Arttu

-

Posts

903 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Posts posted by Arttu

-

-

They should be quite good stuff. If you want to be extra sure get the ends measured and use genuine ARP bolts. They claim to have ARP 2000 bolts but I have heard here and there that they are fakes. Not sure what's the truth.

This year I have tuned a GSX-R1000 drag bike with those. No problems at 400hp level.

-

2

2

-

-

Well, if the ignition box reads removed sensor as "full throttle" then you won't notice anything else than maybe increased fuel consumption. And apparently this is the case usually since I haven't heard about any problems either.

But if the ignition box happens to read it as "closed throttle" when you are actually on full throttle then your pistons will probably notice it... I once measures timing curves from a SV650 which also has a TPS with carbs. In that case added timing on part throttle was pretty serious, 15-20 degrees if I recall correctly. So better to pay at least some attention when removing the sensor. For example leaving the sensor connected but hanging free on the wires might be a bad idea. -

For ignition side troubleshooting it's good to keep in mind that cylinders 1 & 4 and 2 & 3 share the same coil. So if another cylinder of the pair works then the problem can be only somewhere between the coil and spark plug.

Is that non-running cylinder completely dead or just "mostly dead"? Like if you put a new plug there will it get any black soot or does it stay completely bright? Or can you notice any heat on the exhaust runner?

-

1

1

-

-

9 hours ago, TLRS said:

Any overlap in valve timing? Afaik normal for n/a application but less suitable for boost, at least I think I read it somewhere?!

I also thought it was good to have cams that work early and spool turbo early. Then tune the rest of the graph with boost?

Pretty much all bike cams have some overlap. Effect of overlap on boosted engines depends a lot on setup. If the turbo is sized properly so that exhaust pressure doesn't get much higher the overlap works pretty much like on N/A engine. So some overlap is beneficial. Low / no overlap can be good if exhaust pressure is high like on many stock(ish) turbo cars.

-

1

1

-

-

11 hours ago, rerb said:

Wow, glad to know. Whats limiting me is probably the afr which is fairly rich, but my power tapers off far sooner than the other charts of stock cams show. Next season I'll spice up the tune a little and maybe turn down the meth and see what that nets me. I had some issues with the APE head nuts coming loosing causing the head gasket to shimmy around a little, I'll probably pop the head off and inspect too. I have busa pistons but also shaved the cylinder a mm for extra compression so it's still fairly high.

Under 11 AFR numbers start to be at the region where you may get rich misfires. And since misfires cause false lean reading on lambda you might be even richer in reality. So yes, tuning it a bit leaner would be also my first suggestion. Also too high water/methanol injection rate can cause misfires or just power drop in less severe case.

-

I have never done back to back comparison where only the cams were changed. But I have tuned various oil cooled turbo build, with Bandit cams, GSX-R cams and aftermarket cams. By this far I haven't seen any clear connection between the cams and power curve shapes, or power numbers. Which is slightly odd since the cams should make difference and I have seen that also in real life with some other engines. I guess that other variables in these oil cooled builds just have been more significant.

A couple of examples:

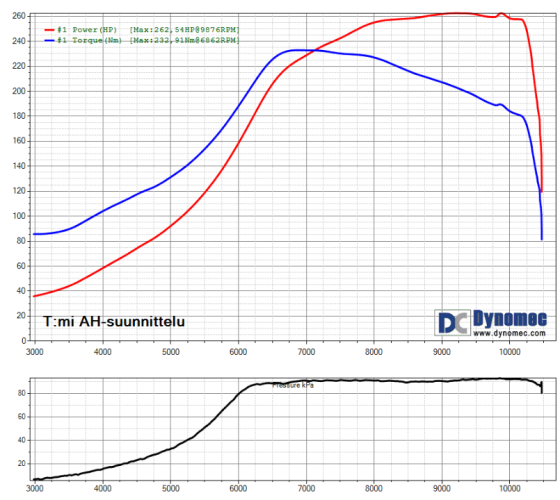

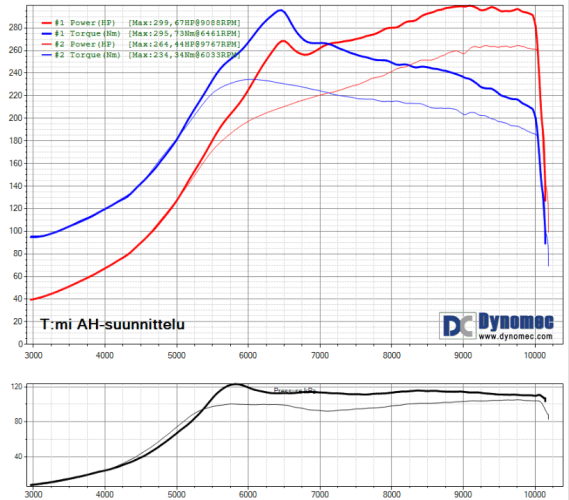

Bone stock B12 engine, never opened as far as I know. Mitsu TD05 turbo, E85 fuel, 0.9bar boost.

