blandit600

Members-

Posts

15 -

Joined

-

Last visited

Reputation

8 NeutralPersonal Information

-

Location

UK

Recent Profile Visitors

The recent visitors block is disabled and is not being shown to other users.

-

I like your thinking! The ABS Option would be interesting, food for thought!

-

I was going to post an update soon, I've been stock piling some parts and waiting for some custom parts to arrive for the project. Really appreciate you taking the time to post a video, but very strange, the throttle bodies I have (Allegedly from a 1250), have black injectors?

-

Im going to run an external fuel pump. Drill two holes in the tank, one for the feed line and one for the return. to clarify this is technically a return system, it’s just the fuel rail is after the fuel pressure regulator rather than before.

-

I'm going to change to a 24-2, its feels more comfortable to me. Cheers all

-

Sorry Arttu, I was hoping to use the stock 650 injectors, but I'm trying to find out what injector size they are, would you know?

-

Yeh I was worried about it keeping up in the RPM range, but I wonder if the 36-1 has been tested at 10,500rpm? Yes I originally wanted a "Return" fuel system, but weighing up pros and cons, the "Returnless" system will be absolutely fine and then I don't have to faf around with a new fuel rail too.... My original "Christmas list" is dwindling haha but trying to stay on track! Still after the injector size for the 650 though if anyone knows!?

-

Another small update: So I've been 3d Printing some various test parts before machining.... First up was the crank trigger: So I've opted for a 36-1 trigger wheel for optimal resolution, but I was curious as to whether the sensor will struggle with this resolution / feedback due to the small size of the wheel? Would a 24-2 wheel be better? I'd be interested to hear peoples thoughts. Next up was the fuel system...... So here's the plan. I'm going to blank off the Petcock hole and then drill two new holes for the fuel feed and return. I've tried to incorporate either the inlet / outlet or both onto the Petcock block-off plate, but there wasn't enough room to comfortably accommodate it, so Ill drill those elsewhere on the tank. Again just 3d printed the block-off plate for test fit before I get it machined (I'll have an o-ring groove machined into it for sealing): I'm going to stick with the "Returnless" fuel system from the 650/1200 as I don't fancy getting a new fuel rail sorted, and run an adjustable FPR. Lastly, would anyone know the CC size of the 650 injectors? Struggling to find that info online.

-

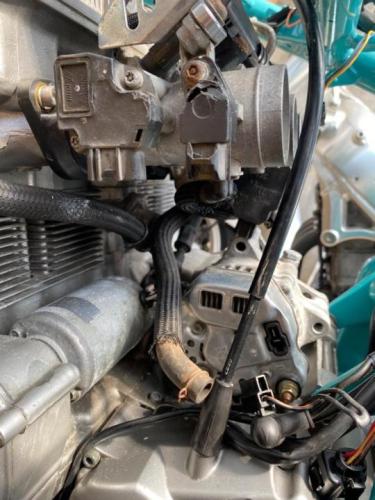

Update: So.......I broke the GSXR 600 K1 ITB's I had..... some of the screws holding the butterflies on sheared off frustratingly.....But I think this was a sign. Talking to a few of the forum members, I ended up buying some GSF650/1250 ITB's (they both have the same spacing, just different injector size) and be done with it and they fit! near perfect, with a few issues: So, using some GSF1250 Rubbers, a bit of grease, they fit. I would guess the spacing is off by 2mm using these rubbers, but I don't think Ill get much better than that. I plan on using some rose joints with adjustable hex bars as a sort of linkage? to help really secure the Throttle Bodies to the engine, but Ill wait until I've sorted out the fuel pump and petcock block off for how much space I've got to work with. As I originally mentioned, I wanted to use the secondary butterflies, but the where the motor connector connects, it would foul on the alternator, so I may have to give this a miss for ease sake. Overall, other than wrecking a perfectly good set of 600 k1 throttle bodies, I'm happy with the progress so far. Thanks for everyone's input

-

the thing is, the swingarm is symmetrical, which I quite like, is a tough one, either get the swingarm remade with an offset in it so I can use the original spacers? or keep it symmetrical and just use different spacers? I had it custom made (not many places to get an extended swingarm off the shelf for an SRAD!) and by the time you take postage costs into account blah blah ill live with the spacers. IF the wheel was off by 10+mm then this would be a different story. Drag racing / extended swingarms is a whole new world for me! so lesson learnt for me, next time ill be more specific in my requirements. Thanks all

-

Thanks, yeh I've checked this out, so the outside face of the sprocket carrier is the widest part of the rear wheel assembly, so If I wanted to get REALLY into it, I would remove the bearing seal and mill the sprocket carrier face, then if I needed more, then cut / shorten the sprocket bolts etc etc, but for 2mm? its A LOT of work for someone without access to a mill or lathe etc etc So I'm going to roll with the 2mm offset, see how it feels, and go from there Cheers all!

