Shill

Members-

Posts

67 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by Shill

-

Question on recommended clearance from the top of the valve cover to the bottom of the tank. On my B12 zuma, the gap is smaller than I'd like, <10mm. I'm imagining in some worst case scenario, say I forget about this and in a year sling a heavy tank bag on there, it could contact, and hot engine directly contacting a metal tank would be bad news. Is there a rule of thumb for this in terms of clearance? Plan is to space the front mount up with some rubber strips to gain an extra few mm - does anyone use any heat reflective / insulation material in applications like this? Am I worrying too much as long as there's some fresh air there?

-

Ah, I was figuring that the rough running was probably caused by the slide not moving enough, something to do with the reduced restriction effectively reducing the amount of vacuum it can pull on top of the diaphragm, so lifting the slides less. But I guess the pressure on the underside of the diaphragm is also downstream of the filter, so any change to that would affect them both, and the differential across the diaphragm is caused by the venturi, so is not significantly changed? I assumed the rough running was due to a loss in that pressure differential... but I suppose even if the diaphragm is moving the same amount, it's still fundamentally 'more air + same amount of fuel = not enough fuel'. Learning a lot on this project! And yeah, plan is to take it to the guy someone recommended at Meriden to get them set up properly. I've read the dynojet kits don't take so well to the mk2 carbs for some reason? Any knowledge on that? Hoping he can work some magic and either get a dynojet kit running sweet or do whatever else it needs, I ideally don't want to get into disassembling carbs myself (yet!). Really looking forward to getting the thing on the road! Edit: also ordered a breather filter - again a thing I totally didn't forsee going into this, lolz

-

Hey all, had the 1200 moving today, getting very close to roadworthiness! Clutch seems to working as it should. Not been out on the road yet, literally went in a circle in 1st gear. Wondering what’s the best thing to put on the end of the crankcase breather hose, a catch can or little filter? I’m not fussed about the look for now and really not keen on messing about with custom plumbing, is a filter on the end of the rubber hose generally enough? It’s smoking out of there a little which is a bit worrying, but again the thing hasn’t moved in a while so guessing it might reduce once it’s had a proper run and got up to temp. If it turns out it needs a rebuild I’m throwing in the towel and taking it to a pro Fuelling is obviously very unhappy with the pod filters, hoping it’ll be sufficiently rideable for MOT / getting to a dyno, seems to rev up to 4-5k but then die. Are there any temporary workarounds to improve running on pods before its set up? I’m wondering whether just masking half the surface with gaffa tape is going to help it pull enough vacuum to lift the needles? All feels a bit of a bodge at the mo.

-

Sounds like a trip to the Netherlands is on the cards!

-

Is there a ready source for cable sprocket cover lever return springs (you know what I mean!) Hoping it's a generic off the shelf part from somewhere. I broke my original one playing with the mechanism when I took it off Will stick with the hydraulic one for now since its on, but if it doesn't settle down I'll fit the old version.

-

Is the sprocket cover a straight swap? I didn't consider keeping the cable, what did you have to change to put the cable mechanism on the B12?

-

Ok cool, I got it filled and bled, but seems like the action is very low. With it in gear, if I pull the clutch in I *can* spin the wheel but there's a lot of resistance, very different to if it's in neutral. Will maybe bleed again next weekend, also that clutch hasn't been used in like 6 months so wonder if it might take a while to loosen up?

-

Hey gang. Slow progress on this, lots of life admin going on these last months. Anyway - B12 clutch basics question. I don't have experience with hydraulic clutch actuators so I dont have the feel for how it should be. Got a braided line on there and had the cover in place to fill and bleed it, then took it off to check the fit, and seem to need to compress the piston to get it back on. Is there anything I should watch out for here when fitting the cover? The movement on the piston seems to be very low - consider I'm used to the cable version with sone pretty visible in-out motion. Guess hydraulic is more similar to brakes, ie not a lot of motion but a lot of force? Also clearly there's no return action on the slave itself... So once it's in place is it a case of just pump the lever until the pushrod finds the point where it actuates the clutch, and then the clutch pushes back to 'return' the system to where it was when you release it? Pushrod seems in decent condition at the engine side, assuming it's supposed to just slot in (and have a bit of waggle to it). All just feels a little fragile and conscious of damaging it if there's anything I've missed. Sorry for super basic questions, just don't have the feel for what good looks like here, and obvs you can't inspect it when it's installed, so a bit of a black box. Current plan is open the bleed, force the piston back, close bleed, fit cover, pump handle a bit, then put it in gear and see if the clutch lets me spin the wheel, and if it stops when I let it out. If it works like a clutch should then I guess I'm ok. Cheers!

