jacktar01

-

Posts

87 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Posts posted by jacktar01

-

-

On 14/10/2017 at 12:58 AM, boilerdude said:

Ok so I got my wheels back from the machine shop (having nothing done yet). And took some quick measurements you can believe me or not. With the efe sprocket carrier in the efe wheel and then efe carrier in gsxr wheel. 3mm most certainly does not need added on to the sprocket side spacer. There is approximately a 12.5mm difference to the center casting mark (not the most precise I know but it's there anyway.) and it is of course naturally the gsxr wheel which is a further distance. So approximately 12.5 mm needs cut off from the sprocket side by my measurements. (and the carrier hub itself will also need cut into. And also the sprocket bolts will need cut down to avoid fouling the swingarm. Just as with the gsxr carrier (or just pull them in with shims))

So now I wonder what carrier may offer more room yet. teapot 1100 perhaps. slabby. 88-89 750. I have the latter 2. gonna try and measure those up over the next few moments. Or perhaps I should just pick up a file and start shaving down my own spacer and then the actual hub and each of the sprocket bolts until the wheel is properly centered.

Perhaps I could have the cush flaps and rubbers cut down And that inner spacer. bring it in that way. just a thought. The spacer would be the first thing. and then the flaps and rubbers merely need to fit firmly afterward.. I doubt there is clearance for the chain to the tire with this method.

It really is starting to look like the best way to do this clean and proper is (bandit) swingarm swap with the upper shock mount welding.

Glad your getting there and I did say you would be best direct measure everything as it was a few years ago and only remembered making a spacer up, but I never had to machine the carrier or wheel and the EFE carrier cleared the extended swing arm using standard unfettled parts..... mine all cleared probably because of the extended swing arm pulling everything backwards ... you got the way ahead now so happy days

-

Happy Families all again around the world ......

Dlindberg,

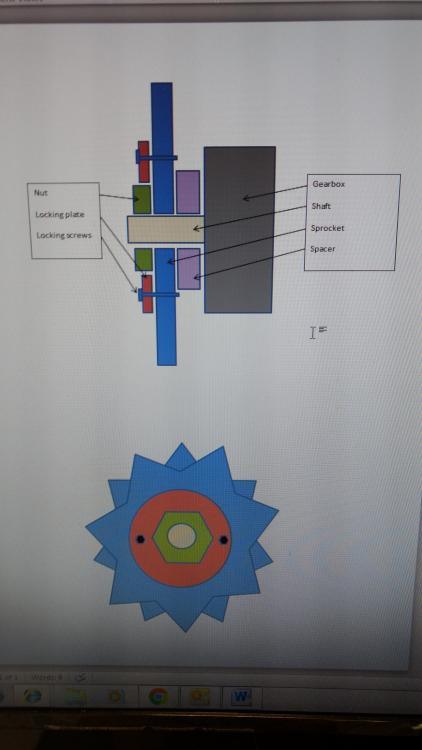

1. Correct I made the locking plate fit onto the pre drilled screws on the front sprocket, but a replacement 1 tooth bigger steel sprocket came un- drilled

2. The offset Kwak sprockets were an option but I already had EFE standard gear.. and I am a tight-wad ha ha

3. I didn't machine anything off the sprocket carrier just made a new new swing arm to carrier spacer using direct measurement and presume it was around 3mm wider

4. Similar sort of process for the brake side best use GSXR Hanger and calliper just fit it all on and direct measure spacers needed, I didn't have that so scratch made a hanger using the forge at work, bit of lathe work, bit of welder, and a bit of milling and all good.....Egay hanger and calliper next time ha ha

Boilerdude

1. You will need to direct measure the Carrier spacer needed as I presume its around 3mm wider cannot exactly remember, but I did make a new one up using a bit of stainless bar

-

1

1

-

-

There are loads of ways all correct this is one way of doing it that uses standard 630 sprockets and chain, I used a GSXR 5.5" rear wheel with a 180 tyre in an extended standard swing arm. The home made locking plate allows the use of an 8mm spacer as the gearbox output shaft nut will only have around 1 thread showing without the tab washer.

-

1

1

-

-

2 hours ago, vizman said:

ironically that last pic is 'align left'

Abuse getting like the old site ha ha if it's my pic mate outwards from the sprocket is left ......I think if that's ironic

-

1

1

-

-

On 26/09/2017 at 12:43 AM, boilerdude said:

but the swap already calls for an offset front sprocket. It would likely put it closer to just right I assume. In fact with the efe drive in the gsxr wheel the sprocket alignment is guaranteed to not need any modding in the front. But I hear what you're saying. the subframe is the part thats "not where it should be". Probably tipped over at some point and was perhaps fixed up again nice and original like with long turn signals and everything. But on the other hand it does seem otherwise original and not layed over. The turn signals are cracking into a hundred pieces like I'm sure you guys know they do over time. but still hold true.. but still though. Do I take it somewhere and get the frame straightened. Or just install the wheel with the efe drive and see where that puts the wheel on the bike.

nah thats probably silliness. I need to just get the wheel centered to the arm and then get the bike straightened or not ...