-

Hi all, I've been slowly building a GSXR 750 SRAD on the side for drag racing, slowing but surely its coming together. It's nothing fancy, just dipping my toes into the sport and I had a spare frame, engine, forks, wheels etc etc lying around, so thought why not? I've had an extended swingarm made and it looks great, ticks all the boxes, happy with the dimensions & quality. However, the original wheel spacers no longer space the wheel to where its symmetrical with the bike and is offset approx 11mm to the right (looking from the rear, facing forward. I've had some wheel spacers made, which now space the wheel as far over as it could possibly be, before I it clearance issues with the sprocket carrier rubbing against the inside of the swing arm. This new spacing brings the offset back 9mm, so the wheel is now 2mm off the centre line of the bike. I have measured and re-measure the dimensions from various points of the frame in relation to the rear wheel before writing this post and to the best I can make out, the bike is "Straight" and the engine / swing arm centre pivot has be torques in the correct sequence to space things out as they should be. So my questions is, will 2mm be noticeable? is this sort of normal, in the sense that are any motorcycles with an aluminium twin-spar frame "Straight"? I'm assuming perfect mm alignment is usually not something that is achievable? or am I wrong and this will effect the bike pulling to one side in a big way! Hers a few pics of the project! As always, thank you for reading and some opinions would be appreciated!

-

Thank you for your replies everyone, I appreciate you all taking the time! So the Bandit 650 Throttle Bodies are 42mm OD on the inlet side, only a couple of mm difference to the K1 bodies, but again still larger than the mk2 600's 38mm OD, and the 650 bodies have a spacing of 80-100-80, so to make those work I would have to shave 15mm off the centre section, which would be very difficult as all the throttle linkage and secondary motor is in there, If memory serves me right its also a return-less fuel system which isn't ideal (debateable, but from my personal experience I would want the return), and just in case anyone else picks up this thread in the future, the 1250 throttle bodies are the exact same spacing, ID and OD of the 650 Bodies, they are interchangeable (I would guess the fuel injectors are different though). The reason I like the K1 bodies is the secondary butterflies. Even though the bore size is larger on K1, I'm planning on using these secondary Butterflies to tune out some of the air inrush to create a better velocity and varying RPM. I dabble in electronics, PCB Design / microcontrollers and ECU architecture, and I'm doing this as a hobby / challenge. I love the 600, its was the first big bike I bought 16 years ago, its comfortable to ride and not fast enough to get you into serious trouble ha, I was fed up of the carbs requiring maintenance all the time as I don't get to ride it as often as I would want, and Its missing some modern comforts..... Not only did I want to make this EFI, but I wanted to add: 1) Secondary Butterflies - Better throttle response, more tuneable power curves etc etc 2) Launch control - I'm heavy into drag racing too, and thought this would be a bit of a laugh 3) Flat shift - I'd like to add a strain gauge, essentially a quick shifter, but instead of adding an additional ignition cut box, I'll let the ECU handle it. 3) Switchable maps - This may end up not being used, but I want to experiment with higher octane fuels. I may just go flex fuel, but with the map switch I can also look at fuel economy or power reduction for the colder months, etc etc. 4) Traction Control - I feel more confident riding my more modern bikes in the winter months as they have ABS, wheelie control, traction control etc etc and Traction control will be the easiest to add, a couple of wheel speed sensors and were good to go. 5) Reliability - As I don't get to ride much, when I do want to jump on this bike, I don't want the hassle of whether its going to start 1st time? or if its not running well etc etc. I originally started this thread just for a couple of answers, but I may as well keep this going as a reference for the project? I don't see the 600 get a lot of love, but I know it has a little potential and it I know I'll enjoy the project. Sometimes projects don't have to be about cost efficiency haha Here's a pic of the bike when it was running on carbs, no exhaust on it for some reason? can't remember why........ Cheers all

-

Thanks both for your replies, much appreciated! So my theory may be right then? If I popped 1200 inlet rubbers on a 600 head, the spacing would be narrower in theory, this could still work, as the throttle bodies I have selected are individually bolted together, I can machine them down, a pain, but doable. Has anyone ever tried squeezing 44mm stubs in a 1200 inlet rubber? or is that just not going to happen? Thank you.

-

Good evening all! Hoping someone may be able to help!? For the past week I've been trawling through forum posts about carb spacing and inlet rubbers for various oil cooled motors, however I can quite find the exact answer I'm looking for. I have a MK2 600, and it has some sentimental value to me (I have other bigger bikes, but this one I wanted to keep as a 600), however I don't get to ride it much and I wanted to add a few modern touches! So I'm in the process of doing an EFI Conversion, so far going well, however my plan was to use GSXR 600 K1 throttle bodies for the intake (no problem there, they are individually bolted together so can be spaced appropriately), the spacings are the same for the outside, but the inside needs widening 5mm, no problem. So, the GSXR inlet side stubs are 44mm, and I'm trying to match up some rubbers I can use to match these OD's. Now I've found a table which has been posted on this forum of various carb combinations, but what I cant find is whether the rubbers are offset? So for example, the MK2 600 carb spacing is 80-80-80 and the MK2 1200 is also 80-80-80, but....if you were to put the MK 1200 rubbers on a MK2 600 head, will the spacing be different? i.e are the cylinders spacer wider on the MK 1200 and as such the carb rubbers are offset to compensate? or are all the cylinder spacings the same? I don't have any MK2 1200 parts to reference, so I was hoping someone on here may be able to assist! Thank you.