-

There's a guy on one of the fb groups selling some zuma forks, he's looking for €150 for them. Also he's in Italy. Bandit might be the easier option!

-

How's it running after a couple of weeks dude?

-

Nice one dude! Proper psyched to get mine finished, great to hear it's been a success

-

Looks good there Fred! When I move I need to set up somewhere proper to work in, this is the state of my workspace at the mo First stage every day is 'move all nonessential things out the front of the garage to make room to move around'

-

Nice one dude! Good to hear it went together ok,. Need to wait and see about coils on mine, that was definitely the clash point trying to get it in, didn't notice the contact once fitted. Mine's going together this sunday. Good luck tomorrow!

-

Apparently Fazer 600 fuel tap also fits and takes less space. Hope it goes well this weekend mate!

-

Think for the fuel line the other week I used the Bandit hose with the gsx clamp on it. Not as much ‘stretch’ in the hose over the tap outlet as you’d want, but the smaller clamp kept it tight. Would need to keep an eye on it.

-

Neutral switch was easy, timing pickup a little more fiddly. I'd say if you're happy doing the connector that's easier. Note the mk2 neutral switch has more wires than gsx (has a sensor to detect low gears as well as neutral?) so will need to find the right ones to join! On the 750 airbox, I'm not sure tbh, what carbs? That might be awkward, the 1200 is tight in the zuma frame, it's slightly taller, if you're using 1200 carbs they're bigger but not sure sure how much by in terms of length, I imagine it might clash. Haven't tried it though! I also found because of the extra height, my 750 headers hit the sump on the B12.

-

Using the B12 mk2 carbs, with K&n dual ovals, will need setting up.

-

It was idling a bit lumpy to be fair, could be any number of things but I'll try swapping it once it's back together.

