Shill

Members-

Posts

67 -

Joined

-

Last visited

Reputation

33 ExcellentPersonal Information

-

Location

London

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Is it a typical thing for breathers to smoke a lot more with fresh oil btw? Mine smokes quite a bit (and smells fkin horrible) after an oil change but seems to settle down after a while, I assume it's the more volatile compounds burning off... I hope it's not a case of the oil is spent by the time they've gone! Edit: Currently venting to atmosphere, obvs. Might have a play with feeding it back into the intake if I can find some 2nd hand dual pods to avoid butchering mine.

-

Awesome, thanks CC will bear that in mind. Trip went without a hitch, got back to the midlands yesterday, probably closer to 2000 miles all in. Bike pulled well all the way, used a bit of oil but no problems. We were really lucky with weather and the roads up in the North West are as good as they said they are

-

Cheers all for the input! I took out the old tensioner and it still had a few notches on it, so replaced it with the manual but happy with it for now. Good thing for my learning was putting the manual in there and being able to back it off a bit, hear the chain rattle come in and then tighten it back up. Upshot is the thing I was hearing seems to be something else around the front end just resonating at around 2k, I've checked everything it could reasonably be mechanically, rechecked the valve clearances, and suspect it's just something around the instrument cluster, mudguard or something. Got new exhaust gaskets and sealed up the connector box joint with liberal amounts of exhaust sealant. Hard to find the sound when it's not moving. I did about 150 miles up to Yorkshire yesterday, everything seems good, and setting off tomorrow on a trip up to Skye, across to the Cairngorms, then back down over the course of a week, should be about 1500 miles all in. Going with a mate on a 675 Street Triple, I'm glad to have the B12 lump for the motorways Think I'm just paranoid about noises. I think the engine is about 55-60k, but history is a bit of an unknown. When I did the top end last year, one cylinder was at the wide end of the tolerance on front-back direction, but not outside of it. I think mechanically it's sounding fine. Just smokes a bit out the breather when it's hot, which I guess is related to that cylinder. Will re-check things at the end of the year and maybe do camchain then. If it ever needs a rebore I guess that's a chance to big! Is there much of a downside to using a replacement with a rivet link vs doing a full stripdown with an endless chain? I've riveted a drive chain before, I guess cam chain is essentially the same process just smaller and more fiddly? Pic because everyone likes pics. Warning, contains one non-Suzuki.

-

That's good to know - I should get myself to an event see what the others oil boilers sound like. When I had the top end apart last year everything looked pretty much fine and within tolerance. I'll fit the manual tensioner and keep an eye on it, maybe save my effort for when something actually needs fixing!

-

Hi all, General question on top end noise. I'm getting quite a rattle on my mk2 1200, mainly noticeable if you give it a small amount of revs in neutral. It's not a harsh knock, just a general rushing chatter that sounds to my ear like camchain, and a same kind of whirring when you're on the move. Also getting quite an angry rattle from somewhere at about 2k revs, but this passes as you rev past it, I reckon might be just something loose resonating at that speed so might be a red herring. Annoying around town though. Anyway, the stock tensioner is pretty much fully extended, I think it had like 2 notches left when I refitted it a month or so ago, and gave it a gentle poke when I put it back in to help the spring. Definitely quieter now but still noisier than I'm happy with (my only reference for 'normal' is the original 750 engine I took out of it about 3 years ago, so memory is hazy and that had less miles on). I've already picked up a manual CCT off eblag which I think has more travel on it... but question is am I daft to ignore it and just try to take up the slack? I really don't want to do a chain replacement right now if I can avoid it. Going to re-check valve clearances too - I'm off on a Scotland trip next week so keen to have peace of mind for that. Thing is when it's moving it's hardly noticeable, performance is great, so I dunno if I'm just overreacting. I guess a 20 year old engine isn't going to sound like new. Maybe I just need to ride it for 2000 miles and chill out Edit: Reading that back I'm thinking 'yeah... that's what engines sound like'. But the tensioner question is legit!

-

I'd guess if you're not wringing its neck constantly it's probably exactly what the motors were made to do! Worthwhile cheap-ish investment might be an oil temp sensor in the sump plug or oil gallery so you can keep an eye on it and be on the safe side, but I reckon you'll still have headroom cooling-wise.

-

Yeah my understanding is it's partly the specific non-standard taper on the needles? If you only swap jets that assumes the rest of the setup is in some way still sensible/appropriate in a given running condition... if you've made a more radical change like ditching the airbox as mentioned above, you can't rejet your way out of the really significant change you've made to the airflow and fuel metering requirements through the rev range by just changing one part (considering that on CV carbs the needle movement is a function of specific pressure differences that are probably affected by removing the airbox). So basically, what they said above I have a kit on my B12 and it works great - it has a *slight* stumble sometimes moving away from standing at low revs+throttle, but not enough to inspire me to try and fix after 2 years so can't really complain.

-

Mine gave 76.9 lb-ft on the dyno at about 6.5k, stock mk2 engine with mk2 carbs with dynojetkit, K&N ovals, random aftermarket end can and PAIRS removed. Not sure on the exact year.

-

Bear in mind you'll want to do something to the jetting if you replace the airbox - there might be a 'stage 3' jet kit for the 600 but you're flowing more air in the 1200 so guess that won't be the answer... if you can, maybe Bandit 1200 carbs and jets might be the closest to a known good condition.

