smudge

-

Posts

55 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Posts posted by smudge

-

-

Sup lads, I have just finished painting my engine and tidying up a few bits and pieces on my never ending slabside streetfighter project , I still have to get paint on frame and bodywork and then get ready for assembly, the engine/ frame and suspension/ cushion lever bolts that came with the bike originally are a bunch of mix n match rusty crap I was planning on replacing them with a2-70 stainless bolts but I'm not sure how they would hold up? Are they strong enough for the engine mounts and suspension parts? I can make out a number 7 on the bolt heads which I think is equivalent to an 8.8 ? Would I better to use titanium on critical parts? As usual any advise is really appreciated.

-

1 hour ago, Maggotbreath said:

Nice mod! What gauge ya going to use.

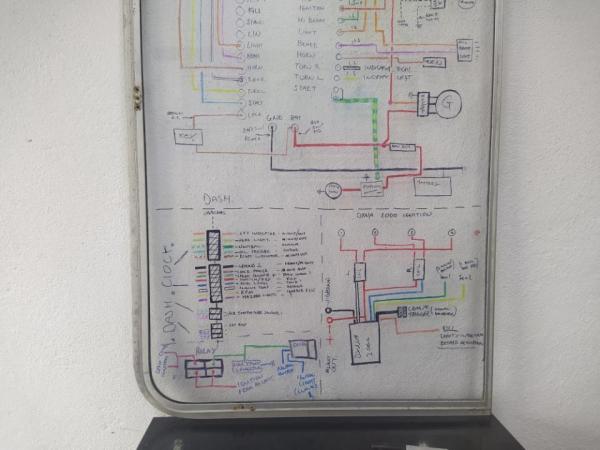

Cheers bud, I'm using an acewell clock , it has a built in petrol gauge. If you wanted to keep your original clocks you could always use the bandit 12 fuel gauge , you'd just have to wire it up write.

-

-

Sup schoolies , i moded my slabie tank to give me a few extra litters of fuel and fitted a fuel level sender from a bandit 12 , I'm planning on clocking up a few miles when this lockdown bullshit ends (if I ever finish this project that is!) I have no idea how accurate it's going to be , I'm planning on fine tuning it so it reads empty when I need to switch to reserve, to be honest if it gives me some idea of what's in the tank I'll be happy, hope this helps some one, I'll let yous know how it works out.

-

1

1

-

-

Thanks bud ,that's a great help, really appreciated .

-

Sup schoolies, smudge from Ireland here , finally finished making the seat/subframe for me Street fighter project , next job is to weld in a fuel level sender from bandit 12 into the tank and maybe increase the fuel capacity a bit by extending the tank in to the space the air box use to be, any one got any advice on best way to prep and clean the tank before welding? Or any picks of similar tank mod? Thanks lads, all advice greatly appreciated .

-

26 minutes ago, clivegto said:

I have no idea but anything will fit with a bit of thought.

Thanks bud, much appreciated, if my bike turns out half as nice yours I'll be delighted, cheer's .

-

17 minutes ago, clivegto said:

Yes, you only need a bit of string to centre it down the frame from the headstock to centre the wheel, then use 2 long straight edges either side of the wheels (no tyres) to check alignment.

So I take it you never had the issues I had with the wheel being off centre to the right? I'm using the late model water cooled straight spoke wheel with the slingy left hand spacer (13.5 mm)?

-

hi, thanks for the advice and encouragement it's all appreciated, fitting the wheel is no problem, wheel alignment is the issue I'm dealing with , now that i know the problem is the wheel and not the swingarm (thank christ )this makes it easier, I think I will probably take your original advice and have the wheel/carrier machined 5mm to bring it into centre, or pick up the slingy 17/5.5 , I'll know more when it comes to final assembly and I can double check chain alignment and chain/ tyre clearance, just out of curiosity did you check wheel alignment after you fitted the "w" wheel? Thanks again , much appreciated.

