luke2152

Members-

Posts

117 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by luke2152

-

I'm still having problems with boost creep and its not the wastegate. Wastegate opens at correct pressure as near as I can measure. So I took it for a run with the wastegate completely removed and (apart from sounding like a spitfire and making the neighbours hate me) still gets into boost. 7.9 psi doing a long full throttle pull in 4th. With wastegate fitted (it is 7psi gate remember) it went all the way to 12 and I think it would have kept climbing (based on the datalog). Fortunately my AFR's are decent now. Clearly my wastegate pipe is not flowing enough to control boost. It exits at 90 degrees from the collector but looks difficult to make a smooth flowing pipe that doesn't interfere with the front wheel. Also could do with cleaning the inside of the welds up so make it a bit smoother inside. But is a 38mm gate big enough in pricipal for this setup. I would have thought so since saab seems to manage ok with an internal gate on this TD04.

-

When I say loosening - if I don't tighten them every 50 miles they will fall out. Its very annoying. I'm going to try oem ones and if that doesn't work drill and lockwire.

-

Bike is running great. Have put in couple of hundred miles on it. Mid range torque is great at 0.5bar boost. Keeping out of the top end revs til its fully run in and I have a decent AFR gauge. Think I have a bit of oil leaking from under alternator. Hard to tell exactly but I'm guessing there's a big o ring where the alternator goes into the crankcase? Also my header bolts keep coming loose. I used copper doughnut style gaskets. Will they settle down and stop coming loose after a few more heat cycles or should I use a pressed wire OEM type gasket.

-

Excellent info there Arttu. Especially little details like more rows on the low throttle positions. Today I slapped myself because I had been an idiot. I didn't realise the wastegate has ports for hoses on both sides of the diaphragm (I still have no idea why!) but I had my boost signal plumbed into the wrong side such that boost would hold it closed instead of push it open. That explains the big map reading. I briefly experimented with speed density alone - as you suggested it does not work well with small throttle openings. Back to Alpha N and set all of the AFR table likely to see boost quite rich to be on the safe side and then ran VE autotune through the revs with gradually increasing throttle openings. Then smoothed away out of place looking numbers of the new map. Now it runs really well and most importantly is not going lean in boost. I still haven't tuned full throttle at high revs or full boost but I feel like I'm getting somewhere at last.

-

Ok thats makes sense! Now when i use the table generator to make a base map it makes one with 15 - 170% TPS on the Y axis. Not sure why because you can't have more than 100% TPS. Is that correct or should i rescale it to max 100%. Do you have a VE table to get me roughly in the right area?

-

When using a secondary load table how do you tell it when to switch. Do you use table switching option and then switch at (for example) 110 kpa. Or is it done in one of the other settings. Tunerstudio is awesome but has so many different options!

-

I will check my wastegate setup. The ITB algorithm has a check box 'multiply by MAP'. I assumed this was for use on a boosted engine unless its just for an extra degree of control on an NA engine. Maybe I should just use speed density

-

Datalog was what told me the map was so high. I can't attach datalog on here though but have posted a question with datalog on the msextra forum: http://www.msextra.com/forums/viewtopic.php?f=101&t=66750&sid=8928f870c16ed61231d065f226369f4f Map sensor is this one: http://www.efi-parts.co.uk/index.php?productID=321 And selected 3 bar GM sensor on the software. It gives 95kpa when static. I also tried it with software set to 2 and 1 bar gm sensor and they gave 65kpa and 35kpa readings when static so its definitely not one of those. Btw the tiny digital boost gauge I mounted next to my clocks is about as useful as a potato and just shows random numbers

-

Have done a few moderate pulls and just as the turbo starts to kick in its hitting an artificial limiter. Datalog says it my overboost limiter set at 200kpa (absolute) but I've only been using 40% throttle and less than 6000rpm so that seems very implausable to me. Besides my wastegate should open at 7psi which is 145kpa. Before I blame the map sensor can someone confirm that one would not get anywhere near 200kpa (thats 15psi of boost!) without really giving it some?

