-

Posts

195 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by majortom4

-

Ok thanks for that.

-

From what I can gather, the one pipe on the side on its own is fuel in, bottom 2 on the side with 3 are fuel out, top one on the side with 3 is air pressure pipe and one underneath is fuel return. o whilst on subject of fuel return, can I use the standard overflow pipe from the tank as a return or will that not work?

-

ok so after a lot of searching I found out that the bolt is a M12 with 1.25mm pitch...... Pretty tricky to find an elbow with that thread so had to buy an adaptor to change thread then an elbow off that........ just wondering, with the fuel pressure gauge should it be off an inline adaptor or can it be on its own pipe off the pressure regulator? (I have the malpassi pressure regulator with 1 in and 2 out with drain and pressure check pipe)

-

Ok no worries cheers. going to take the bolt to a shop tomorrow and try and get some hose and fittings to make myself a return to there. Will get a facet fuel pump and put that inline as well to help with the return.

-

@clivegto what fitting are you using for that oil return??? Where did you get it from as I'd love to get myself one.

-

So a normal 'facet fuel pump' will be ok rather than having to buy a specific oil pump/oil scavenge pump???

-

Hopefully turbo will be here Monday so I can start the manifold planning, get the correct size for plenum pipe and get the plenum welded.

-

ok awesome. What pump do you use? Struggling to find out at the moment. will probably have to get some more piping if I'm going to run it to there. And some more adapters. I like it there tho as its out of the way i am putting in a 0.5mm restriction in my feed just after the banjo as well.

-

cheers Clivegto. I just saw this before after reading about your build on the old site. Love it by the way! do you have a scavenge pump for the oil return to there or just gravity?

-

ok will do. Thanks

-

O and didn't have the banjo bit so drilled and threaded the bolt from the oil bit, used an old break banjo and threaded it to fit my oil line, and drilled the inside of the banjo out to the same size as my oil line.

-

hmmmmm ok fair enough. Will buy a 90 degree connector for my hose and drill a hole in the side casing. Is there any nice way of doing it or is it just a matter of find a spot and get drilling??

-

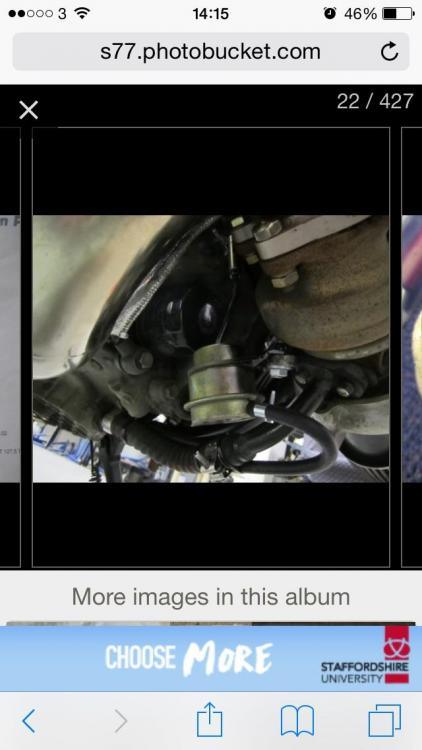

Ok. What if I drilled the sump like this and put it there with a non return valve?? Would that work??

-

Hey guys. Could someone please help me out with where to run my oil feed and return for the turbo. Pictures would be awesome of where ppl have for this. Trying to find somewhere with as little modification and messing as possible. thanks in advance :-)

-

hmmmmm decisions decisions. I'll see how I feel tomorrow weather I want to file out some more holes or not haha. Looking forward to 200hp :-) cheers dude

-

Hmmmmm what to do what to do.... well To put a bit of pipe on would mean it being 70mm OD to fill the whole as its like an egg (the same as the air box) and the carbs are 60mm...... Soooo think I'll have to re-make the faceplate with 60mm holes to put some pipe in then silicone hose from plenum to carbs. At least then I don't have to worry. But hell it was hard work making those holes in 3m aluminium with a drill and a file.......

-

ooo ok. Is yours the same as mine with the rubbers sitting inside the plenum??

-

hmmmmm i see what you mean. I did ask this question before weather I should use stock rubbers or put pipe on with clamps and someone said stock rubbers would be ok. I can see it being a problem further down the line. Luckily I have just enough aluminium left to make another bit for the front to weld pipes onto.

-

what do you mean by sealed to the box?? they are the stock rubbers and fit really nice and snug with the overlap inside and outside, can finger the holes to make sure they are seated properly.

-

so for todays antics! I got my 3mm aluminium sheet through today so made my plenum. Just need to get it welded up now.

-

Cheers slingy, iv read the same as well. Reading about MTX-L and it seems to be a solid choice, not heard many bad things about it and the price is reasonable as well. Can anyone shed light on what a data logger is/does and price and if it is necessary??? (Yes yes I know it logs data) guessing data from the AFM? Awaiting for Santa to come with all my goodies then can get this show on the road!

-

I am looking for the whole shebang for the AFR gauge, controller, sensor etc. was just looking for personal opinions. Yer I think I may be using a bracket to hold the turbo up and probably a scavenge pump. if not using the down pipes I was looking at using 2mm thick mild steel tubing for the manifold. Would that be suitable?