-

thanks for the info, its appreciated , I have read so much stuff on the web about the 17/5.5 wheel upgrade for the slabby being a "bolt on job" most saying to use the 17/5.5 carrier and to space out the front sprocket an extra 2mm to get the chain alignment right, haven't found any that mention wheel alignment? Would really appreciate any feedback from anyone who has done this mod with either the slingy or the water-cooled wheel , was the wheel off centre? If so by how much? Do you notice it when riding? I'm going to look out for a 17/5.5 slingy wheel to check it out. Thanks again.

-

hi, thanks for the advice , like I said this is my first "proper bike build" mainly messing around with dirt bikes the last while, so any advice is welcome and appreciated, I measured like you said and I make it somewhere between 105 and 108 depending on which carrier you use , which makes sense because there's a 2mm difference between them? I don't have the original slabby wheel to compare (Jesus I wish I did ) engines not in at the moment so can't check chain alignment , remeasured the slingy 4.5 in the swinger and it's not as off as the water-cooled 5.5 one (2.5-3mm of center to the right) if the chain alignment was right I could live with that? Was wondering if the water cooled wheel is the problem , maybe this mod only works out with the 17/5.5 slingshot wheels? I thought the backend of the bike would be the easy part!

-

okay ,so after some advice I went and put the original swingarm back in with the 17/5.5 water-cooled and the 17/4.5 slingshot wheel and they to are 5mm off centre to the right ,(apologies to Metmachex) I have seen so many posts and photos of slabsides with the 17/5.5 conversion and although they do fit , are we sacrificing wheel alignment for chain/sprocket alignment? Would be interested in hearing from some one who has done this mod , thanks for all the advice and apologies for any confusion.

-

1

1

-

-

yea , your totally right on that, this is my concern with moving the wheel so far over , anyone got any advice on what they consider acceptable chain/ tyre or sprocket nut/ swingarm clearances?

-

On 8/16/2020 at 10:33 AM, clivegto said:

I have a Metmachex arm in my Turbo Slabby with 17x5.5 carbon fibre wheel. You need to centre the wheel first & by the looks of your setup machine the sprocket carrier down shortern the sprocket bolts make wheel spacors the all willbe good. Had a slingshot wheel in before the carbon one & that had a different setup to the one that's in now. Will take a picture in a bit.

Hi thanks for the advice, Jesus your bike is pure class! Yea i think I get what your saying , i need to basically move the whole carrier 5mm into the wheel so i can move the wheel 5mm into center then fanny around with sprocket spacing to get chain alignment sorted? When you had the slingshot wheel in did you have any trouble with it centering in the Metmachex swinger? I'm using 98 wheel with the slabb/sling left hand spacer.

-

4 hours ago, GeorgeEI7KO said:

A right ball ache with the arm. Regards from Athlone

cheers bud , regards from Tipperary.

-

-

yea, it took a feckin age to type out on my crappie windows phone, I'm knackerd now. ☺