-

-

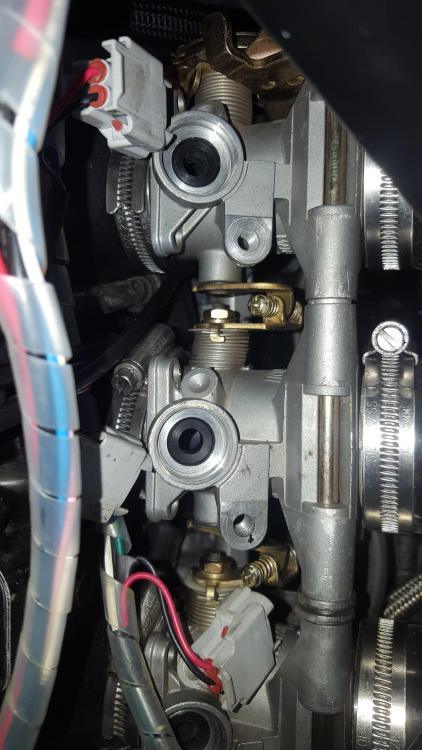

Those subaru denso injectors are designed to use 9mm ID and 16mm OD grommet. But the gsxr injectors use 13mm ID and 21mm OD grommet. So I was using the tapered but not stepped bit of the injector to hold down the big gsxr grommet which was never going to work under boost (easy to say in retrospect). Fortunately the gsxr throttle bodies have a 14mm bore below the 21mm one so I'm going to try and find some grommets in 9mm ID and 14mm OD. Otherwise I can drill the 14mm to 16 and just use subaru grommets.

-

Got it MOT'd today and finally on the road today! Not sure I'm a fan of that monstrous windscreen but it came with the bike. First ride taken relatively easy to make sure everything is holding together. Felt fucking awesome when it went into boost but then starting making odd ticking noise. Fortunately turned out it had just popped the injector o-ring out. Not quite sure how to deal with that - injector is from subaru wrx and throttle bodies from gsxr 600 - guess I'll have to make a washer that fits over the nozzle of the injector but holds the o-ring down. Also have a small oil leak which I can't identify - possibly from starter motor or alternator. Its collecting between those two.

-

Yes removed 1 more tooth from the timing wheel and gave the throttle bodies a sync and it starts perfect every time now. New battery helps too.

-

Yep I've got provision for -10 hose where the standard breather used to be and on the clutch cover too. So I'll do that. Getting hard to fit all this new plumbing!!

-

Been at it today sorting out the little details - ie. electrics for an mot so nearly ready for the road. Hopefully this time next week I can get it to make some boost! With the valve cover breather vented to atmo it does seem to have a lot of blowby - ie visible smoke. Is that normal on these engines. Should I do anything about it. With the air filter straight on the turbo it doesn't really give anywhere to vent it to on the no boost side of the inlet.

-

Been away overseas for a few weeks so ready to get a little more done. What I'd do for unlimited free time haha! Have ground another tooth off the trigger wheel, will see what that does

-

Happy to say that when I moved the temp sensor to the sump the temperature was a much happier (and more stable) 105 degrees or so. I knew the head was the hottest part but had no idea it was that much hotter. I put a chain on and took it out for a few laps of the carpark and and even with no tuning adjustments it felt quite well behaved. My latest problem is the trigger wheel. It started first time with a well charged battery but its a bastard to start with a half charged battery because at low cranking speeds its having trouble syncing. I'm thinking I might remove another tooth to make a 35-2 with a more pronounced gap. But I might pose that question to the megasquirt forum.

-

That was 150c - and measured off the sensor for my acewell digital dash (which might not be 100% accurate but shouldn't be far off). However I guess its measuring the cylinder head temp as much as the oil. Will try an measure at the sump. Whats an acceptable temperature for sump oil in traffic?

-

Have run it for about 20 minutes and it seems to be running very very hot. I'm talking 150 degrees (temp sensor in the bung in the side of the head) after 10 minutes of fast idling (about 2000rpm). Surely thats not normal? I tired running it with the garden hose spraying the oil cooler and it was still reading 125 degrees.

