Buzuki

-

Posts

181 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Posts posted by Buzuki

-

-

Important to know is that after oil jet (on each side is one jet) on each side of the cylinder block is one small oil channel which is oil flow connection between the rear cylinder stud and front cylinder stud , that small oil channel need to be perfectly sealed against oil pressure loose , around this studs pressurized oil flows up for oiling and lubrication of cams journals , cams lobes and rockers ,

for top end good oil pressure and lubrication is also very important to use brand new cooper washers on the top of this four cylinder studs ,perfectly flat new cooper washer ensure good oil sealing against aluminium cylinder head body ,

good compromise between main oil gallery pressure for bottom end lubrication and top end oil pressure and lubrication is to use oil jets with a bit bigger bore .

-

-

12 hours ago, Jaydee said:

If you are talking about head gasket o-rings, they have a metal washer impregnated in the rubber. Not as simple as normal rubber o-rings. As for the oil drain tubes o-rings? Why chance it if you have to tear everything back down again when it all goes wrong? Spend the few quid extra and buy genuine Suzuki.

Just checked both many service manuals and some old OEM cyl.head gasket six O-rings and did not found any metal washer impregnated in the rubber ,

IMHO what`s important when man have to chose some alternative O-rings is that they have to be strictly made from Viton rubber , since Viton rubber is very resistant to oils , gasoline, and what is the most important to high temperature ,

four O-rings for oil return two tubes is less loaded since there is no any oil pressure , but again they have to be made from oil & temperature resistant Viton rubber only.

-

From my experience any but quality from Viton rubber made O-rings can 100% do the job when physical dimensions is the same as Suzuki originals .

-

IMHO those carbs are in very bad condition and they ask for complete overhaul , obligatory all those internal O-rings need to be replaced , check for correct valve clearance also, and for good sealing between 4 carbs rubber boots and cyl.head .

-

-

-

When one of your ignition coil broke down that usually causes that one of the darlington switching power transistor inside of the CDI (ignition box) also is pull down ,

replacing that bad transistor (2SD1071) altogether with bad ignition coil usually is enough to successfully solve the problem .

-

32 minutes ago, Denys said:

Yes, I've already ordered another used ignition unit but it seems to me that box can either give ground to coils or not to give, there is no way that it can give bad or insufficient ground to the coils.

Just one more thing ,on the fully warm and idling engine did you try to wiggle TPS (Throttle Position Sensor) left and right and see the influence on engine idle stability ?

-

Last thing what come in my mind and can cause unstable engine run is the ignition box , so if is possible try to swap him with another original ignition box , but before you swap that box inspect his connector contacts for corrosion .

-

Denys

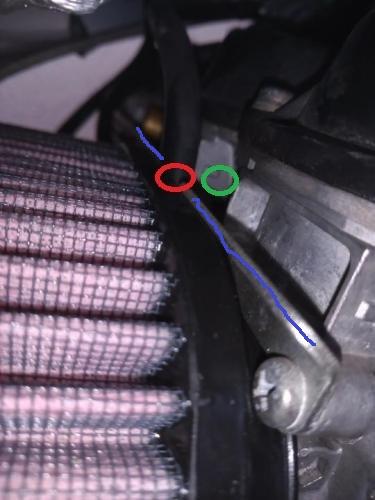

Your measured spark plugs resistance is OK but I was thinking on spark plug caps (connectors) internal resistance , which have to be around 10Kohm measured from connector end to end , picture shows internal piece order , resistor (pointed with red arrow), spring , and brass screw , that (RFI) supresor resistor sometime loose his resistance causing weak High Voltage spark , which can be bad both for engine correct run and also bad for ignition coil correct load .

ps, did you check for correct mutual position of both camshafts vs cranckshaft ?

-

9 hours ago, Denys said:

3 full turns backwards

- That`s OK , but even with 1,5-2 full turns backward your engine have to run at idle very smooth ,

- must admit that I was just once successfully repair those KeiHin CVK32 carbs on one B6 , reason of malfunction was bad float needle valves , those carbs leaking the fuel like crazy , any way just checked original B6 service manual (95-99 model) picture of CVK32 slow system schematic and on that picture tip of the pilot screw is showed flat with round inner surface of the carb throat , so I think maybe before you somebody inserted wrong type of pilots screws ? ,( from my experience by many Mikuni`s carbs from oil-cooled engines pilot screws tips never peek above inner surface of the carbs throat) ,

- further I will check with ohm-meter condition of spark plugs connectors since inside of each high voltage connector is hiding one around 10Kohm resistor ,

- question , did you check condition of O-rings which is hiding between each intake boot and cylinder head ?, since after 32.000Km and 12 years of old engine they can be in very bad condition causing false air to be sucked ruining engine idle ,

- and I guess that you close those four vacuum outlets with suitable rubber caps ?

-

1

1

-

-

1 hour ago, Denys said:

Was trying today to test needle float valves, left carbs under fuel pressure for 3 hours but haven't found any leaks, the level of fuel in the tank remained the same, so unfortunately all 4 valves look good. Another issue that I found out is that the temperature on the header pipes is different for all four cylinders. For instance: 1 - 65°C, 2 - 71°C, 3-86°C, 4-56°C, is it normal behavior? I've already ordered a set of pilot jets and pilot screws. I tried to take macro photos of pilot screws inside of carbs and one of them is a little bit smashed in the end, don't know if it can somehow affect idle revs.

Strange picture , since usually tip of the pilot screw don`t peek outside in the carburetor throat ,

question , how many turns backwards you turned each pilot screw from fully closed top position ?

-

14 hours ago, kiwisuzuki1100nz said:

Sorry a bit more context. I read the valves and or seats have a thin hardened layer and that lapping them in can wear through the layer so shouldnt be done.

Sounds like most do lap the valves in.

On oil cooled engines only exaust valves are with hardened surface , and that surface is not so thin at all , so you can lap all valves with no problems , personally I found that by exaust valves ordinary grinding paste was to soft so finally I have to use very hard diamond based paste to complete the valve job .

-

1

1

-

-

Early GSX600F engine is 10HP stronger than B6(mk1) engine (87HP vs 77HP) because 600F engine use `sharper` camshafts (C) same as from GSX-R750 slabie engine .

-

2

2

-

-

-

-

-

-

Don`t do that since is extremely dangerous to ride that fast bike with forgoten sidestand lever in open position since there was no sidestand switch to cut engine off when 1`st gear was engaged !!! , just replace that sticking switch with absolute good one .

-

-

-

-That is correct order of the needle plastic shims ,

- also you have to check condition of the O-rings which is on underside of slider guide, usually those O-rings becomes hard and bad and than false fuel being sucked in the carbs throat ,

-and also check condition of the intake boots O-rings , those O-rings during the time becomes overheated and bad , than false air being sucked in the engine , but be very careful when remove intake boots bolts , no excessive force to be used ! .

-

1

1

-

-

Those rocker-arms is all the same , check and install only best ones with less as possible wear of chromed surface .

Awesome Oilcooled Pics

in Oil Cooled

Posted