-

Posts

2,584 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Posts posted by davecara

-

-

1 hour ago, clivegto said:

Have you seen the price of shells mate they're not cheap.

I know that’s why I’m trying to get all the bits on the cheap

Hopefully there’s an 1127 bottom end going that I can trade bits for and I’ll just give that a refresh. Fingers crossed all the bearings will be within spec

-

50 minutes ago, no class said:

If you go the 1052 bottom end route..... either way the case needs boring to fit the cylinders. I would source a b12 block as it will be better than the 1127 for larger bore .

I would prefer not to pull my 1052 to bits to be honest but it comes down to pennies at the end of the day!

I've rather foolishly set myself a bit of a challenge to see how cheaply I can stick a turbo motor together!! I've got the run of a decent machine shop and loads of bits to trade/swap so I'll see what I can find. Got 1127 barrels, turbo headers and busa pistons and a load of other odds and sods off a mate, there may be an 1127 bottom end coming my way too that needs a rebuild so fingers crossed if I can get that I'll keep the 1052 in one piece

Then it'll just be shells and gaskets to pay proper money for!

Then it'll just be shells and gaskets to pay proper money for!

-

Are all the heads interchangeable too?

So far I’m looking at a set of 1127 barrels rebored to suit my pistons; then either build up a bitsa 1127 bottom end or use my 1052 engine

-

On 28/12/2017 at 6:07 AM, george 1100 said:

In saying all of this, did you guys aligning your rear wheel to the front wheel first. I found that in order for the wheels to align the rear needs to move to the left about 8mm. The most the swingarm could move left was 4mm by backing off the axle adjusting nut. This makes chain alignment even worse

As @MeanBean49said, I made tophats to put the swingarm slightly offset to centralise the wheel to the frame. Using an oil cooled engine too so I'm unsure what the alignment would be like with a proper EF engine. I mustve struck lucky with my wheel swingarm combo as theres wasn't any need for machining on the wheel. Just a few spacers to knockup

-

1

1

-

-

I've got a mint tinkered with T3 off my old shonky sierra but the exhaust housing went AWOL when I lent it to someone for mocking up

Also the flange that's on these headers is only 2mm thick and bodged on to boot. I'll make one out of some 8mm plate I've got kicking about. Need to find a plenum now!

-

Brilliant thanks @Captain Chaosand @clivegto

Looks like this will be a goer then once I’ve stuck a new flange on it and found a T3 turbine housing!

-

Anyone have the measurements to hand? Nowhere near the bike for a few days and I’ve been given some turbo headers but I’ve no idea what they’re off!

-

1

1

-

-

I’ve had a mooch through the archives and can’t really find anything definitive;

Whats interchangeable between the two 1100 engines?

I’m currently mooching and swapping to get bits to put a turbo engine together, I’ve got 1127 barrels and busa pistons and another member in here has gifted me a load of bits and bobs but I don’t want to jump into a building the engine without knowing what’ll work and what won’t!

Will an 1127 crank go into 1052 cases or 750 cases for that matter? Would I need to match the clutch baskets to whatever crank I use?

I know I’m best finding a complete 1127 to rebuild but I haven’t got 500 quid kicking about!

-

16 minutes ago, Duckndive said:

1196cc in an EFE is 76mm bore ....Busa 81mm pistons gives you circa 1345cc and needs a big block or re-linered stock block

I’m running an oil cooled 1052 engine in my EFE, can’t afford a proper engine for it!

im currently scrounging 1127 bits though so might end up 1216 yet!

-

The EFi may well end up on my EFE once Iget my head round it. That'll be 1196cc with these pistons and a Garret T3 hanging off the front

-

1

1

-

-

On 13/09/2017 at 2:08 PM, davecara said:

I'm running a K8 1000 arm in my EF with a 1052 engine so our measurements should be pretty similar.

im hoping to make some progress on mine over the next week so I'll keep an eye on this thread!

