-

Posts

235 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Posts posted by Lachie04

-

-

I have a Dyna 2000 and set it the same as you iirc manual says to set@36-35

Anyhow the second time I set it up on a different tacho found the read revs were doubled not sure what was going on there so ended up taking a feed straight from coil to the tacho which sorted the double rev reading

-

@ 11.3:1 and using high octane fuels (pump) only made my plugs blacken quicker went off it back to standard pump fuel (non European) fuel, never noticed a difference IMO

-

"The R DOT heads have steeper inlets, appr. 15 mm higher than the F DOT heads."

Both DOT heads R and F have the same inlet tracks the only difference is the cams lift & duration

98 and on model gsxf the mark 2 teapot went back to the standard long stroke head

set up

-

Have heard you use a hot air gun on the plastic clips to ease them out of the way without breaking them

-

-

I have been struggling with the same question since putting a bigger motor in the bike and having the bike stutter down the track straight (tbh it may have been a loose spark plug)

According to calculation 140 hp would require 11.5 gph (100hp would equate to 8.5 gph)

Therefore theoretically if your fuel system can flow better then 12.5 ml/s (12gph) then you should be able to sustain a high speed run

This is all theoretical and can't be relied upon to be sure so many variables

The answer is really suck it and see

-

-

-

Just to throw span and two cents in

the idea of a six speed box is to gaining closer ratios not overall speed

I would have calculated the gearing against max torque figure as that is where the most benefit is made IMO (but then I may have had a beer or two)

otherwise you're just changing gear 10k sooner and more often just to get to a top speedIdea of close ratio box is to get better drive out of a greater variety of corners

-

-

-

You may find you will need to compress the spring spacer which sits atop the spring if planning to do it as per the vid.

have seen a couple of different ways to do this either undo the bottom bolt which holds the damper and pull out the whole damper spring and fork bolt in one or compress the spacer and disconnect the fork bolt (as per the Video). To be fair don't know how difficult that is on these but was a bitch making something to fit the TLS forks, that I did.

You need a tool or fashion one to ram home the seal and do not forget anything (ask me how I know).

Do a you tube search to get some ideas easy to find

-

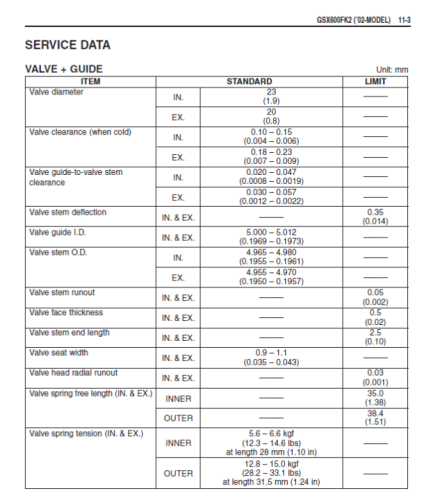

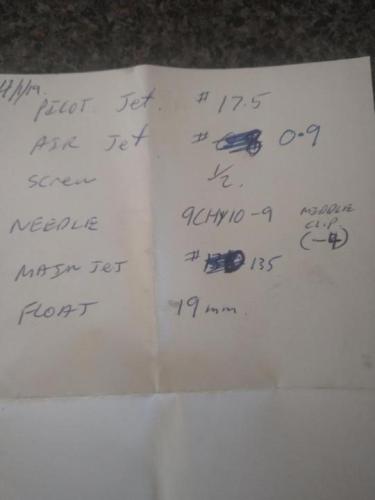

I dug out final jeting solution for mine after a few rounds on the Dyno it was border line 132.5 - 135 on the main jet anything to much bigger would over rich the engine at WOT I did change the air jet to 09 just to play round with some slow speed richness but don't think it was really m necessary and changed pilot jets but main jet def start round 130 up

-

1

1

-

-

I had 38's on my 816 Dot head motor and loved them gave around 17k/l + (40+ mog) normal riding and were pretty good. Loved the fine control in mid range and for quick take off a little rev to around 2000 to get the air moving would pull sensationally I always thought they were a little big but they were destined for a bigger engine in the end so didn't mind . If just building a 750 then I would probably go 36's but they will work

-

2

2

-

-

Hopefully not a bad move to post this link but it's a good write up

Hopefully not a bad move to post this link but it's a good write up

https://planetbuhs.net/motorcycling/bandit-hella-mod

He flipped the plates but I didn't it didn't need to also I didn't seal the back like he did and have ridden this in absolute down pours and is now 18 months on with no I'll effects the lamps are totally sealed and water proof in their own.

If doing this the one bit of advice "do not get that grey shit sealant anywhere"

I have a few photos of my own

-

10 hours ago, beardo said:

Anyone happen to know if the Mk1 fairing will bolt on to the K Bandits? The projector lamps on the K-S are horrible. I have an N top clamp so maybe I'll just remove the fairing. Need to do something soon for light. It's a must. It's still dark when I leave for work, otherwise I wouldn't care.

20w led projector lamps absolutely fantastic upgrade

-

My suggestion to use the 89 750 input shaft was so you can use the 1100 clutch basket instead of the oversize 750 unit. Also suggested by Creg-ny-baa, However as the 1100 clutch stack is taller you would probably need to use push rod clutch as doubt the 750 actuator could work or be modified (IDK never played with them you would have to play with that).

An alternative to drilling the shaft, as has been done (from the stories on here), the TEapot input shaft already has these.

Differences between teapot and R is first and Sixth gear ratios.

So if you're not comfy with possible contact between clutch outer basket and crank the only solution is to use later model transmission.

On my 1052 into 750 cases the No3 rod cap bolts hits the oil web I ended up shaving 2.2mm off the web but this is only one reciprocating part not two as in yours.

BTW why I used the 5 speed from the GXSF was mainly that the gears would have needed to be replaced and I couldn't be shagged and its mainly a road bike.

-

2

2

-

-

Swap the input shaft for a 89+ GSXF 750 unit ??? Chamfer nut seen that on big stroke cranks??

-

1

1

-

-

Why not just use the slabby clutch has more plates and contact surface than the 750

http://oldskoolsuzuki.info/archives/tag/clutch

750 cases 1052 crank and clutch but in this case fitted to 91 GSXF1100 gearbox (my choice)

Btw you've sorted the clutch actuation out I guess ??

-

3

3

-

-

1 hour ago, no class said:

I knew 3 guys that did this 6 speed swap way back when it was cool…..and all of them had 2nd gear failures ….. fucking waste of time for the agrovation.

Yep

-

There should not be any movement either longitudinally or laterally with the drive or driven shafts.

Each have pressed on bearings (tight) which in turn are secured with grooved C clips(?) to prevent any slippage between case and bearing

regardless of if a sprocket is or not then fitted

Any movement would accelerate gear wear check bearings to make sure they are not worn in the race which may induce end float

-

IDK but seems to be the same issue as this

-

1

1

-

-

The. Slide guide itself may be worn I replaced a set in a bst36 set once. From memory they were a tight fit.

Check this site

https://store.moto-lab.com/articles/bst33-slide-guide-wear-indicators

Although a different area may be related the guys that run this site very knowledgeable maybe have a chat with them for advice

-

13 hours ago, fatblokeonbandit said:

Thats it shipmate, spot on. Thanks.... I like that, just hope ive got enough paint in the tin I found..??

Yeah I also filled in the underside black to make the frame pop a bit and thinking paint the seat support you built white to blend it into the frame

Question about DYNA 2000

in Oil Cooled

Posted

Yep that's right idk what the issue was with mine though