IhmeJanneFIN

Members-

Posts

49 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by IhmeJanneFIN

-

Good to know Arttu. I have also been thinking smart way to control those vanes and it would involve some type of vane opening system for cruising and idle to not cause high exhaust pressure. Adjusting the vane position to just at the tip of spooling one change, but sounds sketsy. Might give a try on my SV build for vnt turbo, as there is more room for turbo as no side fairings. But before this goes totally offtopic, about my original question of using gen2 busa parts, anyone has any input on that?

-

I am also thinking it will be too small for 1216cc engine. I have two of those reed valves on the back of the plenum an they are quite big. I know there is somekind of turboshop in city next to my town, might be worth a visit at somepoint. My current engine is actually only 5mm lower than a stock 1127 as I have 12mm of spacer under the current 748 block, so not that much will change I hope, but time will tell when I begin the engine build.

-

Well, when driving around 100 km/h 6th gear on highway, it is on the brink of spooling at the moment at 3000rpm. Twist to full throttle and under 1 sec there is full boost on the gauge and off we go. Turbo is somewhat special as it's from a Mercedes diesel engine with 3 bolt pattern, so there is no bigger version of that specific turbo family that I can found. Only one with the same bolt pattern is GT2256V, also from a diesel merc, but is fysically bigger also and with variable geometry so might melt the vnt system on petrol engine. I am tempted to try as the idea of vnt sounds fun with low spooling and big flow at high rpm. From my current turbo I may need to build a hybrid with custom wheels but sounds expensive and not worth the money. Been thinking of using some maxpeeding GT2860 or similar. GT2252/GT2256 would possibly be better, but I can find only expensive oem garretts and not cheap aftermarket versions. As this is a street build, I rather have the low rpm spool as opposed to max power at redline where it cannot never be used on public roads.

-

Std used gen2 rods and pistons I could find around 250-300€ with postage on flebay. Bare gen2 pistons for around 150€. Some guy here in Finland is selling unused gen2 pistons with rings for 250€. Has multiple sets to sell. Maxspeeding rods for gen2 cost around 400€ with postage. About the same for 1100/1200 oil boiler with 20mm piston pin. New mtc 10:1 turbo pistons with 20mm pin, to get them here in Finland would cost around 800€. So, by quick math; Gen2 used parts would cost around 300€ and would be ok for around 250hp? Gen2 NEW pistons and gen2 maxpeedingrods would be around 650€. Pistons good for around 300hp?? Conrods advertised to be 600-800hp, but I am skeptical of that. Carillos would cost me a liver and an arm, so they are out off the question. New MTC turbo pistons and oil boiler dedicated maxpeeding conrods would be around 1200€. Would definately be good for 300 hp. So going busa gen2 parts it would be about half the price, even with beefier maxpeedingrods. Spacer I can make myself, have done already multiple spacers with my handtools in my garage. Took some time, but managed to make them . I am bit spectical if the MTC 10:1 compression would be too high and still need to run a spacer plate to lower comp to around 8.5:1. That's what I currently have in my Frankenstein 988cc and it's got good torque off boost. I do have the primary breather valves* on the plenum, so the engine breathes through those valves when not on boost so it definately helps with the off boost driving. (*The primary breather valves are big 2-stroke reed valves, so when there is vacuum in the engine, it draws air through them and not all the way through turbo and boost piping. But when plenum sees positive pressure they automatically seal closed as in 2-stroke engine. Seem to work great as with my first engine, turbo started to spool around 1000 rpm lower that without the reeds on plenum.)

-

That is the idea at the moment, but it may be sometime before that may happen. Also on my gsxf sleeper build, space is a luxury (only few mm on turbo cold side to fairings), so there is only barely room for current turbo, let alone to a bigger one capable to around 300hp. Current on is GT2052 of a diesel merc, so quite small and smaller than usual GT2052 AR numbers, so very quick to spool, but might be a bit restrictive on high rpm. But hey, it's a streed build so I like the low spool. It is barely run at high rpm and it's got an 40mm external wastegate, so exhaust pressure isn't a problem what I have measured pre turbo exhaust pressure.