Just to add to this,

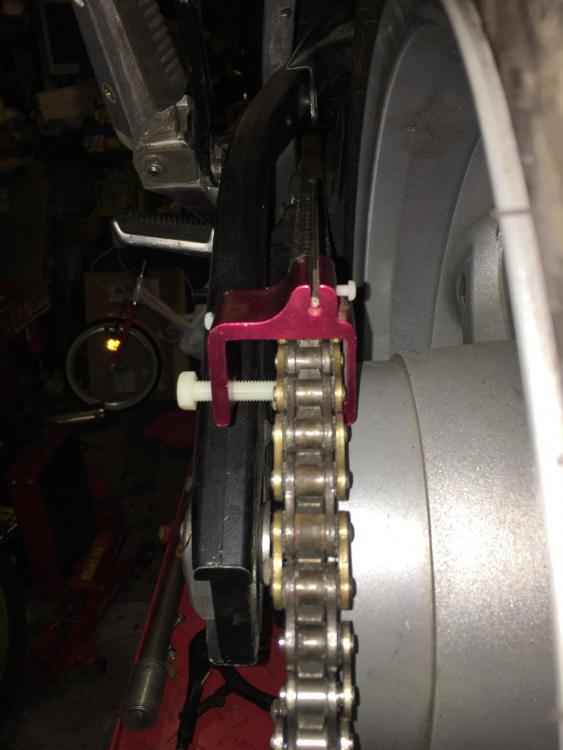

K8 swingarm, Gen2 busa wheel, 1052 engine.

Flipped the rear sprocket and used a 6mm spacer behind the front sprocket, 530 chain. All lines up perfect

-

13 hours ago, slingy1157 said:

Got my gsxr750 short stroke rods bronze sleeved to fit zx10 pistons. No dramas woth it

Nice one Jack, hows your 750 going? Still havent got my EFi'd 750 running yet. Kept losing sync with the crank pulse, it was down to wiring and 3 duff batteries in the end. Gonna get back on with it in the new year

-

27 minutes ago, Paulm said:

If you’ve gotta sleeve the rods you may as well just buy some Gen1 pistons and put them in.

Not if the pistons and sleeving are free!

-

16 minutes ago, nlovien said:

can also confirm on fitting bronze sleeves into small ends - done this before with no issues - for sure its got to be done by an experienced shop = tight accuracy tolerances

Warm rods, chilled bronze bushes then ream out to correct size once they're pressed in I reckon

-

33 minutes ago, Gixer1460 said:

Can't see any reason for not sleeving the rods if machining is FOC as an option.

That’s the kind of positivity I need!

off to do some research on putting 1127 barrels on my 1052 bottom end....

-

On 12/20/2017 at 8:41 AM, Paulm said:

Got Gen2 in mine but we did change the Conrods to Falcons as well

,

,

It’ll defeat the object of getting free pistons if I’ve got to buy rods

is sleeving the little end of the rods a viable option?

-

It’ll be an oil boiler of some description.

If the Gen2 pistons can be taken out to 20mm and still give the same CR as a Gen1 then I’m sorted I think. I can get some Gen2 for practically free and machining done FOC too

-

Been done to death I’m sure but can see anything in the search so...

whats the script with busa pistons? Are Gen2 pistons any good to use? Or is the wrist pin the wrong diameter?

-

25 minutes ago, fatblokeonbandit said:

where the fek is event city????

Salford if I'm not mistaken

I'll be up for that

-

I'll be up for sticking my Efelump on the stand.

-

1

1

-

-

@Ben SlabbyHad a fag packet sketch that did the trick for me

-

Search further down the forum, I'm using a MK2 bandit loom with a chinky ignition switch.

Benslabby stuck a working diagram up for me, I unpinned the plug into the cdi and soldered a 100ohm resistor onto the side of the plug and grounded that to the battery and left the loom intact

-

Sumps

in Oil Cooled

1 hour ago, Cheeky4648 said:Would a 750f teapot 1993 -95 fit? They seem to have the deep area right in the middle and front exit oil lines. Don't know much about them swapping to other engines though.

Yeah it should do so long as I have the correct pick up with it.

have you got one you want to part with?

-

Sumps

in Oil Cooled

Maybe flatter is the wrong wording, I want to tuck my exhaust up a bit closer to the sump and the banjos on the bottom of mine are stopping that with the exhaust I’m using.

I’ve just bought a new oil cooler set up that’s got lines for a front oiling sump.

hoping to kill 2 birds with one stone here and spend the cash I would use for banjo fittings on a sump and pick up

Garrett T3 turbine housing compatibility?

in Forced Induction

Posted · Edited by davecara

I've got a not long rebuild Garrett T3 that I took off my old shonky sierra before it died of tinworm, The turbine housing is missing off it though and the standard sierra cos housing is internally gated. Anyone know what else used the T3 that I could pinch an externally gated housing off?

I would stay internally gated but I don't think theres room for the wastegate actuator as its a bit tight down there (ooer!)

Pic for OSS content