GSX-R1100, 1216cc turbo pistons, ported head etc. Some other Mitsu TD05 variant, pump gasoline, approx 1.0 and 1.2 bar boost.

Funnily that stock B12 engine has been hard to beat in boost / power ratio

I guess the main reason is higher compression ratio and better combustion chamber shape compared to other builds.

I guess the main reason is higher compression ratio and better combustion chamber shape compared to other builds.

Any way, if you now get around 240hp at 19psi I think the cams aren't the first thing on the improvements list.

-

1

1

-

-

Have you tried to swap #2 and #3 plug wires already? That should cover pretty much all the electrical faults. And that starting spray into non-running cylinder carb throat is worth of trying too if you haven't done that.

I think at this point all remote diagnosis starts to be pretty much blind guessing. But sometimes that can help too...

-

It's for igintion timing. Most likely it adds timing for low throttle. Improves fuel efficiency and maybe emissions too.

I guess the ignition box is designed so that it reads full throttle position if the sesnor is disconnected and therefore uses safer full throttle timing. But if I would use such system without the sesnor I would ensure that by connecting the signal wire to 5V wire. Or leaving the sensor there and locking it to full throttle position.-

1

1

-

-

Sounds like a mystery indeed...

- Even compression and sucking air through the carb are quite sure indicators that all is good with valvetrain and piston/cylinder.

- Trying different carb sets and having a wet plug pretty much outrule fuel side problems.

- Having spark and trying different coil cover a good part of potential ignition issues too.

Based on symptoms I would still look on the ignition side. I guess you have changed the plugs too? And plug wire / boot wth coil? Even if the plug gives good spark outside of the engine it can fail under the compression.

For fuel side you could still try spraying starting spray into carb inlet when the engine is running and see if the cylinder gets alive. Bad enough air leak could possibly prevent firing even if the carb is feeding fuel.

Out-of-box idea: Have you checked that the exhaust header isn't blocked?

-

-

In case of the EFE the restriction is done by the cams.

-

3

3

-

-

Two pickups version is older one and it's used with a trigger wheel that has only one tooth. And naturally the ignition control unit must be compatible too.

As far as I know you can use the "two pickups" plate on newer bike and connect only one of the pickups. But I would verify carefully that the pickup is at the exact same location to keep the ignition timing unaffected.-

1

1

-

-

For 260hp stock gen2 Busa rods should be perfectly fine, I think.

-

40 minutes ago, Ådne95 said:

Thanks a lot Arttu! Kent JP3 cams have an equivalent of .351" lift then

you don't happen to have any experience with those cams ?

you don't happen to have any experience with those cams ?

Unfortunately no. I have been using only stock cams except one unlucky experiment with Web cams

-

1

1

-

-

Rocker ratio is 1.6:1 according my notes...

-

12 hours ago, Breadman said:

I have been trying to get the injector deadtime as accurate as possible for the Subaru injectors. Looking online has given me some varying figures but none of the figures quoted were taken at the 13.2volts that Megasquirt 2 uses as a baseline.

Im all new to this ecu programming and whilst a ballpark figure will get your engine running, it just makes sense to find out the exact deadtime for my ecu and injectors (time it takes for the injector to open and close when its told to).

YouTube to the rescue and a solution.

I started doing what I was told in the video.....and.... the fuel rail o-ring on the injector split. Swapped the injector for another one and then the alternator stopped working so gotta fix that before I can start the test again.

The A/F meter has also lost its 12v power from the ecu and I cant understand why. It works and functions fine when connected to an alternative power source but it would be nice to solve the puzzle.

I assume you are firing the injectors with the test mode at different pulse widths and measuring the resulting flow? That's the correct way to determine the dead time. Just be careful that the battery voltage stays stable during testing. Your injectors are large enough that the deadtime settings make some noticeable difference. But still small enough that it isn't absolutely critical to get it exactly correct. 2200cc/min injectors on a 1000cc start to be slightly tricky

There is a fuse inside the ECU for the lambda sensor feed. If you have accidentally short circuited the supply wire the fuse might be blown.

