-

Posts

349 -

Joined

-

Last visited

Reputation

159 ExcellentPersonal Information

-

Location

Dorset

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

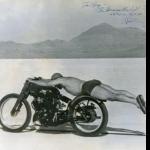

That’s a dot head on that motor in the picture. It’ll have a serious CR if that’s on the 1340 motor

-

That intake port looks big enough to swallow a child

-

Can you confirm the carbs you are running. If they’re from the Mk 1 bandit then 3 turns out is too much they should be 1 3/4 turns out. The Mk 2 carbs are 3 turns out. If you need 3 turns on the Mk 1 carbs then your problem is in the pilot circuit either it’s blocked or you need a bigger jet

- 16 replies

-

Going by the sprocket carrier the black one looks like a Bandit 12. But the adjuster are wrong.

-

Yes mate it should be blocked although I don’t know the material that the bung is made from.

-

I've run Bandit 12 wheels with standard discs on a WP 1100 front end. It needed a 2mm spacer (penny washer) on the calliper to fork mount for the callipers to run central.

-

Hi mate you’ll need a degree wheel, motion pro, APE amongst others do them. A dial gauge and mount machine mart and places like that. A piston stop again motion pro, APE et Al do these.

-

Ted M started following suzuki gt 750 kettle resto mod

-

Be very careful with the 81mm pistons and a dot head set up as the CR might be that high you can run diesel. I was going to do something similar but using Wiseco pistons but I checked the CR and found it to be in the region of 15:1. Also the piston crown was running very close to the cylinder head.

-

It’s an interesting one almost like the cam chain isn’t sitting on the crank sprocket properly. I would speak to @fatblokeonbanditas he has built a couple of dot head 1200s. What is the purpose of polishing the oil pump?

-

Afternoon oil cooled OSS land. I need a favour. I need to know the width of a B12 mk1 front wheel spindle and the width of a GSXR 1100 usd forks front wheel spindle (any model as long as they’re upside down forks). It’s a complicated tale but I’ve got 2 wheel spindles off a GSXR 1100 with usd forks (allegedly) both are the same width and both aren’t wide enough to go completely through both sides. Once I know the width of said wheel spindles no doubt it will throw up more questions. But at the moment it’s doing my head in. Many thanks in advance and a beer to the first one who gets the answer

-

@fatblokeonbanditmany thanks bud I’ve got it done now. I used 2 tyre levers with a little bit of pressure and it came off no problem. I had tried them before but I must have positioned them too far under the gear ring as it was flexing when I applied pressure. This time I positioned them just under the alternator gear ring and they came off no dramas.

-

If you’re going to do big bore and cams there’s no point in swapping as you can do the same to a B12 engine for the same outcome. It’ll also take a bigger bore (81 mm) before machining crankcases and using big blocks.

-

No worries mate I appreciated the reply anyway

-

No mate putting the clutch basket back in. I can’t believe I’ve been so stupid it even says in the Haynes manual to be careful. I’ve now got to strip it to find/check for the missing gear tooth (I found 2). I managed to get a complete clutch with good plates but the basket was damaged in transit hence the reason I need to remove the gear ring to swap it over.