-

Posts

195 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Posts posted by majortom4

-

-

also wired in a switch for my oil pump, and cut and attached all my induction piping.

getting close to finishing now. just waiting for oil return parts and my friend to come and help me fabricate the manifold.

as asked before but with no answer.

if i take my bike to a dyno to get set up will i still need to buy and install a wideband 02 metre?? or not?

-

-

Managed to change float height by 1.5mm with movement still available. And changed them with them still upside down. If I changed them by 2mm they would jam and not move. (Metal tab would be stuck on jet thingy)

yer fuel injection sounds easy but expensive!!

read uncle bobs turbo page about pitot tube sizing and placement. Says he can't find any pros and cons with different placing. Don't know which one to go for now....... Want to go with the horizontal to air flow for ease of size changing if wrong size but don't because of it being a bigger obstruction. Hmmmmmm

wondering as well if I send my bike to a dyno to get set up how many hours do you think it would take? And also if I get it set up at a dyno will it still be a good idea to get a wideband AFR sensor and gauge or will I not need one??

-

@slingy1157 so I finally got the screw out. Bent the little tabs so floats are 2mm higher. But now the floats don't have any movement. Is this correct???

-

Sooooo many different ways of doing the pitot!!! I really don't know which is best.

So putting the tube in line (parallel with the inlet tube) is better than across stream? And should be 6mm not 10 like iv read in other places?

deffinitly witch craft voodoo shit!! Haha

-

Well that screw took a royal beating and now iv fucked it...... Time to smash a flat head or torque bit into it and see what I can do.......

I'll have a look at that thanks slingy.

thinking of putting pitot after elbow into plenum so on a streight section.

-

And wow I think the hulk has tightened the screws on my float bowls.....

-

Yer I have adjusted the idle fuel pressure on the regulator to under 2psi.

Do you know anything about the pitot tube setup??

-

Also lockwire or zippy tie the floatbowls vent hoses and fuel pipes to stop it all blowing apart with boost. Easier doing it with carbs off as very fiddly

yer going to lock wire those. Got a lot of lockwiring and jubilee clipping and stuff to do...... Zip ties have become my best friend as well haha.

-

Ok brilliant. Thanks for the answer and the explanation :-) will get that done before re-fitting them.

-

Ok so about to tackle pitot tube size,

just wondering if this concept would theoretically work?? (Seems good to me)

so what I read was that instead of just drilling a hole in the pitot tube, was to drill and tap a hole the correct size to fit a main jet in. Then if the bike runs lean or rich you can change the jet size in the pitot tube rather than re-jetting the carbs. Now I was looking at putting the pitot tube in not parallel but across the air stream leaving two ends to put my carb pipes onto, then from this info drilling and tapping a hole to put a main jet into.

do you guys think this would be a good idea? Or do you think the pitot would have to be parallel to the airstream for this to work?? Or not work at all??

-

Just a thought. Before I put my carbs back on, is there anything that I need to do to them?? Plug any holes or change anything??? (Apart from jetting if needs be)?

-

Then have the fun part of trying to set her up right. Definitely going to need you guys help on that bit!! :)

-

Been having a right nightmare trying to mount the fuel pump and pressure regulator without it looking stupid. Finally just about found a place with a couple of cable ties and they are on. Also plumbed in my manual boost controller to the in-built waste gate and blow off valve. Isn't looking as sharp as I wanted with the pipes but can't do anything different.

drilled tank overflow and blocked off hole at top so now have a fuel return. Fitted air filter to turbo, wired in fuel pump to switch live.

not too much left now really. Just waiting for some piping to come for the tubes to the plenum. Then it's just welding downpipes (probably going to be a lot harder than I imagine) , fitting AFR gauge and getting oil return plumbed in when the parts get here.

-

Mines insured with bikesure,they know all the mods £216 fully comp this year

Thanks Paulm I'll give them a shout at renewal time.

-

just wondering, whats a good insurance company to go with for a turboed bike?? just wondering if there is a special one with cheap prices that people use???

-

Ok will do. Thanks for that will get that wired in tomorrow or Tuesday, hoping my pump is going to be adequate for the oil return as it has to feed it up...... I'll find out when it's all wired in I suppose....

-

The pipe you can leave to atmosphere or just put a little filter on it, or a filter to the casing. It's only case ventilation for any vapour

Thanks for that. Know anything about the wiring???

-

-

been busy over last few days, managed to get the turbo mounted and made up a bracket to help support it, fitted oil feed as well.

need some help tho with where to wire my oil and fuel pump into. i have found a switch live (see pictures) and just wondering is it possible to wire both my fuel and oil pump into this one connection? or will it be too much and overload stuff???

Also wondering what do i do with this pipe?? (see pictures) it was connected to the airbox...... do i need to reconnect it to the plenum or just leave it???

cheers guys

-

Finally got a turbo! Been modified my it to fit on bike today, turned compressor housing round and made a mounting plate for waste gate, chopped and sorted oil feed and drain, mounted pump for oil return and gave the turbo a good clean.

now need to chop the manifold and the dump pipe down so I have. Falange to weld onto.

decisions decisions of where to mount it tho. Think it's going to have to be mounted pretty low to factor in size and oil cooler lines. Need to make some brackets up for it as well.

will try and get some pics up tomorrow.

-

Sooooo projects been on hold for a while as my turbo has been lost in tho post...... Awesome!

looking at buying a td04hl-16t instead of the td04l-14t. Hopefully be able to pick it up tomorrow if all goes well then can start getting on with it!

-

Yes mate you can

Thanks for clearing that up Pete.

-

So as my carbs only have one inlet pipe for fuel, can I use the other 'to carbs' outlet from the pressure regulator to have a pipe leading to my fuel pressure gauge?

Turbo charging my B12

in Forced Induction

Posted

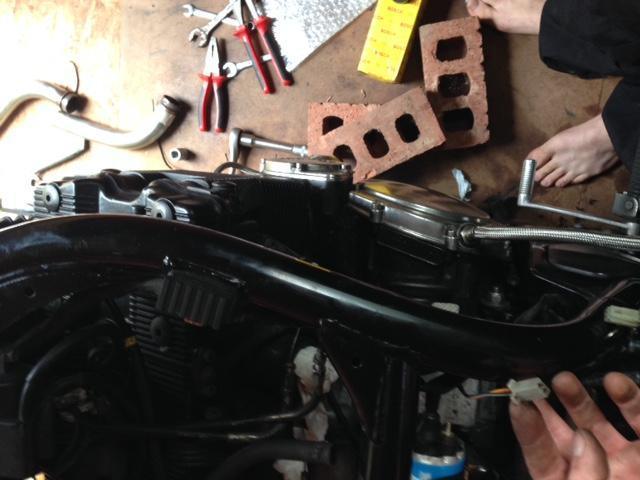

some more pics of where im up to.

had to alter the bracket for the turbo to lower it so it wouldn't be hitting on the wheel.... underestimated the size of turbo and how it would be when sat on and loaded.