-

Hi all, i thought of starting a new thread, but I may just ask this here. Been reading through different 1216cc turbo build threads, and on almost everyone is mentioned gen1 pistons and conrods are the way to go on a budget, but I would like to ask though. Has anyone used gen2 busa conrods and pistons on 1216cc turbo build with success on about 250-300hp range builds? I know the gen2 busa pistons and rods are "weaker" as they use 18mm piston pins as opposed to 20mm on gen1 busa pistons. I also know the rods are same length, but gen2 has thinner bolts on the big end and smaller small end to accomodate the gen2 piston. Also the gen2 busa engine is stroked +2 mm from gen1, but block height is the same on both as they can be swapped around. I looked through Wössners catalog and the pistons compression height differs. Both pistons are 13.5:1 compression ratio; Gen1 compression height: 25,25mm Gen2 compression height: 24,00mm So there seems to be 1,25mm difference in compression height to make room in the busa to add 2mm of stroke in the same available space? Hypotetically thinking, would this mean, that using gen2 busa parts on a 1216cc build, there wouldn't be need for as thick spacer under the block as opposed to using gen1 busa parts? I am asking as gen1 busa parts are highly sought after, so are beginning to be hard to find and costly. But gen2 busa pistons and rods are plenty to find and cheap relative to gen1 parts. I ask, because I have acquired myself an 1992 Gsxr 1100 engine recently, so there might be a 1216cc turbo build on the horizon... One idea is also to use gen2 pistons if they are good for boost, but use ie. maxpeeding gen2 busa rods with upgraded bolts.

-

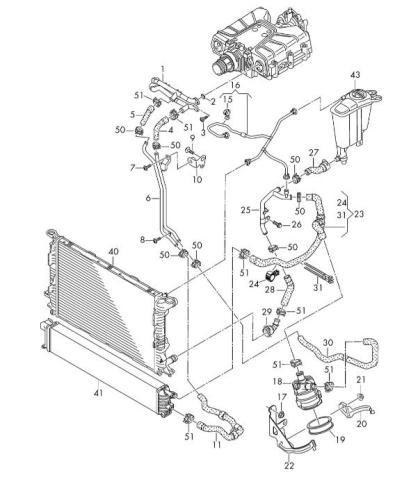

Atleast Audi uses on the 3.0 TFSI engine, the supercharged variant, engine coolant to cool the charge air. There is two cores intagrated to the Eaton itself (TVS R1320) and an extra radiator at the front. It is basically it's "own system" as there is only one small waterhose from expansion tank connecting the engine coolant circuit and the supercharger cooling circuit. Engine side has it's own mechanical waterpump and supercharger side it's own electric waterpump. I think Audi did this so they can get away with only one expansion tank and water adding point. Added parts diagram pic of a S4 with the same engine. I have myself a 2009 A6 with this engine and can confirm that it uses the same coolant, as I only added water from the expansion tank to whole cooling system while I did the infamous PCV servicing along servicing the Eaton itself. The system itself has 4 bleeding points with brittle plastic bolts and a specific procedure to bleed it correctly. From what I have read online, the charge air side of the cooling circuit stays actually a bit cooler than the actual engine coolant side, thanks to the only one small pipe connecting the two sides, but people still divorce the system in the hopes of better cooling. I actually noticed on our company van (2022 VW Transporter with 2.0 TDI) also uses air to water charge cooling, when I checked it's engine this week. Pic included. Also good info from Arttu about the core what you linked and water pumps. That universal core might actually be able to be fitted as a part of a plenum under SV tank, if the other sides pipe fitting is removed and the rest welded on the plenum itself. Thanks. It's good to hear other peoples thoughts and ideas on this planning stage, so I don't get too fixated on my own plan.

