Buzuki

-

Posts

181 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Posts posted by Buzuki

-

-

-

2 hours ago, Swirl said:

Is that the wheel end, I'm after the pivot end, thanks thou

My mistake

, sorry , right answer is , Hollow type , 16mm diameter , and 282mm long measured without end bolt head .

, sorry , right answer is , Hollow type , 16mm diameter , and 282mm long measured without end bolt head .

-

Hollow type , 20mm diameter, and 345mm long measured without end bolt head .

-

As slab option , gsx750f 41mm legs and slabie yokes , lenght is similar as original around 785mm , https://oldskoolsuzuki.info/forums/topic/9500-gsxr750-resurecting-old-racer/page/4/#comments

-

More precisely ,

-for GSX750F model 1989 - 1997 = 491ml per each leg

-for GSX750F model 1998 - 2005 = 513ml per each leg

-

1

1

-

-

491ml

-

-

-

2 hours ago, Dezza said:

Is there a straightforward way to remove the starter (sprag) clutch from a slabside crankshaft without resorting to using a special puller?

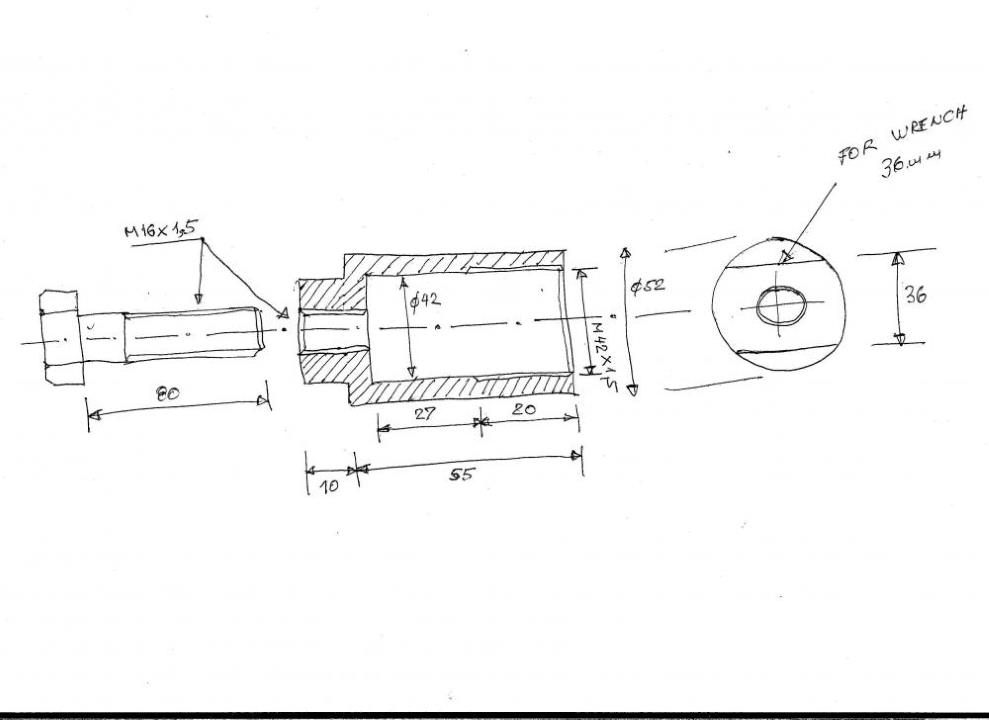

These days will make that puller for me on my friend lathe , material can be some better axle steel ,standard M16x1,5 bolt can be in strenght gradation 8,8 or stronger 10,9 .

-

1

1

-

-

36 minutes ago, Gixer1460 said:

Surely impossible as the pressure size isn't a closed system - the regulator only bleeds off excess pressure doesn't hold it / back it up completely plus there would be other instant damage to bearings / cams etc with no oil flow?

Well , regulator can bleed only limited amount of oil (excess pressure )but not unlimited amount , so if the engine was in very cold condition , let`s say in winter time and engine start was with instant high rpm that can cause excessive oil pressure even with oil pressure regulator that is OK , that can cause aluminium oil pump body to explode , in winter time I have seen similar effect on few automobile engine where oil pump not exploded but oil filter was .

-

On 4/16/2019 at 8:46 AM, MeanBean49 said:

Im pretty sure the oil pumps are the same in all the oil cooled motors. Everyone ive ever taken apart has been the same

Just opened two oil-pump , one is from slaby750 and another is from slingshot 750J/K , and they are internally different , slingshot750 is with bigger rotors diameter .

-

1

1

-

-

That blown oil-pump , maybe oil pressure regulator did not open from some reason and than generated excessive oil pressure caused pump to explode .

-

Well , it can be bad regulator ,or graphite brushes become to short , maybe graphite dust polluted rotor two cooper rings , also is good to check rectifier six diodes condition , but also it can be some bad contact anywhere in electrical installation ,

any way voltage regulator unit usually work good or is totally bad , is very rare that regulator is in some `overlap` condition between OK and bad .

-

1

1

-

-

-

In my R750J (88) for long time I use K&N dual pod filters (RU2922) , to get those BST36SS to work in proper way only I need was to change size of main fuel jets , standard #112,5 was replaced with #135 jets, original needle position was not changed , I pickup those new jets from some two stroke MZ/ETZ250 carbs

.

.