-

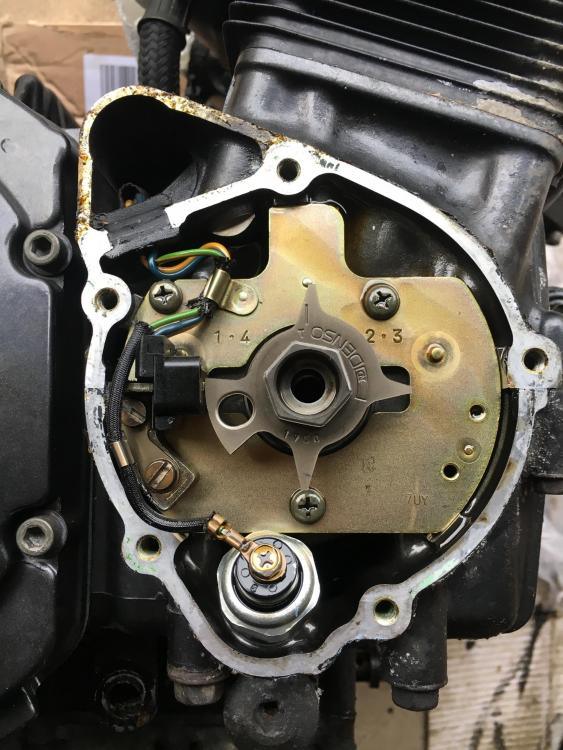

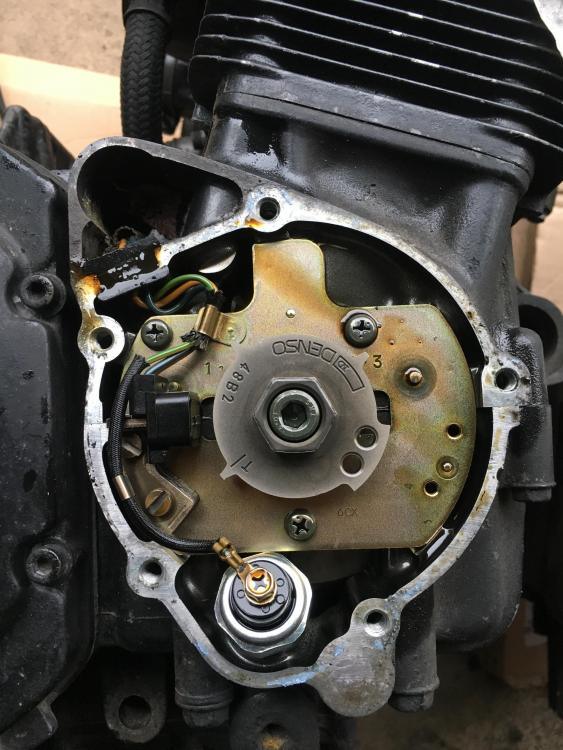

Maybe another mk1 vs mk2 thing but these were different, 750 is the skinny one, mk2 B1200 is the fat one. I assumed any difference meant I should leave the B12 on the B12, I have no idea how sensitive these things are - for instance the T mark is in line with the trailing edge of the 'leg' on the 750, vs the leading edge of the 'leg' on the B12. I took this to mean a slight difference in timing between the two (?) so left the original on there. Guess the other opposite argument is the 750 CDI works in sync with its normal rotor. Is it likely to make a noticeable difference?

-

Hey cheese, I am halfway through doing exactly this, think my thread is on page 2 or page 3. Also putting a Mk2 B12 into a GSX 750. I swapped the pulse gen and the neutral switch from the 750 to the 1200 so they will plug into the existing loom. General consensus seems to be that it will work fine on the 750 CDI, or the mk1 1200 CDI should plug in as a safe option. I have not changed the timing rotor itself, only the pickup. So far I've had it running and idling, but not on the road (now the engine is out again to drill the lower engine mount to the 12mm), so remains to be seen if that's an issue. Would people recommend changing the rotor as well? Have left the throttle position sensor disconnected for now as I was advised it "does fuck all"

-

Also cheers Cpt Chaos for the advice on the TPS - have left it disconnected for now, if i want to connect it it would mean some splicing (and I guess some multimeter fun to check it's the same output?) Any noob errors I should watch out for doing my first engine swap? I'm getting new washers for the cooler hose banjos, old exhaust seems to fit the new collector box OK with a new mesh gasket, new header gaskets, oil and filter, plugs... missing anything?

-

Hi gurus, Got the B12 in and running, brilliant to hear it fire up the first time! All I changed was the neutral switch and pulse gen to plug into the old 750 loom, the alternator connectors were the same so kept the one on the engine. It starts, it idles, everything seems to be working ok. This weekend it's coming back out to drill out the rear engine mounts to take the B12 mounting bolts (10mm -> 12mm as per a B6 ->B12 transplant?), then going together properly with new mounting bolts etc. Query on exhaust headers - I've seen a thread somewhere about 'half moon' spacers on the B12 that sit between the exhaust flange and the port on 2 of the headers. Is this something I need to lay my hands on? When I fired it up everything was put together a little loosely with old gaskets etc, when it goes back in for good I want to make sure I'm not missing anything. While I'm at it, oil coolers - I'm guessing the B12 has a bigger oil cooler than the little zuma - is this gonna be a problem? The fit into the frame is pretty tight with the extra height and new carbs, haven't thought carefully about permanently mounting the tank yet. The internet seems to say a Pingel tap will give enough clearance to keep the existing mounts, or the alternative is spacing up the back of the tank by some amount. Also getting these engines back in the frame is a bit of a bugger eh?

-

Thanks for the welcome guys, brilliant how much info is on here Will try with the inazuma loom first off. So what’s the rough price I can expect for a dyno setup? Got no experience of it, wondering how much to plan for. K&Ns arrived today I’m away this weekend so will put the 1200 in at start of Feb all being well. Edit: I do have the mk2 loom and CDI from Paul if needs be. Ideally want to keep the clocks and switchgear as standard for now though, think if I change the loom there’s other bits and bobs that’ll have to change to match. Thought if it’ll go with the existing wiring it’ll save a job for now.

-

First person to say it to me anyway

-

Thanks for the input guys. How much should I expect to pay for a dyno setup, is there anyone recommended? Shout outs to PaulM for the 1200 parts and to UKLee several years ago who was the first person to say "gsx750? You can put a 1200 in that!"