work at a dealer and someone wanted to trade in a couple bikes. One of which was suppose to be a 92 Gsxr 750. Sweet I said! I'll take it sight unseen as I have a spare 1100 engine with 2mm overbore and high compression pistons along with a dot head to bolt on and swap in. Turns out it's a fecking 93.

It's partially set up for drag racing. Well, it has extensions and the the front has been lowered. So they attempted to set it up. LoL

I got it cheap. 300 Canadian beavers.

Might just keep it and beat it to death at the track.

What kind of ¼ mile times do these things run?

How much giggle gas will they take before they pop?

What would you guys do??

-

1

1

-

-

On 10/19/2020 at 2:55 AM, Gixer1460 said:

Wow! I didn't know anyone made 87mm pistons (assuming 1127 engine) or are they custom? I'd imagine liners would be thinner than recommended especially with a turbo?

85mm APE Gorillia block. Was a 1052 engine.

-

On 10/9/2020 at 4:04 PM, mikeyd said:

You definitely need to block the 2 holes in the underside of the valve cover otherwise you loose all pressure out those holes, ask me how I know. Street bike or race bike?

First thing I'll be checking. For now, it's a race bike. Maybe street it a few times here and there in the future but looking to make it a dedicated drag bike first.

I think with the larger CC engine and turbo, it'll be hard to manage the excess heat on the street. Be cool to take it to a few bike nights to show it off.

-

On 10/17/2020 at 9:35 AM, Fredrik_Steen said:

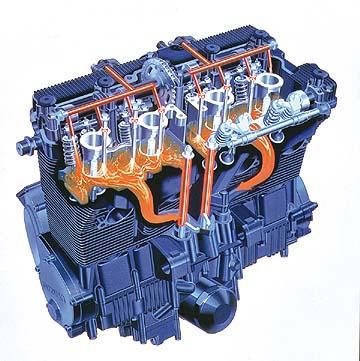

9mm overbore cylinder block so had to machine cases to fit the larger sleeves. This cut into the oil galleries that feed the head through the studs so I blocked and fed externally.

To clarify, I didn't block the lines off that feed to the valve cover for the cooling circuit.

I have a few things to finish off and then I'll get this thing back on the bench. I'll update where I'm at as it's been awhile since I last worked on it

-

The oil gallery that normally feeds the head is indeed blocked. I tapped it and blocked it with a 12mm length set screw with red loctite.

The valve springs are from APE so i agree that it shouldn't be a problem. Was just a thought that was passing through my mind.

When I initially installed the top end Oiler kit, I didn't use the valve cover ports. That was the first set of rockers cooked. I then connected them to see if that was the issue. Guess not.

@meanbean Do you mean the line i used from the main gallery to the top end Oiler kit? It's a -3 I believe.

I searched my previous posts and apparently I posted about this a while back as well. One chap mentioned that there are 2 holes in the valve cover circuit that can be blocked off which helps increase the oil pressure as well.

Any thoughts on that?

-

Hey folks. Been awhile since I've been here. Also been awhile since I worked on my project. I have a slabby that I've installed a APE gorilla block on. I had to dry block it. I installed a set of top end Oilers from Dave at Fast by Me.

I fed the top end Oilers from the main oil gallery and also the oil port in the valve cover. The turbo (Holset HY35) is also fed from the main gallery.

My issue is top end oiling. I think I squeaked another set of rockers and cams.

Had anyone else dry blocked an 1100 (1052) and added a turbo? How did you solve the oiling issues?

I also installed heavy duty valve springs which also has me thinking the spring rate may me too high.

I'm thinking myself in circles right now and need some outside chatter to make sense of it all.

TIA

-

1

1

-

-

5 minutes ago, Duckndive said:

They are only normally needed with very high lift cams and high valve spring pressures

Oil boilers have an abundance of oil in the top end

I have stiffer springs. Engine is also dry blocked and I'm running external lines. Also feeding a turbo which I think is robbing pressure\flow from the top end feed. Regardless, won't know until a couple months when I get access to the bike again. Gonna need a hard faced set sooner or later. Running out of good spares also. Haha

-

You guys have all the good gents over there. Youd think with a combined population of 400 million there'd be more options

Any idea what he charges?