-

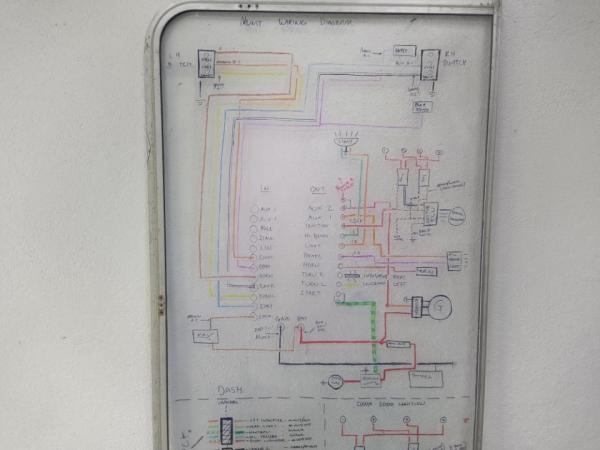

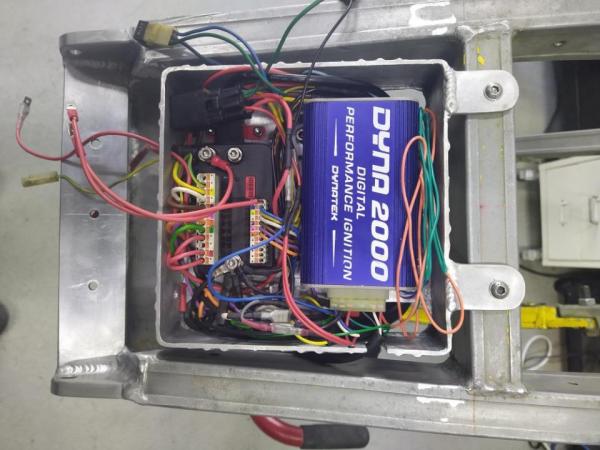

Hi, I'm Smudge from Ireland, I'm currently working on a slabby 1100 , I bought the bike about 5 years ago, it was in a sorry state some one had done a really bad streetfighter conversion, but it had the original 1052 motor which ran really well, my dream bike has always been a really well done 90s style streetfighter I just love them, so I started tipping away at it and collecting bits and pieces , so far I have put a complete front end from a 98gsxr 1100 on it with some lovely billet yokes , rewired it from scratch using motogadget m unit and switches and new ignition unit and a few other jobs that needed doing , the bike came with 17/4.5 back wheel conversion which I swapped for a matching 98gsxr 17/5.5 , the original swingarm was very tatty, and I always wanted a proper braced jmc style swingarm but couldn't get hold of one , about 3 and a bit years ago I managed to save up enough money to order one off Metmachex, after waiting about 3 months the swingarm arrived , I was gutted to find out that it didn't fit properly, there wasn't enough room for the shock to work properly ,after some emails, photos and phone calls they agreed to fix it, so I sent it back and waited again when it came back it still didn't work , so more emails, phone calls later they agreed to make a new one from scratch if I sent it back to them ,so I waited for another 3 months , when I finally got it back again it fitted lovely with plenty of room for the shock to work, I was delighted and thought nothing more about it, I am planning on making my own sub frame which will bolt on to brackets welded on to the frame, so before I started I thought I should check the frame over to make sure everything is straight and true , I noticed when checking wheel alignment that the back wheel was hanging out about 10mm over to the right! The frame is pretty good so I took the swingarm out, ran a straight edge down the sides of the wheel and marked off on the pivot tube and sure enough the wheel is 5mm off centre, this is my first project like this and would really appreciate some advice on how I could sort this out , I was thinking I could take 3mm off the left hand wheel spacer to bring the wheel more to the left while using the older sprocket carrier to give some clearance for the sprocket nuts and maybe packing the right hand side of the swingarm at the pivot point to get an extra mm ,I'm not sure how this will work out with chain alignment and chain /tyre clearance , I would really appreciate any advice or ideas, it would be a real shame not to use the swingarm everything else on it is perfect and I don't fancy my chances of getting my money back off Metmachex engineering! Big thanks to all the guys that contribute to this website, I've learned so much through it. Amendment- following advice received I have since rechecked the wheel in the original swingarm and the problem is the wheel I'm using NOT the swingarm . As far as I'm aware Metmachex engineering no longer make swingarms and Metmachex swingarms is now a separate company. Even though I had to send the swing arm back twice and wait fecking ages for it to be sorted, the quality of the welding and product in the end was still pretty dam good.-

1

1

-

Stainless bolt replacement advice???

in Oil Cooled

Posted

Thanks for the reply, from what I've looked up grade 5 titanium has tensile strength of 150,000 psi, which I think is a bout the same as 10.9 bolt, a2-70 and a4-70 SS have the same tensile strength (100,000psi) , A4 has better corrosion resistance? This is all info I have got from various websites so I could be totally wrong! I was thinking of using stainless for engine and titanium for cushion lever if I can afford it. Thanks again , all advice appreciated.