-

Great response from Arttu once more, thanks a ton. On my build, which is for the street, the idea is to use as large vertical radiator next to the engine as feasible and good looking to install. Or possibly two, one on either side of the front cylinder, if there is room left on the turbo side. One idea is also to use bigger coolers mounted like on Gurls blouse VFR 1000, but that just looks goofy to my eye, so don't really plan going that way. Also planning to install expansion tank somewhere to up the water volume. Time will tell, when I begin the build, as now it's on the desing stage in my head and plans might change a few times before actual build begins. Have to also google which electric pump would flow well with a small current demand. My power goal is fairly reasonable at ~200hp (from 120->200 on the bike). The turbo I am considering doesn't flow much more than that. I am not after peak power but rather an early spool for the street. My Frankenstein oil boiler with the same turbo (GT2052) is really good to ride on the street now as it spools already around 3k rpm so basically it feels like there is no turbo lag and no sudden burst of power. Feels like an NA bike but there just is lots more power to use if wanted. Might lose power at the top end if doesn't flow enough, but dyno will tell it in someday in the distant future if I need to use a different turbo on either of the bikes. With SV there will be rather long runners (also unequal lengths) before the turbo so that might effect negatively on the spool. For this reason I was considering supercharging first, but there just isn't room for an Eaton on the bike and Rotrex isn' positive displacement, costs like a liver, one arm and a leg to purchase so turbo it is. I didn't even consider the cooling capacity of the 1.0 tsi cooling block, that is a good thought Arttu. Will try to google stuff and if I don't find a better suitable heat exchanger I will still try this one. One thing came to mind that those are run with engine coolant, atleast my Audi 3.0 supercharged runs engine coolant through it's blocks, so people divorce those systems in hunt for better cooling, so the 1.0 tsi block might perform better if coolant temp is considerable lower than engine coolant temp. If I can't find a better suited charge cooling system for my build (no matter what style) with my googling and planning skills, might just give my plan with the 1.0 tsi cooling block a try and see how it performs. There is a great change it might be done wrong and not perform as expected, but it won't be known if not tested.

-

I know this is an old thread, but has you or anybody else managed to try if air to water works or not on bikes? More and more modern cars seem to be running air-water cooling. For example 1.0 tsi vw golf/skoda octavia (3 cylinder versions) run a quite good looking boltable cooler package on the intake, which seems to be "easy" bolting to a custom manifold. The heat exchanger is similary sized to a brick so would be doable install to plenum. I am considering air to water intercooling with seperate heat excanger from bikes water cooling circuit setup for my upcoming build as there is no room for an actual intercooler on my bike. Might be able to fit a thin extra radiator at the front or a motocross style vertical radiator next to the front cylinder but no way an thick actual air-air intercooler without completely removing the oem radiator and building a custom cooling setup from scratch (which I rather not do). Future turbo build bike is not an oil boiler but SV 1000 S so a V2 engine with room on both sides of the front cylinder. Other side of the front cylinder will be taken by the turbo though. Air-water cooling sounds tempting over water-methanol spraying, as there wouldn't be need to fill up time to time with "boost juice".

-

Heavy duty parts for short stroke 750?

IhmeJanneFIN replied to IhmeJanneFIN's topic in Forced Induction

I want to know also more of this -

Heavy duty parts for short stroke 750?

IhmeJanneFIN replied to IhmeJanneFIN's topic in Forced Induction

Still have the bike and not going to get rid of it. Too much money and too many hours invested to this piece of extreme "engineering". Katriders site is quite dead, i noticed that someone had messaged there something, but I haven't had time or memory to response there. This is still going to be my testbed for my "actual" turbo build which I plan on building in a year or two from my other bike. I try to hone my skills with this bike and test my crazy ideas and carry on with the working ideas and scrap the bad ideas when building my second turbo bike. -

Heavy duty parts for short stroke 750?

