kiwisuzuki1100nz

-

Posts

108 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Posts posted by kiwisuzuki1100nz

-

-

7 hours ago, IceKat said:

The most effektive weight reduction can be achieved by cutting out beer and pies

Very true. I shaved 10kgs so far and cost me nothing. I haven't cut out beer however as I still need a soul to ride

-

1 hour ago, clivegto said:

Get in touch with grumpy1260.

But I would say the 1127 ones will screw in far enough to fit the 1052.

Thanks heaps - yes they have them - just got to negotiate getting them sent downunder

-

Anyone know the APE HD kit that will fit a 1987?

CS1127GSX is listed as - Cylinder Studs - Suzuki GSXR1100 1127cc case (40mm Starter Hole) - Bandit 1200s

-

7 hours ago, Gixer1460 said:

I thought they were HD types from 1st photo - 2nd shows they are std waisted types - so stick with std torque figures! If they were HD then a single replacement would be ok but as i've only ever replaced std with HD I don't know about a std single replacement - should be ok though. I think i'd be checking the rest and then be prepared for others to let go!

Re. over torque - heavy nitrous and / or multiple bar boost requires more clamping pressure.

With an 1109 wiseco piston kit lifting compression to 12:1 will standard studs be ok or should I look at the APE studs?

-

All studs removed using a gear wrench stud extractor and the double nut technique.

Only two studs were super tight thank goodness.

Cheers for the help and direction appreciated

-

-

7 hours ago, Gixer1460 said:

First off 27 ftlbs is no way near enough to snap a HD stud - unfortunately I guess this one was defective or if second hand / used, then already stretched beyond its tensile limit - i've taken these to 60lbs although more usually 45lbs!

Whilst your noted method is unusual it could work but you have to protect from metal shavings from the stud being clamped to undo, escaping into the crankcase. I'd use plenty of cloth or paper towel to catch anything. Problem occurs if there is damage to the crankcase threads ie. cross threaded - then a full strip is inevitable!

Would you recommend replacing them all or is only changing a singe stud ok? I have nightmare visions of breaking studs at the crankcase.

In you experience are they bloody difficult to remove or relatively easy and what technique do yo use?

45lbs? I thought the max was 29ftlbs what had you done that required a 45lbs torque?

-

7 hours ago, clivegto said:

Have you just fitted the studs recently ? They look like HD ones.

No new studs - all old ones

-

Damnit just finished fitting my new 1109 pistons and was torquing down the cylinder head and a stud snapped. So many levels of pissed off right now.

I torqued it down following the tightening pattern in stages as per the manual and stamped number on the head. Max of 29 fl ilbs so set 27.

What have a screwed up? What can I do next time to not have this happen again?

The stud snapped just below the top thread after the radius curve to standard stud diameter. Any suggestions on how and the best easiest way I can remove the stud?

Can it be done without stripping the engine fully down again i.e. removing the engine block

Was thinking maybe I can lift the block up enough to get something on the stud to loosen it without removing the pistons from block.

FAAAAAaaaaark

-

Thanks everyone. Appreciate the comments.

I'm gonna go ahead and give it a go. Impressive 144bhp with stock cams

-

Has anyone done their own head work?

I mean casting clean up etc... and how successful was it? Any real dyno proof / photos?

-

roger

-

-

wtf?

-

-

What year are you after?

-

On 9/16/2019 at 7:03 PM, Torqueseeker said:

What sort of prices do they range from? I've contacted hagon for now but gonna shop about

https://www.nitron.co.uk/buy-online/motorcycles/suzuki/gsx-r-1100/k-n--89-92-

You'd have to give them a call and give measurements for your shock mounting spacing. They manufacture to order and I assume they can do a custom shock.

-

Just get the OEM ones. I used Partzilla

-

Nitron shocks are great

-

ok Thanks will stick with the stock .010 gasket.

I had read elsewhere a thicker gasket being used

-

Hi,

Sooo I have a 1109 wiseco piston kit on the way.

With the compression increased to 12:1 should I use a thicker base gasket i.e. instead of a .010 inch use a .020

Copper or steel? -

ok thats not so bad and thanks!

I assume sump pan swap means fit the 1052 sump pan on the 1127?

Are the exhaust port centres the same? i.e. my current 87 headers should just bolt in

Can you elaborate on the single ignition pickup? Is that the signal generator under the right side engine cover?

-

Damn - dont think so 88 was the last straight bolt in

-

Is this a straight bolt in?

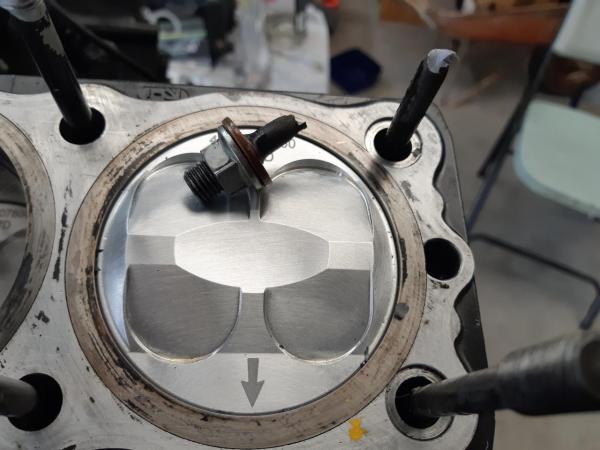

Stupid question - WTF is this

in Oil Cooled

Posted

Haven't been lazy. Went page by page through parts manual with exploded diagrams and can not find this.

Bike is GSXR 1100 H 1987

Am wondering if powdercoater gave me an extra to mess with me. Any clues?

Thanks