luke2152

Members-

Posts

117 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by luke2152

-

I used your table exactly as shown for nearly two years and its been working fine. Today I had bike on dyno at SPR racing and Sam the owner (Sam is two stroke guru doesn't know too much of turbos) called his friend who does a lot of work on turbo bikes, who insisted I shouldn't use more than 24 degrees advance at full boost. Needless to say I was pretty happy with the timing I got from Arttu but I tried taking 10 degrees out of the table above 100kpa and smoothing just out of curiosity. The results? Pretty much made no difference which has completely boggled my brain as how can such that is a huge change to the timing have no obvious effect on the torque and power curve. Perhaps my ideal number is in the middle at around 29. Bike was a bit hot for any further dyno play at that point so didn't get to experiment.

-

Sorry for late reply mate. Yeah went well. Just went over the cracks and got a friend to do some of the hard to get at bits. Warped the header a bit and was hard to get back on but I suspect now its had a few heat cycles it will have shaped itself back to the way it was.

-

An unusual thought I had on venting the crank case. Could i vent the hoses straight to the exhaust about midway (I have a full exhaust). The idea being that the exhaust would work as a venturi to keep a negative pressure in the crankcase. But also that any sludge would get boiled off or burned up. Not sure how it would work in practice - whether it would be hot enough and whether it would smoke like a bastard.

-

I seem to remember someone telling me you could assemble bandit clutch with 2 stock diaphragm springs? Is it true. I think I have a spare one somewhere. And I'll put a bit more on the lock up arms. Seems strange that I did 1500mile on synth with no slip and within 100mile of putting mineral in it started slipping. Would expect the opposite.

-

I realise this is similar topic to another current thread. Bandit 12 with TD04@1 bar as per my build thread. FBM lockup. When I'm giving it some and the revs are up the lockup does its thing and no clutch slip. When I'm being lazy and just roll the throttle open in top gear, as I hit full boost before the revs are up it slips. It didn't do it before and strangely enough it started when I switched from full synthetic to mineral (must be coincidence?). So to that end (other than putting new fibres in) should I put heavier bolts in the flyout arms to make it engage sooner or heavier spring to clamp it better before the lockout does its thing. Or just stop being lazy.

-

Whistling at idle. Further inspection shows 3 major cracks in the headers. My god the engine is rock solid but everything else cracks on this bike. Admittedly the little waategate pipe brace was shoddy but the other cracks surprised me. What is best stratagy to fix them so they don't come back. fusion weld them and then make a plate/patch to cover them? I'm wary of making a big brace over the area as if it cracks again it could hide the crack or make it hard to access it.

-

Not been on a while so a quick update. Solved most issues. Have stuck with current pump walbro gsl392 mounted externally again. Using a new bandit 6 tank I picked up for peanuts on Eblag, used a td04 turbo drain where the petcock goes and added a return to the tank. Pump itself mounted low to give it a bit of pressure on the suction side and seems to be running great. Have made a 4th version of the turbo sump. this one is attached by oil hose only which gives it a little bit of movement to vibrate without cracking anything. The new tank looked so good I painted the half fairings to match (spray can job mind). Had it out at Rockingham last weekend and while I may have been lacking in talent the bike sure wasn't lacking in performace. Oil temperature still gets bloody high in traffic (the big oil cooler located near the headers exchanges heat the opposite direction at slow speeds) 135 degrees measured at the sump. I think that falls just inside the ok range for a good fully synthetic but I'm going to try and get a fan onto the oil cooler as well.

-

I'm using a TD04 - the saab one which is slightly bigger than the subaru and mitsubishi evo one. It spools up very quickly and I reckon its perfect for a road bike. Would use bigger if I wanted a dedicated top speed machine.

-

Good point but that's only a mapping issue if the injectors can keep up

-

What about putting this on a standard tank: https://www.Eblag.co.uk/itm/Suzuki-GSXR-600-750-K4-K5-Fuel-Pump-2004-2005-Petrol/112760737610?hash=item1a41104f4a:g:BsUAAOSwKXdaX4T- And then replacing the pump with this: https://www.highflowfuel.com/i-23908176-quantum-255lph-performance-fuel-pump-for-suzuki-gsx-r600-2004-2007-replaces-suzuki-15100-01h00-15100-01h00-e00.html?ref=category:335669 In tank regulator eliminates return line.

-

good idea but the hole is too small. Also not the lowest bit of the tank

-

Im at 225bhp and pretty happy with that with a little headroom for say 250. Maybe its not such an idea....would be such a nice packaged solution too

-

Right I've been lazy over the winter trying to save a bit of £ and there's far too much salt on the roads to make me want to ride anyway. I'm thoroughly annoyed with my multiple attempts to get the fuel system right and thinking of hitting the restart button (and make fuel system OEM as I can). I was thinking of fitting a bandit 1250 tank and pump. I'm not sure it will fit but looks like it would need minimum modification to do so. Then decap my injectors to bring flow rate in around 800cc/min. Bandit 1250 pump has one outlet and no return so I presume it has internal FPR @ 3 bar or so. Obviously will need to redo my mapping etc. Will a stock bandit pump actually move enough fuel for turbo application. The injectors will deliver loads of fuel but the pump needs to get it there. That said I suspect most pumps will deliver higher than intended flow rate much easier than higher than intended pressure.