-

-

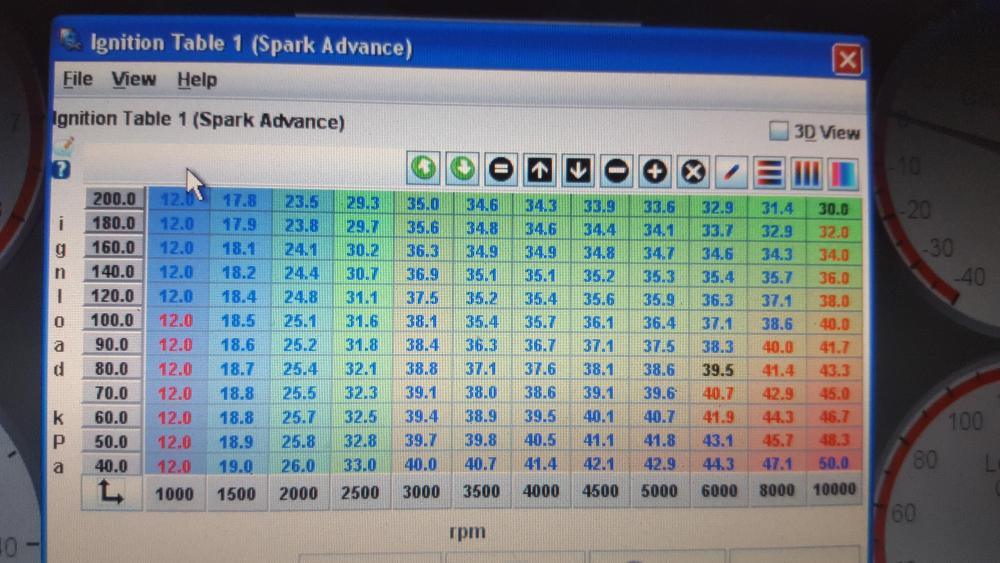

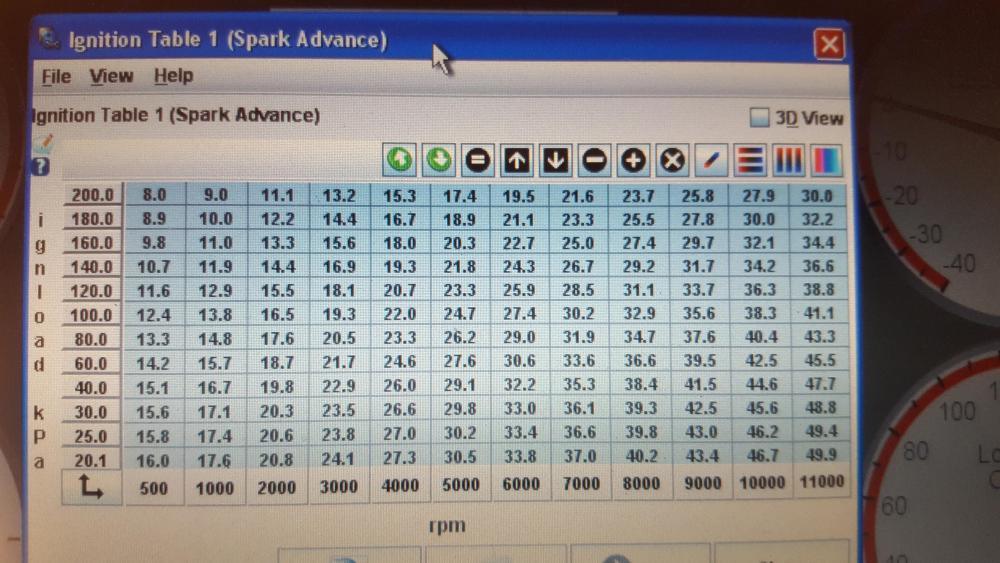

Yeah its all sloped across the table - I just put some plausible numbers on each corner smoothed the rest. Yes I can respace the rpm columns so I'll re do that for more low down resolution. So maybe around 45 degrees in the 3000-5000rpm across the board? 40 degrees at 100kpa @ 10000rpm and 30 degrees at 200kpa @ 10000rpm? Cranking ignores the table and uses fixed timing of my choosing (8 degrees?). Ign table is just map/rpm. I have the option of adding throttle position as well but think I'll keep it simple for now.

-

Was too busy to touch it for couple of months but back to it now. Engine is all back together with Busa pistons. Hoping to start it this week. Have made an ignition map - it's a slightly educated guess. Does it look like a reasonable starting point?

-

Is it alright to re-use the piston pin circlips? The last time I rebuilt a bike (many moons ago!) one of them failed and spelled disaster but I suspect it was due to me not seating it right rather than equipment failure. Also the o-rings on the cylinder studs and all the copper washers. I'm guessing they need replacing - should I be getting oem ones or just measure them up and finds something that fits. I hate dealing with main dealers...but don't want to be doing it twice!