IhmeJanneFIN replied to IhmeJanneFIN's topic in Forced Induction

Long time no hear, or see, sorry about that. Winter came... Unfortunately no updates for now as being a family man for two, under 2 year old daughters and need to go to work etc, so garage time is limited to about 1-2h / in the evening/early night if I happen to have any energy left after work. Also different projects ongoing also, so this bike building is kinda pushed back for now. It's plan to start working on in when the spring gets closer. I fired it up few weeks back though. Fired right up (thanks to my prime relay circuit of ~2sec, which I cycled a few times so got the carbs full of gas). Idled great, good throttle response, no smoke. Bike had ran last time in September 2022, so a good 4 months it just sat in semi warm garage. Yea, snow came so I had to go my cave and roll the big boulder to work as a door and keep the snow and nosy neighbours out and heat in. Also no interned or electricity there, so back to being a caveman for winter. Just came to see if the spring is here as there was a flood in my cave from melting snow. It only turned out to be the global warming giving as oddly warm weather in the middle of the winter, so soon I will go back to my cave. Well, that's not entirely true, we are civiliced people here in Finland with warm houses and good living Just have to deal with the polar bears from time to time and punch them barehanded it the face to keep them out of my pantry, as they live in the forest next to me (this is also not true, we don't have polar bears here) Actually, bore is still original 73 mm, only stroke has been increased with the 1100 F crank. Spacer under barrels, differend rods, different pistons, different clutch, different this, different that, different those, different these, different bolts, different nuts, different plastics, homemade engine cover with oil drain hole etc. It's a hell of a parts bin Frankenstein waiting to blow up Don't remember if I told about the engine in detail on my previous post. But yea, idea of this bike is to hide the turbo under the fairings, so outside, to untrained eye it looks like a stock F, with different exhaust cans, when it actually packs somewhat a punch. No match to busa or 1000 cc super bikes, but better that a stock F. I did though rode the bike few hundred km's last summer. Just had issues with my homemade alu blocks for oil cooler fittings as they were weeping oil, so no long test rides. And had to take care of my kid as I was on a paternity leave from work and wifey went to work, so only had little time to work or ride the bike. Here is a link to a short crap video I made with my phone a while back. Quality is terrible, content is terrible, camera man is terrible, sound guy is terrible with music and the camera I have is a cheap chinese, but there is some engine sounds in few spots which are audible and maybe the front wheel came off the ground when accelerating https://www.youtube.com/watch?v=VRfkiHI9-G4 And our clear drinking water may actually be pure vodka, we don't know, we just drink it straight from the tap, so we are used to it, so it may explain some of my crazy talks and my crazy mind in building bikes -

Heavy duty parts for short stroke 750?