-

I was recently building a plenum and charge piping for a GSX-R1000, aiming for 400-500hp. Space was tight so I was using 50mm pipe but was a bit concerned if it would cause restriction. I found a quite nice web calculator where you can insert pipe diameters, lengths, turns and air flow figures and it calculated the pressure drop. If I recall correctly a 500mm long 50mm dia pipe with a couple of 90° turns resulted about 0.1 bar drop at air flow that a 1000cc engine takes at 12000 rpm.

So, I built that setup with 50mm pipe. Worked ok although total pressure drop from turbo outlet to the plenum was a bit higher than I was hoping, around 0.1 bar at full power. But there was also an intercooler cell in between so I have no idea how much drop the pipe alone caused.

In short I would say that 2" is probably fine unless you have long piping with plenty of turns. But on the other hand using bigger size shouldn't hurt anything either. So if you are building new one and you have space then bigger might be safer choice.

-

1

1

-

-

I think larger throttle bodies with freely flowing air filter and good exhaust should give some noticeable improvement on power. At least my 1074cc GSX1100E gained about 15hp back in days when I switched to EFI and replaced the exhaust with more freely flowing one. And that was with relatively small 34mm TBs and very basic DIY 4-1 exhaust.

Beyond that it starts to get more expensive or difficult, I think. Normal tricks are increasing displacement, upping the compression, porting the head, hotter cams and so on. As you know. All these tend to cost quite a lot or at least require some knowledge and skills for DIY work. I'm not aware of any special bottlenecks in this engine that could be easily improved for significant gains. Or well, cam timing is worth of checking and adjusting if needed. Factory tolerances seem to be pretty bad so you may get quite nice improvement just by setting them to nominal stock values.

I would guess that some mild performance cams would give noticeable improvement even without head porting. But it's very subjective question if that is worth of cost. If your cylinders and pistons are in less perfect shape some big bore pistons with higher compression would be quite obvious solution. They should give results no matter what other modifications you do.

I don't see any easy ways to reduce engine weight. Besides that sprocket cover and possibly some other similar parts. Most of the weight is in the crank, cases, head and other similar parts. In theory you can probably shave some material off from here and there without significant drawbacks but the weight saving will be very small, I think. Or you can spend a fortune for fancy lighter parts (mostly custom made) and get more noticeable reduction. But even then it will be a heavy boat anchor in the end

-

I recommend taking also MAP pressure signal from between the throttles and head. Depending your control strategy you could use the plenum pressure too but based on my experience that's often more problematic option.

-

Yep, for that purpose all of them should work. Personally I have used MRE and MTC "snowflake" on my GSX, didn't notice any difference between them.

-

1

1

-

-

If you use it only for preventing slip they all should work pretty much the same. For drag race use where you want controlled slip on launch a "multistage" version would provide more adjustability.

-

2

2

-

-

Sounds very much like you have some block on intake side of the pump. I once chased similar problem for quite long time before finding a displaced o-ring inside the tank side quick coupling.

-

3 hours ago, TLRS said:

A reed valve to bypass inlet drag of the turbo is also really cool. Would it work with fuel injection though? Basically it creates a second air inlet. Depends on what sensors the FI relies maybe?

No problem with typical aftermarket EFI systems. A mass air flow based system could be a problem but these are very rare on bikes.

I guess that benefits of a priority breather valve depends a lot on turbo sizing and boost piping length. I have thought about trying it but when analyzing my data logs it seems that there isn't much need for it. Intake air pressure goes very close to ambient pressure right away when opening the throttle. So logically thinking the priority valve can't improve the resonse much. Maybe with smaller turbo which restricts air flow more it could be helpful.

-

1

1

-

-

Haven't personally tried antilag on any engine yet. But I don't think I would like to use it on streets. Like mentioned it's pretty hard on all exhaust side parts and quite noisy too.

There are few different ways to implement the antilag function. Without electronic throttle an external fresh air valve and plumbing is needed to feed air to exhaust manifold. Simultaneously extra fuel is added through the injectors and ignition timing is retarded. With electronic throttle the external air isn't needed but the throttle is just kept open during engine braking. Apparently electronic throttle approach is more effective and offers better adjustability for power delivery. In any case pretty good engine management and tuning is needed for proper functionality and good drivability.

Compression ratio.

in Forced Induction

Posted

I think gen1 Hayabusa has about 11:1 compression ratio. But what's the point of your question? When you fit the Busa pistons into a Bandit engine the resulting compression ratio will be something completely else any ways.