-

1

1

-

-

After destroying one set of rockers and cams due to a top end oiling issue, I may have squeaked another set trying to sort out the oiling. Just moved across the country and won't be able to see what damage has been done from last time it was running as bike is in storage for a couple months. There was a small squeak coming from #1 cylinder cam area. Pretty sure at the minimum a rocker has been damaged. Sooner or later ill need a set of hard welded rockers.

I'm in Canada and the only place I know of is APE Racing in the States. They also charge $60 per rocker. With the exchange rate and shipping, I'm looking at appx $500 cad for a set.

Are there any other options besides APE?

-

I just found his listings again and he now has 2 different ones. 1 for the pan. 1 for the pump. Clearly they are different thread pitches. I sent him a message and asked him a couple questions to help clarify the differences and what pressures I should expect to see with just the one in the pan swapped out for one of his.

Out of curiosity, is your engine dry blocked?

-

@mikeydWould you know the increase in pressure by just swapping out the relief valve in the oil pan? And is 1 for the cooling circuit and 1 for the pressure circuit? if so, which is which? Hard to make out the oiling diagram in my manual

The second one thats threaded into the pump has a different thread size. On my engine, the 1052, the stock valve is 14mm x 1.25 but the modified valves I have are 16mm x 1.25. The 1 in my oil pan is 16mm tho

-

I tried to dis-assemble the stock one but stopped as I didn't see how I would put it back together without proper tooling\machines.

Haven't tried to dis-assemble the modified ones. Not sure myself why they cost so much either. Its just re-shimming the spring for a higher relief pressure and crimping it back together.

Maybe because they are the only ones selling them???

-

Being that it the cooling circuit, I'm gonna assume it's just to flood the head with oil to sweep away heat. Beyond that, I have no clue.

Either way, it's all good man. I got mine sorted for the time being as well and like you, I'm hoping to not have to remove that valve cover till much later this year as well.

Btw, are these the modified oil pressure relief valves you have? If so, with 2 installed, what kind of oil pressures are you seeing?

I have 2 as well but haven't checked pressures yet.

-

1

1

-

-

Would you have a pic of the weep holes you mentioned?

-

Thanks Mikey! Good to know. A bit late for now tho as I made up a set of new lines and pulled oil from the main gallery on the bottom right side.

May still visit this option down the road to tidy it all up. Engine is getting quite busy looking with braided lines every where from oil feeds and the efi. Lol

-

That's a smoking deal! Proboost usually uses a tdo4\5. Even if the turbo is damaged, a rebuild kit is like $100 and a new\used wheel can be had for cheap. I'm in the middle of making my own kit and if this was available at the beginning, I wouldn't have thought twice!

-

Ahoy and Happy New Year!

Making slow progress now that the cold has set in and the shop has more leaks and drafts than a screen door bottomed boat.

Managed to finish off the headers, get them and the snail mounted and got the oil feed line all sorted.

Getting around to the oil drain and have mixed info specifically pertaining to Holsets. Most info I read, including the Holset service manual, calls for a really large drain id. 16mm+. I plan on running -12an fittings and lines. This is just barely at the recommended id size. Some say it'll be fine but others say larger.

I know a few guys have fitted these HX\HY 35s to 1100s and am wondering what id drain was used?

Tia

-

I had a battery box made up and mounted it on the underside of the swingarm. I used a lithium battery to keep size down. Once mounted and painted to match the swingarm, it was barely noticeable. This wasn't on a gsxr but the idea might still be suitable.

-

1

1

-

Dry block big bore turbo oiling issue

in Forced Induction

Posted

Not trying to have a pissing match here bud. Read closer. You mis-understood from the get go.

Main gallery line to head has been removed as stated right above the pic.

There are 6 other ports supplying oil to the head which all have restrictor to maintain pressure. These 2 that I blocked have no restrictors and dump straight to atmosphere.

Also read the part where I said its a race bike, not a street bike.

Also read the part where another member with a similar set-up, who recommended this work around, has been running his like this for a couple years with no issues. Unless he went out of his way to fabricate a big lie which I highly doubt.

I'm just passing on the info for others in the future as none of this could be found online when I was initially searching before I even started to build the engine. I just hope it helps someone else out.