IhmeJanneFIN replied to IhmeJanneFIN's topic in Forced Induction

I retarted it about 4-5 degrees. I must have misunderstood the meaning of minus and plus on ignition timing back in the time when i wrote here. Updates on the engine is, that it is currently a running testbench with a truly Frankenstain engine waiting to blow up. Basically it is a 988cc engine, which is achieved with: Stock 750f engine block (6 speed) and cylinder is stock 748 block with 12 mm spacer under cylinder. Cr about 8,5:1. Stock 1100F crank (helical gear, but cost only pennies vs 1127 or 1052 crank) Stock 1000 k2 gsxr pistons Zx14r rods, shorter and a bit beefier than 1100f rods, so thinner spacer needed. Rods were machined thinner at both ends to fit crank and k2 piston. Running with 1100f bearings as there was too much clearance with even thickest oe. zx 14 bearings. (had to make new stop grooves for the bearings). Small end bushed to 20mm->16mm. Oem 750f cams timed to about 110/110 degrees to suit turbo better. Custom build 750f clutch as the 1100f i bought had shot discs and didn't fit under 750f right side engine cover (basically 750f clutch basket with swapped 1100f helical gear). 6 spring pressure plate with 2 heavy duty and 4 oem springs, so clutch lever is still ok to use. Hydro clutch conversion. Seems to work fine for now and holds current power levels. Hoping to achieve 200 hp at the crank, anything over that is a plus. Still running GT20 turbo from the M-B but with new custom made manifold. Turbosmart "style" external 40mm wastegate with screamer. Two stock 600f oil coolers, upper one for engine, lowe one for the head. Oil temps have maxed at 86°C when cruising even with outside temp at near 30°C. There simply was no room to fit aftermarket oil coolers as they are way thicker than oem suzuki ones. Plus these 600F coolers cost like few pennies vs. aftermarket oil coolers. Plenum has two reed valves to help engine breath more freely when not on boost, as it doesn't need to suck air through the turbo and boost piping. Stock 1100f cdi box with ~4° retard by turning base plate. (1100f cdi has lower redline than short stroke 750f). Gsxr k6 600 COP coils. Hoping to run efi someday Turbo starts to boost around 3000 rpm and hits max boost around 4000-5000 rpm, so basically there is no boost lag if rpms are above that. Bike drives like an NA carburated big cc bike (like a stock B12 bandit what I drove years ago). Power comes on linear and there is no huge spike in power like there was with 750cc turbo engine. With bigger cc engine it has enough torque to cruise low speeds near idle and still accepts throttle inputs. Gearing is 17-43, so rpm is about 4000 rpm at 110 km/h at 6. gear. There is no boost and no exhaust pressure when cruising, but if I floor it, it immediately starts to boost and basically has full desired boost in a few seconds. Boost pressure can be set at different levels with a flick of a switch by my right thumb. I have done a relay mod to my lights, so my original light switch on the right hand is now used to control solenoid valves which control boost. Basically one basic solenoid valve and 2 stage boost controller in line. Basically with my "lightswitch" at "no lights" setting, it is running on spring pressure of 0,6 bar. With only "park on" it can run anything between 0,6-1,2 bar. It's currently set to 0,8 bar. And with "driving lights on" it can also run anything between 0,6-1,2 bar. It's currently also set at 0,8 bar, as I want to test drive the engine a bit more and add water methanol charge cooling before upping the boost. I have a boost gauge, exhaust back pressure gauge and wideband installed. When boosting 0,6 or 0,8 bar, the back pressure is little over 1 bar. A bit on the highside, but still quite ok and engine seems still happy and lively. Even with 17-43 gearing, it lifts the front with ½ throttle at 1. gear when full boost hits. With the boost set at 0,8 bar, it's quite a funny feeling to accellrate as it wants to wheelie on 2. gear with about ¾ throttle and around 100km/h on the clock, so there is definately power on the engine, the reliability is the only question now, which i have to continue to test and dial the lower rpm afr's. Currently fueling and drivebility is ok at wot and cruise above 3000 rpm, but at revs between 2000-3000 rpm, it likes to surge for some reason. I thought it to be lean surge, so I richened the mixture there with different idle jets, but that doesn't seem to be the case, because even with 12:1 afr it surges identically as with ~14:1 or ~16:1 afr. Might be the new placement of my reed valves that disturb the flow inside the plenum, so I need to try different locations and recheck my carb sync at that rpm. But here is a pic. Turbo placement is quite unusual, but it still fits under my new fairings (in the middle of facelifting my pre F to post F, so more room came available for turbo placement and now able to drain turbo with gravity). Heat from turbo and downpipe might become an issue and might melt the plastics, but I try to deal that with heat shields, turbo blanket and exhaust wrap when the time comes to fit the fairings. Frame is currently stock, but with post F swingarm fitted with gen 1 busa rear wheel and 190 tyre. Front end is from -03 SV1000 S which I had laying around from my other bike after gsxr front end swap. Front wheel is from srad gsxr. Still need to get it painted black at some point. -

Heavy duty parts for short stroke 750?