-

B12 top end rebuild @ 55k - Replace rings? To hone or not to hone?

Shill replied to Shill's topic in Oil Cooled

Yeah I was surprised at the condition of the bores - smooth to the touch but can still see the hone. Not sure on the history really, so a bit of a voyage of discovery! -

B12 top end rebuild @ 55k - Replace rings? To hone or not to hone?

Shill replied to Shill's topic in Oil Cooled

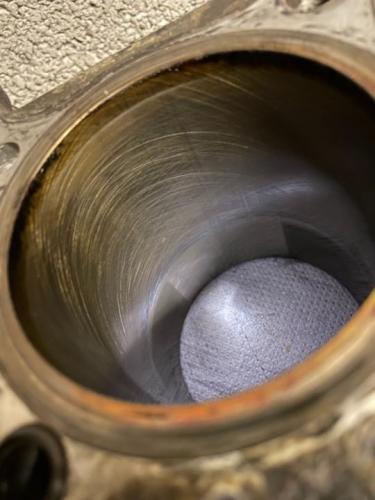

Cheers wraith, that makes sense. I should clarify, the smoking wasn’t from the exhaust but from the breather hose from the top of the valve cover, I’m running pods so just have the breather open with a generic filter on it. It smoked more once up to temp I’d say, I’d notice it when stopped after a long run. Is some smoke normal if you’re just venting to atmosphere? On piston and head carbon build up, couple of pics below. I didn’t expect it spotless, and kind of feel this isn’t too out of the ordinary? More experienced opinions very welcome though! The other side is cleaner, the inner pot on this side is the most carboniferous, and closest to the external leak on the front. Will find out more when I get measuring, guess that’s the real answer eh. Cheers for the input, I know this is more standard service knowledge than OSS madness, it’s in my zuma 7/12 at least! -

Hi all - sorry if this is an age old question, but I figure the collective experience on here is more than mine (basically zero). So, for reasons, I've got the top end of my B12 mk2 apart. Reasons are several: I bought the engine used (now has about 50-55k on it), and it's always had an mild oil leak somewhere on the front, so wanted to do the valve cover and oil tube seals anyway. Probably gonna paint it at the same time, and worth doing a general inspection. When I bought it I was just enthusiastic to get the thing in and running! There's always been a bit of smoke out the breather filter once it's warm. The dyno guy said 'its just breathing a bit heavy', which was kind of ambiguous (like "it's not ideal but it's ok") so it's always been at the back of my mind that it smokes more than it should. I realise at this point a compression check would have put those doubts to bed... which I didn't do. Main thing: Last week it was only running on 3 cyls (suspect caused by a blocked jet, I ran it down to reserve for the first time in ages recently). This has happened before and has cleared itself up by the end of my road. Not this time - it stayed running lumpy, and then at some lights there was a loud pop, and when I got home there was a good amount of oil in my breather hose and filter, and on the front of the engine. So something has pressurised the crankcase? Total noob hypothesis - I suspect this is maybe just unburned blowby from the weak cylinder getting ignited (does compression alone cause blowby if it's not firing?), but I saw this and thought f*ck, something's let go. Combined with my nagging doubt about the rings anyway, and the leak path on the front, I suspected gaskets, some disaster induced by lean running on 1 cyl, all manner of horrors. So here we are, head off, barrels off, looking for anything catastrophic, and turns out it's basically fine to my untrained eye. Bores very smooth with no scoring, pistons look fine, bit of carbon buildup on the head to clean off (suspect stem seals on 2 of the 4), oil line top orings look to be nicked so probably the source of the leak. Going to do valve stem seals and a general tidy up. Very much wishing I'd done a compression test before all this started just to have more data, but I do tend to go at these things 'like a pig at a tater' as my mate points out. Question is, at what point would you experienced OSS dudes be expecting piston rings to need replacing? On an engine of this age, would you re-do anyway while it's apart to be safe in the knowledge of a proper rebuild, or best left alone if there are no serious symptoms? I'll be doing measurements tonight but wondering what's 'typical' at 50k. Supplementary question - there's a load of conflicting internet views about cylinder de-glazing/honing and whether it's necessary or beneficial. I'm leaning towards new rings just to be thorough, and a light de-glaze because that's the standard recommendation, but any other views? Also, 20% off at Robinsons Foundry this Friday-Monday for Black Friday apparently.

-

Wemoto do a full gasket set made by Athena (looks like not just a top end set though for the 1100f?) , I've just ordered some for my B12 after having a read online and there seem to be pretty good reports. Guess a set is the best value - I tried to optimise it by buying odds and sods from different sellers (found an Athena base and head gasket together for £60 off eblag), but probably would've been best off just buying the set tbh

-

Yep, according to the SSC facebook page! I think the article on the Suzuki page was just published on the 9th

-

This is happening tomorrow, I'll probably head over for a gawp in the morning. https://www.suzukipress.co.uk/release/classic-suzuki-sunday-finally-returns-to-the-super-sausage-cafe/?fbclid=IwAR02HX9RTgZ_80_GusoSk6d4raEH_IWDSOu5r5RVqIdNaj-9ALNjXJWVJxY