-

Posts

53 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by MotoRoboto

-

Yep. The ones I got got are the latest versions so should be much better. Those early ones are so blunt and basically as cast it's not surprising they fail so easy.

-

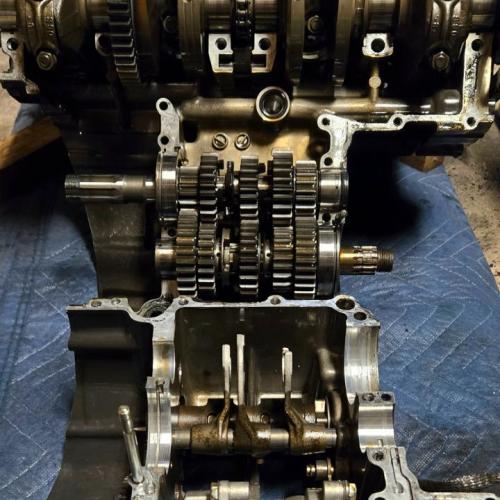

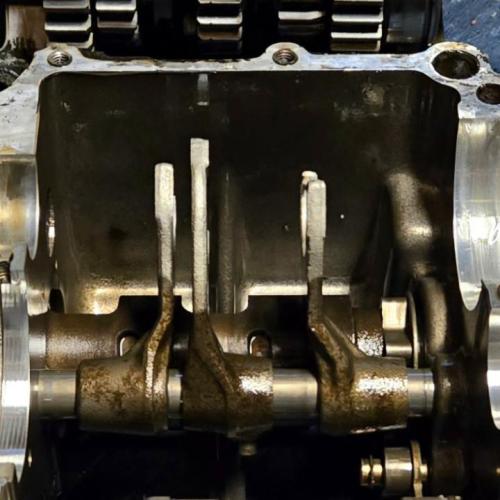

Just going through the trans. Was expecting more damage. Shift arms look decent but will double check. Got some new old stock 2nd and 5th gears. Putting the Factory Pro dentent arm and stiffer spring in while I'm in here.

-

Ok. Will check those. Thanks for the info!

-

Will be sure to check. Thanks

-

Yeah I'm amazed there's anything left new. 2nd driven gear is obsolete now.

-

The shifter linkage was a bit balled up. I reset it so it was as it should be. It shifts much easier and cleaner now. The lull/surge still occurred but it was way less frequent and severe. Also noticed as I adjusted the clutch lever further out the frequency and severity lessened even more. Wondering if the '90 1127R push rod isn't long enough. The stock '86 750 pushrod was way too short. I"m using the '86 750 sprocket cover with the '90 1127R pushrod. I've heard mention of needing to find the right length pushrod when doing a 7/11. Anyway, not gone but much less severe. It's almost livable for the time being. I just got done doing the swap and don't feel like doing that shit all over again just yet.

-

Yeah that was the original prognosis and plan. Was curious if forks or cogs or maybe something else. Also wanted to check the linkage suggestion above.

-

I've thought about getting the Factory Pro detent arm and stiffer spring. If it's not the actual trans this is said to help make shifts cleaner. It's a '90 1127R motor with the stock '86 750 shift linkage but the clutch push rod from the '90 1127R.

-

It's a '90 1127R motor in an '86 750 frame with the stock linkage from the '86 750 but the clutch push rod from the '90 1127R.

-

Will do. It is more difficult to shift into 2nd gear than the rest. It's also just generally more difficult to upshift period. Downshift seems normal.

-

So of course the donor motor for my 7/11 has a wonky 2nd gear. I know I will have to fix it. That being said... Basically runs great but when in 2nd it will do a neutral like lull and then surge and rest of 2nd is normal. The lull/surge happens within less than a second. Maybe half a second. Doesn't fully pop out of gear. Tach is also acting up but I would have to guess it happens around 5k rpm with casual acceleration. Does anyone have any experience with these symptoms and what it ended up being more precisely? Just curious about others experiences with it and what it was. Have done a lot of searching but the actual damage is rarely covered.

-

That's good to hear. Oddly the cams that cam out of the engine had slotted sprockets but were so far off I went back to stock. Maybe some winter I'll put them back in.

-

That was my next guess from what I've read about that head. I'll look into that. It's currently running with no abnormal noise.

-

I looked into that and the cam sprocket part numbers are all the same. Changing sprockets made no difference in slack. Maybe the d0thead is slightly taller. Edit: Scratch that, yes they are different but I got some stock 1100 cam sprockets just in case. The cams are from a d0thead 750 BUT they were in the 1100 so I'm assuming the adjustable cam sprockets were correct for that engine. Either way I didn't use them and the stock ones provided the same slack.

-

D0thead and cams. I put some stock cam sprockets on it and same situation. My guess is just old engine was really worn out.

-

It's flipped. Had three manuals. A factory manual, an old first gen only Haynes and a first thru third gen manual. I ended up pulling the cams and holding the cam chain while I rotated engine to make sure it was on crank correctly and not kinked. Put cams in while holding cam chain taught. Redid everything. Slack was the same. Just how it is I guess. Spun fine later when more fully assembled.

-

Hello, Just installed cams in the 1100 I'm using for my 7/11 project, will have updates later, and there is zero cam chain slack. 22 links, arrows where they need to be, grooves at end of cam in proper position, rotor lined up, idler installed. Turns over by hand reasonably well. When I pushed on the chain guide thru the tensioner hole there was no play at all. The '86 750 that was in it was high miles and had a lot of slack after cam install. Maybe this is just a good condition cam chain and I'm not used to it? I can't help but think something isn't right tho. Run out of ideas. Any suggestions on things to look at?