IhmeJanneFIN replied to IhmeJanneFIN's topic in Forced Induction

Glad to hear that someone else is also mad enough to build these smaller engines. At the moment my engine is in parts as I try to build a "stroker" engine with different crank and rods, but use the original lower end and block & bore with k2 gsxr 1000 forged pistons. So I need quite a big spacer to lift the block. And I am trying to limit the spacer height, so I ended up trying shorter conrods. Everything on this engine build is still unsure and very experimental, so I have no idea if it would even work. Will try to post results if I get it done. -

Hi all. Been thinking pistons for my boosted short stroke 750 project and came across that gsxr 1000 pistons are 73mm which seem to be forced by looking at pics. The diameter would fit on my current bore on my engine. Problem is that these pistons use a 16mm wristpin and my engine uses 19mm wrist pin. Height wise I would have to calculate compression and hope for the best if I am to fit these. I have seen people fit bronze bushings on the small ends to fit the smaller wrist pins on some automotive applications and also some oem conrod seem to use some sort of bushing at the small end from the factory. If I would be to fit such bushings to my conrods, any idea what material it should be? Obviously it is a machineshop job as the inner diameter has to be honed to correct dimensions.

-

Heavy duty parts for short stroke 750?

IhmeJanneFIN replied to IhmeJanneFIN's topic in Forced Induction

Been thinking the pistons for my project as I found signs of starting failures on my oe cast pistons. I noticed that k1 k2 gsxr 1000 has 73mm and from looking at pictures they seem to be forged pistons, but 16mm wrist pins. So my thought was next: can i bush the oem conrods 19mm small ends to 16mm using properly sized bushes (obviosly at engine shop)? I have no idea if the pistons height and any other dimensions would work for the short block engine to make decent compression for turbo and not hit the valves. Anybody has any info on this? -

Heavy duty parts for short stroke 750?

IhmeJanneFIN replied to IhmeJanneFIN's topic in Forced Induction

It has been one of my stupid goals with this to keep the oem looks, so bike looks as ugly as it is with them, expect the back end is swapped from a 600 purely for "better" looks. Then I would consider the looks a success. Thanks. -

Heavy duty parts for short stroke 750?

IhmeJanneFIN replied to IhmeJanneFIN's topic in Forced Induction

Uuuuhmn, I haven't said that word on this site, have I? I myself know it only as GSX 750 F, as that is what reads on the fairings and I have spoken about this bike as an F, right? And I put that "name which should never be pronounced here in this site" in parentheses to the youtube video name only as clickbait for my the fellow bikerfriends on the other side of the big pond also known as Atlantic ocean okay, maybe i should't have posted the video and fleabay link in the first place as for the sacred rules, so why I decided to remove the links so you wouldn't loose your good night sleep because of me -

Heavy duty parts for short stroke 750?