-

Anyone per chance test fitted a fuel injected bandit 1250 tank onto a b12 frame? Been looking at pictures and they look pretty similar. I would expect to have to make a new back bracket but it would be nice easy step to fuel injection if the front end just slotted in ok. (I want to completely redo the fuel system on my turbo bandit using as many oem bits as possible).

-

I'm wondering if the fuel return right next to the filter sock in the tank is a bad idea. Thinking the fuel might be aerated when it returns and doing no good releasing it next to the pump inlet. Regardless I think the pump is completely toast now. Took it out for a go today and it ran lean a couple of times so I stayed off boost completely and it would periodically just go super lean (18:1 AFR) and I'd have to stop for a few minutes, then restart and it would be ok for a few more minutes. Barely made it home. New pump time and I think I'll run a hose for the return inside the tank to keep it well away from the filter sock. Bike is being such a bloody tease when its so close to being awesome!

-

Well its not debris ingestion because its always been filtered but may well have damaged itself when starved before - or it could just be bad luck.

-

And after all that the fuel pump is still screaming. Maybe its buggered. It does it about 80% of the time and then sometimes shuts up for no obvious reason. And it really is loud. Louder than the bike at idle. Still seems to be working though.

-

Well I've completely revised the fuel system. When I opened the filter up it was full of black flaky stuff which clearly wasn't good. Anyway I've made an in tank setup. Got another tank off a b6 which is definitely clean inside and put a flange on the bottom. Have the Walbro mounted inside now and is inside a 75mm pipe with a few holes drilled to hopefully eliminate fuel surge. Its a big pump and was a bugger to get it to fit. Took me a whole week of lunchtimes to make it all happen. I've put tank sealer in there too - just in case - because petrol has a way of finding pinholes in mediocre welds. And gave it my best metallic black rattle can paint job while I had it all off. Have a filter sock on pump inlet and a 10 micron filter before the injectors.

-

The pipe was just fusion welded to the flange on the inside. Have given it a decent weld today on both inside and outside and then got a jack under the sump and can lift the front wheel off the deck. So its pretty strong. But for peace of mind I'm going to look at making another one that actually attaches under the engine sump and has flexi hose to turbo.

-

Well I've just scared the bejesus out of myself. Was testing my boost control settings giving it some in top gear. And then my clutch started slipping so I got off the throttle. And then found myself going sideways. Wasn't my clutch slipping. My turbo sump had broken off and the turbo was draining all over the back wheel! If I tip bike about 10 degrees to the right I can see oil level on the sight glass so I think I shut it off in the nick of time. Didn't get oil pressure light and the oil temperature didn't skyrocket. Most annoying is that the sump broke at the turbo flange which I brought pre welded to the pipe because I didn't trust myself to not warp the flange! My two ugly welds further down held up just fine. Next time I'm welding the flange myself and grinding it flat again if need be!

-

Fuel filter is 100 micron. Fuel hose is 8mm ID with AN6 fittings. Fuel return to tank is m14 banjo which is not above the fuel level. I might start looking for a spare tank and start the fuel system again from the beginning!

-

Tested and finally have the boost under control Now to get electronic boost control functioning. I'm having a fueling issue thoughj. When the bike heats up in traffic if it has less than 10L of fuel in it it basically dies and won't start until it cools down a bit. At the same time the fuel pump makes some unhealthy noises! So I'm guessing it is something to do with the pump not dealing well with hot fuel (cavitating?). I know they talked about vapour lock on carbs but never heard of it on anything fuel injected. My fuel setup is as follows: Fuel leaves tank at rear, through a large filter and then walbro gsl392 fuel pump, large aluminium fuel rail then returns to tank via MAP referenced 4 bar regulator. When I fill that tank up it seems to be ok and likewise when moving at a reasonable speed so as to not heat up. Maybe I should put the pump in the tank or use a fuel cooler on the return line.

-

-

Perhaps - but its designed for a 2.3 litre saab so surely made to take quite a lot of exhaust flow

-

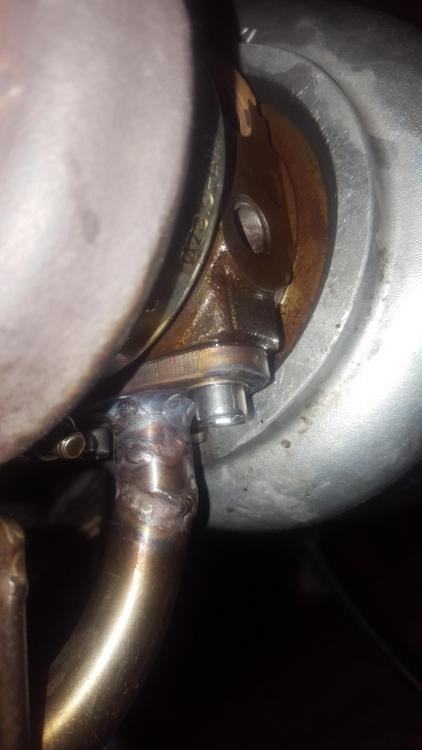

The pipe is the same size as the outlet dump pipe. I think 38mm OD 35mm ID but didn't measure. But I didn't realise til I took the photo that the hole for the pipe is a little smaller. Although it isn't as bad as that when I get a finger in so might be a trick of the camera. Either way I need to grind that out! I'm thinking I could possibly bring it out to the same 90 degree position but use a 90 degree bend off the collector to improve flow.