latheboy

Members-

Posts

71 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by latheboy

-

-

Not surprised you haven't seen it, not many people work on the little 750's haha

-

It's a 1990 750cc engine, "L" i think and the standard cable clutch on the RHS so it's a PULL set up. Sorry i just assumed that everyone knew what i was thinking Duckndive, is the shaft longer than the STD one? how much longer? I don't want to convert to Hydro, too much work for not enough gain. I have a full machine shop so making a new shaft is not an issue, It'd just be nice to use a off the shelf part if i can.

-

Hello. I have fitted an 1100 coil spring clutch to my 750 and it's a cable clutch. I use a MTC spacer and machined it down to the thickness i needed. I have fried the clutch ( which was second hand when fitted) so i'll be putting a new set of steels and fibres in but i want to fit a lock up because BOOOOOST. Has anyone fitted a lock up with a cable clutch? I'll have to get another MTC spacer or just make a complete new one (It needs to be 57.71mm) to give me the clearance but the cable pull shaft will be too short. I can make one, but if there is a longer on out of another model i'll just bang that in. Any ideas?

-

I have the answer for that question. It's twice as long as from 1 end to the centre!!!!

-

So, it's been a few days now.... does it rev yet

-

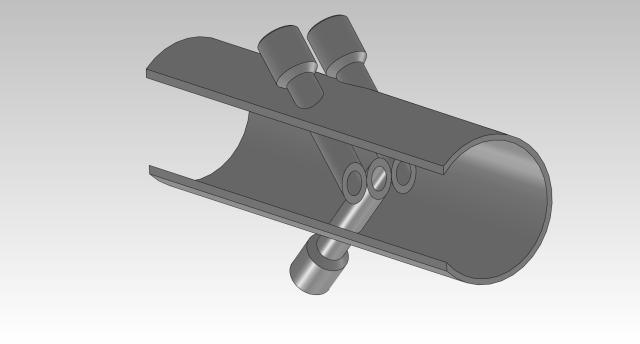

The welded pipe on the side is for the BOV, so its a dead end while running and boost but has a massive pressure drop for the pitots when the BOV opens

-

This was my first attempt at a pitot pipe. Like yours i had 1 that split to the 2 different fuel bowl circuits. DID NOT work and I feel like i had similar issues to you. I have drunk a lot since then sorry. Also i've a read through the thread and a couple of guys said to reference your Fuel reg of the petrol cock thingy thing so you get a vacuum, this is where you have yours now. Yes vacuum is great for the reg on shut throttle but i found it was pulsing and gave me the shits. I put the blow off valve right next to the Pitot pipes so the reg would see a pressure drop on closed throttle.

-

Ship it over here to Australia, they are pulling good money now days

-

Hmmm i must have read that bit wrong.... carry on

-

I think that is a bad idea, you are getting your boost reference from a place that sees a vacuum and reversion. It's too close to the valve. Hook up a fuel pressure gauge next to your boost gauge and while riding along trying to get on boost and watching the road for car/buses/animals/ other things that could jump out in front of you, hold your phone up and video what the gauges are doing... then on the way home watch the video while riding. No don't do that. I have 2.5PSI fuel pressure at idle

-

All i did to the carbs was follow the guide from the old site and i'm grateful for that information, thanks everyone. If this is all old news ... sorry it's just how i did it. Right then, i drilled a hole in each carb to get boost under the diaphragm. I did NOT modify the slides at all. This concerns me that you have. Boost referenced the fuel bowls (overflow) of each set (1/2 and 3/4) of carbys via its own pitot pipe Floats at Stock height Sealed the diaphragm breathers all together. Removed the fuel cock (hehe) and made new one that is free flowing out and a return that goes to the TOP of the tank. This is a must as the fuel return must be free of pressure. Trade off with the fuel cock (hehe) i made is i don't have a reserve now. STD one is a massive restriction. If its returning to the bottom of the tank you are fighting the petrol level pressure already in the tank. I sealed the petrol cock (hehe) feed pipe thingy on the carb rubber. I used ALL 4 ports in the carby tops to get vacuum for the blow off valve. I didn't cut the spring in the fuel Reg... bad idea in my opinion as it changes the spring rate to make it harder, i made a spacer for the reg that let me lower the std setting. Fuel Reg has it's own Pitot pipe. Wastegate controller has a reference off the plenum I machined the ignition plate so i could get up to 5 degrees retard When tuning, i had 1 AFR in the pipe and 4 EGT's, 1 in each exhaust port on the headers. I got the exhaust temps within 20 Degree C and the AFR happy each carb has different Main Jets and different needle heights Boost and Fuel Pressure hooked up too and made sure i had 2.5 to 3 PSI more fuel pressure at all times. There will be a test after you finish reading this

-

If it's inline with the air flow you shouldnt need to slash cut it. Don't know if the direction of the drilled holes would make a difference, it should see pressure even if facing backwards. I'm going to go look at it and see if i can think of anything else important i did.

-

It's been a long time since i've been on the dyno or any tuning. I think you should unblock the breather ports and link them between 1 and 2, 3 and 4 Yes they are the holes i drilled. Base fuel pressure on mine is 2.5psi and Is your pitot facing into the airflow? slash cut? I'll get back to with more.. i need to get shake my kids

-

The black rubber joiner at the top that is part of the breather system, if your carbs have this make sure it is sealed properly. I machined up some parts with o-rings so they sealed no matter what. Again, these are Ø38mm CV's so i don't know how they differ from yours.

-

Hi El Gringo, How many pitot pipes do you have? I have 3, 1 for the fuel reg and 1 each for 2 carbies into the overflow Ø46.8mm ID up pipe and the pitots are Ø6.00mm each. If you are getting ALL of your boost references from 1 pitot and spitting them over 3 places you might get problems. I didn't drill my slides when I set mine up, Ø38mm carbs, but I did drill a hole to under the diaphragm .. Ø3.0mm I think... it's been a while. To me It feels like the drilled slides are large part of the problem

-

Hey Slingy, how's it going? I've just rejoined, been a while. Didn't blow the motor, smashed the gearbox. Tom, the 750 Clutch is not up to the job for boost, retro fit an 1100 coil spring one onto your flywheel... fairly easy but I have a full machine shop to play with. T28 and 10 pounds all day everyday and 150HP at the wheel, yes lots of time on the DYNO but it's free. I have spun the clutch because I had "Help" one day put some new bits on and the wastegate controller was put on backwards. I saw 22PSI on the gauge when the clutch slipped but the motor lived. The 750 is well up to the task for boost, i'll fix the clutch and turn it up.....