IhmeJanneFIN replied to IhmeJanneFIN's topic in Forced Induction

Thanks. Fun is the exact thing I plan to do with this project. Good thinking about the pistons. I would have wanted to run an intercooler as it would so much easiers than to fill up with "boost juice" time to time, but the space at front of F is very limited. And I don't have equipment or skills to do alu welding for an intercooler. Even my turbo is at about an 45 degree from transverse to allow clearance for front wheel and my air cleaner is poking a little bit past my righthand front fairing. Looking at pictures of B12 turbos I would say i have about half the space between engine and front wheel, as my exhaust runners are basically nonexistance as I run a log style manifold. Basically what this bike is, it's a learning platform. It's my first ever turbo build so my plan is to do things "cheap" and somewhat differently at some things and check what works and what doesn't. Take notes and try to replicate the good ideas and toss away the bad ideas for the next boostproject in a few years. Btw, about my setup. The turbo I am using is a GT20 from a 2.2 liter CDI diesel merc (3 bolt pattern). At the merc it is cabable to do a little above 200hp, so my hope is it would do the same on my build. As this GT20 is from a diesel engine, it has a bit smaller exhaust housing as it's petrol variant, it likes to start building boost at quite low rpm. Also because of that I haven't found a specsheet for this turbo. This turbo is a non-VNT variant. Would like to try out a VNT for the kicks of it at some point. The turbo cost me 50€ so what the hell, I just slapped it in there as a try to find out if would even boost before redline. I was quite pleased to find out it boosted quite early actually and still revs to redline quite easily. Because I didn't have any intercooling last summer, the torque started to die at higher rpm quite quickly, so my high intake temps might have been the cause. On my katriders site the dyno sheet can be seen and other bits of my mods. https://katriders.com/forum/service-department/exhaust-mod-shop/2120086-yet-another-turbo-build-but-bike-is-actually-running-already I am also still running stock ignition with +4 degree timing by turning the base plate of my ignition (yeah i know, crazy) but it still works even at redline with JR9B plug gapped smaller. With original gap it started to misfire near redline. Some point I wish to update to atleast dyna coils or even to full programmable ignition (Speeduino maybe, Dyna 2000 is quite expensive for my taste). Fueling is still done by original 36mm carbs with a bit smaller main and pilot jets actually. Malpassi 1:1 fuel regulator with about 2-3 psi base fuel pressure. I also have factory pro needles at the moment on, cause it works best with those on off-boost situations. If I floor it before boost it goes too rich at around AFR 9, but once it starts boosting the AFR goes to around 11,5-12 and stays near that to redline. With oem needles it was jerky on off-boost situations and I rarely floor it so the AFR stays quite nicely around 12 at low throttle openings at off boost situations. Might try some stiffer springs at the carbs to slow down the slides with the factory pro needles as I think they rise too fast which then causes richness (or I am thinking this wrong)? Cams and timing are original, but plan is to make adjustable gears and try the 110/110 timing. Exhaust what I had last summer was a single Viper can on the right side. Now I have updated to 2 cans purely just for the looks. Exhaust was and still is 2,5" from turbo to can(s). Can outlets are around 55mm. Boost was originally controlled with the internal wastegate but that proved to be insufficient so moved to turbosmart style external wastegate with screamerpipe. Maybe I should make a new thread of my build, and try to keep this topic focused to the actual engine (addes some pics of my bike) -

Heavy duty parts for short stroke 750?

IhmeJanneFIN replied to IhmeJanneFIN's topic in Forced Induction

Well, when I get my hands to that piston and do my measurements I can provide some info then. But before that I fear I have not much to provide atm -

Heavy duty parts for short stroke 750?

IhmeJanneFIN replied to IhmeJanneFIN's topic in Forced Induction

Thanks, but as stated, this is the engine I have and plan to use for this project for reasons of my own (stupid? maybe? crazy? definately.) so any info for this is still needed if any is to be found at all... I can live with that info also that nothing is to be found. At the moment I only would want to break the 200hp barrier at the crank (my engine dynoed 174hp at the crank last summer), so no need to go further with this build. Maybe my next project after a few other projects in few years will be a B12 turbo or some GSXR with a charger with better aftermarket support. I know the engine is not the best canditate for more power as stated in my first post. But there are still a lot of people around the world running these short stroke 750 engines (mostly NA i would presume) for some crazy reasons of their own, so can we please, try to gather info of this specific short stroke engine here or show a thread where this info is, rather that tell of the bats "get a bigger engine"? As far as I know there are this engine specific forced 73mm pistons to be found, but they seem to be higher CR versions only. So far haven't found any beefier rods that use the same size bearings as stock crank. 1052 crank would fit the cases, but would require much more extra bits and work also. Cams from few different engines fit. More of those in Frankenstain guide. -