-

2 hours ago, MeanBean49 said:

Any set of cams can have a B on them, its just random, just to do with the batch number, had them on alsorts of cams from different models

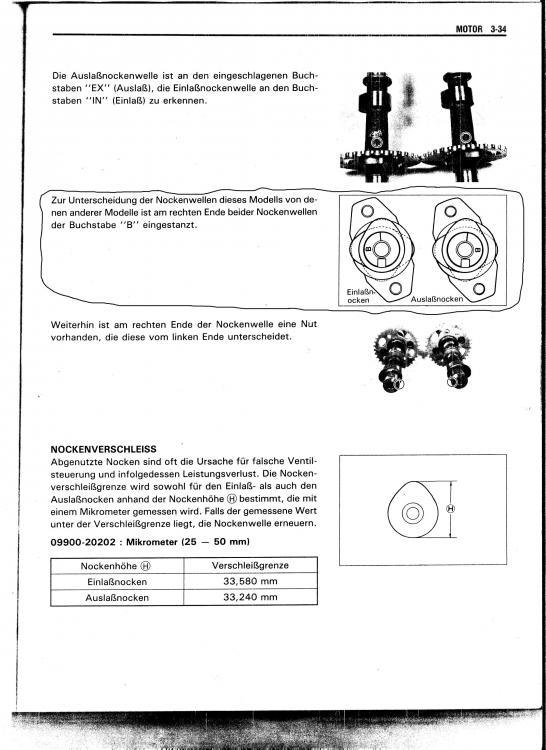

Maybe , but according to original Suzuki service manuals and my experience end side letter stamp is factory mark from main reason to distinguish them from model to model ,

for example cams with stamped letter :

A - cams from late R750M model with 8 lobes per cam

B - cams from R750J model , where R750K model have same intake (B) cam, but exaust cam is with slightly different characteristics and different letter stamp

C - cams from early R750F,G,H models

----------------------------------------------------------------------------------------------------------------------------

picture from my Suzuki original service manual for GSXR750J (1988) model (German language version)

-

3

3

-

-

Cams with stamp `B ` is from 88- R750J model (not 89 K model) , intake cam lobe height is 33,878mm - 33,918mm , exaust cam lobe height is 33,533mm - 33,573mm .

-

1

1

-

-

Arttu

I understand your concerns ,

and I think you are right , the best solution will be when each ignition stick coil have his own IGBT transistor (driver) ,

but if that original drive signal which arrive on to IGBT gate have to long dwell time maybe again some series connected power resistor can limit current via primary side and to prevent coil overheating , well need to try all these options ...

-

To use those modern low primary DC resistance stick coils with standard ingition box there`s two possible solution ,

one solution is not to tweak inside of ingition box but just to add one more power wire-wound resistor in series with those two stick coils to get that optimum nominal DCR value which is suitable and will not overload ignition box two power switching transistors , for example two stick coils in series 0,7R+0,7R=1,4R plus 2,2R resistor = 3,6R or 3,6 ohm , but must say that this solution will probably significantly reduce secondary side sparks power delivered on the spark plugs,

second IMO better solution is to use those modern low RDC stick coils but connected in parallel , in that case ignition box need to be tweaked ,at least that two bipolar junction transistors ( N-type high voltage power darlingtons ) need to be replaced with modern N-type high voltage switching power Mos-Fets , those Mos-Fets is wide available and very cheap now.

-

24 minutes ago, R1guy said:

My only advice would be lots of triangles

Of course

-

R1 guy

thanks for those pictures , it is very valuable for me since I think that can see that two rear shocks are bolted on original aluminium subframe ,

and that was my biggest concern , did original subframe is strong enough to carry and endure two shock absorber forces ? , but since by me original subframe is already chopped I think to made new subframe but not from aluminium profile but from some rectangular strong steel hollow profiles , something like 10mm x 10mm , that new subframe will be bolted on the main frame .

-

Just found one more slabby frame but is badly chopped where rear shock suspension need to be bolted , I can make and weld missing original frame parts but thinking about conversion on to conventional two rear shock simple system , did somebody already made this sort of conversion ?,

your opinions please ?

-

2 hours ago, mikeyd said:

Genius! Wondering if that could of been a problem for me when using a thick copper gasket.

Does it take less oil/lubrication when it is shim under bucket compared to rocker head?

- It depends directly from how much that cooper gasket surface is flat and smooth , in any case thin layer of quality silicone assembly kit need to be added all around of that oil channel , both between engine block and gasket and also between gasket and cyl.block , this job with silicone kit have to be done very quickly since about after half of hour that silicone become normally rubber hard .

- No big difference between ZXR 400L engine and GSXR oil cooled engine when oil/lubrication need is , only difference is that by ZXR400L engine one cam lobe via one rocker-arm activate just one valve which have just one valve spring , at least I can say that ZXR cam lobes however is less loaded than GSXR cam lobes where one cam lobe activate pair of valves with two pair of valve springs .

edit ,ZXR engine do not use valve buckets .

-

5 hours ago, Gixer1460 said:

I think we all should just agree to disagree and do whatever the hell we want to do! Please note that 'I' have never claimed they are good or bad, just that I have them fitted and that they have done no damage to my motor. If you do not want to fit them - don't and leave it at that!

Of course that I will Never fit those bypass oil hoses

Running on 3 cylinders on idle

in Oil Cooled

Posted

Yes that small O-ring dimension is 7,5 i/d x1,5mm ,

also is important to check condition of O-ring on each intake manifold boot .