imago

Traders-

Posts

3,024 -

Joined

-

Last visited

Reputation

3,729 ExcellentPersonal Information

-

Location

Birmingham, UK

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

Be good to see you, and needless to say there will be ET content.

-

Just updating this with confirmation it'll be late June (weekend 21st or 28th). Also to say I'm currently working on a magazine/blogger/vlogger attendance that will hopefully tie up with Kickback in Malvern. If it comes off then the idea is a background thing on the bikes and people out in the wild. I'll update as things go along, but if you want your bike to be photographed that'll be fine, equally if you don't (on the run, shy, misanthrope, whatever) then that's fine too. Other than that it'll be the same as last time.

-

GSx1100 Dresda Solitaire (I may have had a Clivecident).

imago replied to imago's topic in Trick Frames

Two stroke stuff with any level of performance now is (as I'm sure you're aware) ridiculously expensive gear to play with. If it had one in when I got it then I'd stick with it, but as it didn't have anything and its last engine was air cooled options were/are wide open. -

GSx1100 Dresda Solitaire (I may have had a Clivecident).

imago replied to imago's topic in Trick Frames

I presume that either the DVLA re-issued it, or more likely someone used the logbook when the Dresda went abroad. The V5 it's on now has the correct Dresda VIN, and the make is "Suzuki Dresda" so it's all in line with the bike and as it's properly registered on a 'Q' the insurance side is easier too. It didn't have an engine in it when I bought it as the GS motor had been taken out to use in something else. I was going to fit a GSX1100, but the most likely now will be a GSXR750 engine. There definitely won't be a Kettle engine going back in it though unless someone else buys it and does that. -

GSx1100 Dresda Solitaire (I may have had a Clivecident).

imago replied to imago's topic in Trick Frames

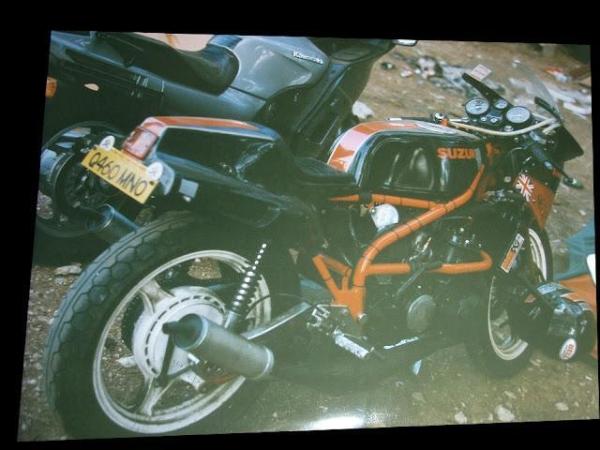

I'm told that it went to Europe and when it returned in 1990 DVLA wouldn't return the original reg so it went on a 'Q' plate. This is it in the early '90s, I got the pic from the bloke who owned it at that time when he saw my post on facebook. -

GSx1100 Dresda Solitaire (I may have had a Clivecident).

imago replied to imago's topic in Trick Frames

Yes it is, had a kettle engine to start with, then a GS1000, time in Europe, re-imported, put on a 'Q' plate. Sat in a shed for years, sold on from a deceased estate, then bought by me. Is it the bike in your 2 Stroke pics? -

I think I'm right in saying that you can get bearings with the groove but not the pin. If you can then Mike can bore for the pin and I'm pretty sure I've got some of the 2mm pins.

-

There's a lot of regional variation at play, but in the UK I can reverse those prices for decent quality pattern sets. Another big difference is that for the air cooled engine you have to add on OE crank and gearbox seals as they don't come with the kits, but they are included in the B12 kits. Second hand price wise you can buy two decent/running B12 engines for the price of an unknown GSX. It's not a cheap exercise to rebuild any engine now though. As @Dezzasaid, it's all the little bits and bobs which add up, especially when you have to buy things like valve stem seals twice as none of the ones included in aftermarket kits seem good quality.

-

With the usual caveat "as long as they're done properly" then no, cams from Kent for example are as good as OE. Aftermarket cams tend to be better quality than the originals and the manufacturers aren't interested in exchange which is why they're more expensive. They also offer a wider range of profiles as they start with blank cams and grind them to suit rather than the more restrictive option of reprofiling an existing cam.

-

I don't know if there's been a recent change in management or something, but CMS have been really good over the last few months. Really rapid delivery, costs generally lower than Robinsons, no stock issues.

-

Age has a lot to do with it no doubt, as you come forward in time the rebuild costs get cheaper. All the gaskets etc to rebuild a B12 for example will cost you 30% less than an air cooled engine, and the engines themselves SH can be had for 1/3 of the cost of an air cooled. It's just market forces, but knowing that doesn't soften the blow any.

-

It's very difficult, in fact virtually impossible, to get trade prices on air cooled stuff now. There aren't many manufacturers and suppliers which means they sort have a monopoly, then add on that no one (including me) is buying it very often and there isn't really any wriggle room for them to give discount. Some from CMSNL and some from SPS/Grumpy, you just have to check their sites to see how it works out price wise. I don't really use Robinsons much now as I find CMS have more NOS stuff and even with them being inside the EU it works out a bit cheaper. Inlet rubbers for example are currently cheaper at CMS than any of the others, but next month it might be cheaper to get them from SPS. My intention at the moment is to build the three engines I need for bikes, one to keep two to sell. The rest of the engine parts will then get run through the vapour blaster and sold on as there's quite a lot of stuff sitting there which isn't doing me or anyone else any good.

-

You don't notice it as much when you're buying stuff here and there. When you have to get it all in one hit the old bloke's cry of "How fuckin' much?!" goes up. Cams are a fierce bloody price now too I notice, there's only the reprofiled Kent cams that are anything like sensible money even if they are exchange and 493 rods are £250 each.

-

I have two ET/EX/Kat engines to build and I've just done the gasket and seal shopping. Just the consumables, no fancy bits or components as fortunately I already have those. I also have one new cam chain and tensioner so only had to order one each of those. A grand, one thousand pounds, for seals and gaskets. Add on cleaning, vapour blasting, painting/polishing, cams, big bore, crank building, studs, labour etc and air cooled engine builds are at the point where they're only viable for the dedicated fan with deep pockets.

-

To be fair that's more accurate than CDI as it's electronic it controls the spark.