Hi all. I am asking for some info for some beefier parts for my bike as I am in the middle of building my GSX 750 F -94 engine to better suitable for bigger boost (about 1.0 bar). My main questions is, are there any HD aftermarket or oem parts like HD studs, conrods or pistons (more of these later on, I want to know your opinion on my idea) that fit the short stroke engine with no or little mods. I don't want to throw thousands and thousands of euros to engine workshops for minor effects on this project. I know the 1127 or B12 conrods don't fit because of the difference with big and small end holes (btw. short block 750 wristpin is 19mm, not 20mm) and because of the stroke is different also. I know the engine is not the best platform to start with as 1127 and B12 are bigger cc engines and better suited for boosting as the aftermarket parts are easily available, but this is what I have and this is how I plan to roll to with my faired sleeperbuild. I have already rode the bike for about 5000 km as boosted with mild pressure (max of 0,65bar and 174hp at the crank) as I don't have an intercooler (I am in the middle of installing my diy water methanol kit though). Now I have disassembled the top end of my engine as I am planning to install a diy spacer under the cylinder block and in the process I noticed small cracks on two of my pistons. On #1 I have a crack between my top and bottom ring on the intake side. This crack goes all the way to the bottom of the ring crooves and contiues hidden there as part of the piston between rings can move a little up and down and I can feel a small high spot on the crack with my nail. On #3 I have a small crack on the top of the top ring and intake valve crevis, which at the moment is only at the surface as the crack cannot be seen at the ring groove. On top of the pistons I can't see any marks of detonation, so this might just be failure of the material? So my initial plan was to just get two replacement oem pistons, but o boy they are a bugger to find "cheaply" and have always wondered if there would be any better and stronger ones out there. As I digged around the Eblag and partzilla part numbers I came across DR250/Burgman 250 pistons. They are 73mm bore and 19mm wrist pins and the different heights of this piston is identical to the 750 short stroke oem piston. Only difference that I can see from the pics is that the DR uses flat top pistons and the 750 have crown on them, so the CR would be significally lower and squish would go to hell. The amount how much lower the CR would be ks unknown at the moment. But have ordered one of these DR pistons edit: fleabay link removed to measure if it would be suitable to be run in my engine. Ad states that these are forced pistons (chinese pistons so you can never say for sure) so they should be stronger, right? As far as I have googled the valves are about the same size in both engines but the angle is also unknown, so there might be issues with piston to valve clearance. I know that the CR would drop significally with these pistons but my question is how low I could drop the CR to still have a rideable streetbike? Also the squish would suffer greatly. As stock this 750 engine have 10.9:1 CR (after 7k rpm though because of valve timing) and on the bigger oilboilers people seem to run as low as 8.5:1 CR when build for boost. These engines are a lot bigger cc though, so the off-boost torque don't suffer that much than it would on a 750 engine. As the engine was unopened on my bike last summer, the bike would start to boost around 4k rpm and at around 6k it would already have near the max boost and a wonderfull screamer soundtrack. (Fyi, turbo is from a 2.0 cdi diesel mercedes, non-vnt). So if I can keep the low rpm turbo spool on my engine that shouldn't effect the rideability too much in my opinion, but that might be wishfull thinking. Ps. Sorry for long post, so here is a link to my bike on youtube making tsu tsu sounds edit: youtube video link removed

-

Hi all. Long time reader, first time poster. I have been reading this Frankenstain guide and almost every other build thread to these oil boilers like a bible as I am "building" my own short stroke F engine and I noticed a little error on the guide. Just asking that have anybody else noticed the same thing. The guide I am speaking of: https://oldskoolsuzuki.info/archives/tag/1127 In the guide reads that short stroke 750 ie. 88-89 gsxR and 88-97 gsxF (I highlighted R and F to make a clear separation) along with 1127 and B12 use 20 mm wristpin. In my opinion the short stroke 750 use actually a 19mm wristpin. I myself have a 1994 gsx 750 f as a turbo project and two of my oem pistons have developed little cracks between rings so started to look at alternatives and noticed this when measuring my pistons. I don't have short stroke 87-88 750 R engine on my hands so cannot say anything to certain of that, but atleast partnumbers for both engines pistons, cranks, conrods etc. are the same, so they should have the same size wrist pins also. What do you think, do you agree with me on this or am I just unable to use a vernier? I know there is mixed info on the net about this, as one some posts it is said that its 19mm and on some it is 20mm. Ps. I messaged Katanamangler also of this and he recommended that I start a new thread and if people agree with this he can update the info on the guide.