I have both rear wheels at a local machine shop. Ive commisioned them with measuring from the sprocket side spacer to the center of the wheel on both wheels. figure out the difference. then the efe carrier swaps into the sling/bandit wheel (which improves clearance) and then take measurement again on the gsxr wheel. figure out how much closer to correct that gets the wheel and then take the remaining bit off of the efe spacer. I suppose the ball is already rolling on that.

So dont worry it's getting done the right way I suppose

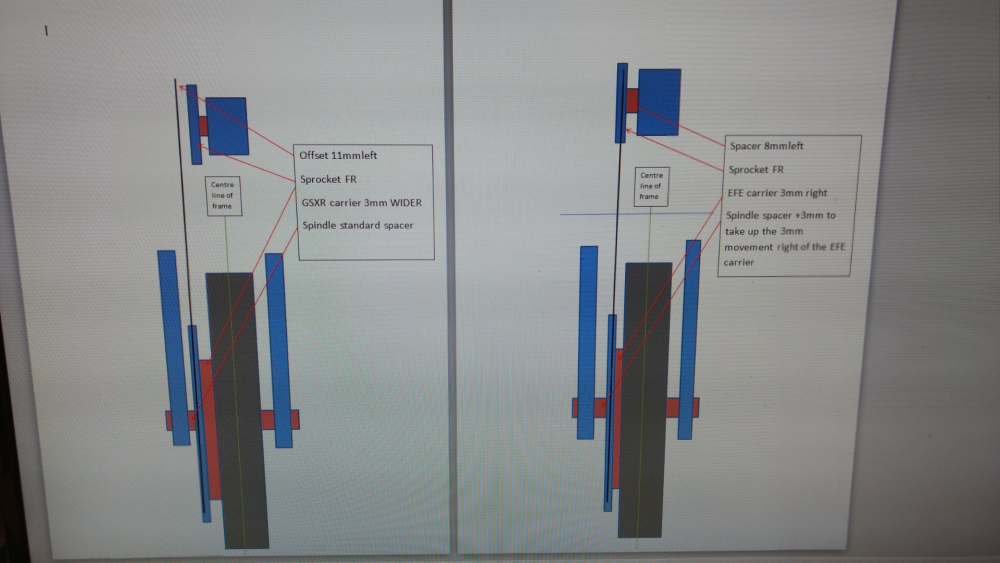

when I fitted an GSXR wheel and carrier the offset was 11 mm outwards on the front sprocket, I got this with EFE Carrier 3mm inboard towards the wheel and an 8mm spacer on front outwards towards the frame =11mm all runs straight and true on the bike mate. The shaft nut sits nearly flush 1/2 thread showing so I made a locking plate and cut a hex out the middle the drilled and threaded two holes in the sprocket to lock the plate to the sprocket so the nut cannot undo. Meant I could run all the 630 stuff I had.

-

1

1

-

-

Looking smart mate.

-

I did have to polish the aft face of the coil with a file to gain the fag paper clearance needed, a gap is a gap for MOT...but not enough to cause snags. Think I picked my Shock up for £20 of egay

-

1

1

-

-

19 hours ago, boilerdude said:

could possibly rub at full extension you mean. Or you mean if I come down hard and bottom it out it may rub.

pretty sure the vtr1000 was largely unchanged throughout its production run. could be wrong but I bet theyre all the same.

The spring clears the swing arm opening as it compress under load, you sitting on it opens up the gap due to the geometry of the levers, spring moves fwd... and could rub on the opening if the swing arm has no load at all allowing the arm to drop and the spring move aft...jumping hump back bridges.

-

Vtr1000 around 99 if I remember , you had to trim the end in pick 1 by a few mill either side to fit in the bracket fork, bottom end pic2 straight fit and pic 3 shows the spring runs really close to the swing arm think I polished it a bit ha ha but the geometry clears as the shock compresses and could possible rub if you jump hump back bridges ...

-

1

1

-

-

I used the extended link until my standard shock became unserviceable so I used a Hon#£ VTR shock bought cheap on Eblag, has two eye ends but the top one needed trimming down to fit in and the spring is very close as it passes through the swingarm. The shock bolt is in shear and uses the same bolt so in my opinion no reduction in safety. Been on a few years without snags, and the back end sits a little higher on a standard link

-

1

1

-

-

Will get a few pics tonight mate

-

1

1

-

-

I got a few old gsxr fuse boxes in my Garage mate will get a few picks..you might be able to salvage something

-

1

1

-

-

On 10/02/2017 at 7:52 AM, Rene EFE said:

What R/R did you end up using? As I understand it, all of them are pretty much the same, I just can't get my head around using one of a Superdream, which is supposed to be the best one.

I used a Super dream one that cost a fiver, it has an extra live to blank but its been working fine for the last few years now. Funnily enough a mate who likes his H*nd£s informed me they were a common failing on the Super Dreams and consider junk ha ha

-

https://www.ngk.de/en/technology-in-detail/ignition-coils/maintenance/diagnosis/ lots of advice and info mate

-

Good to know about the Triumph calipers will keep an eye out for a set

-

Another issue with ultrasonic cleaning is some people do not use the correct carb ultrasonic cleaning solution, the difference is massive when it comes to the cleaned product

-

My wife thinks every bike I have ever bought has always been a bargain as a non runner around £200 - £400 mark........... ha ha

-

1

1

-

-

Oh I will get some popcorn Trading in the Aircooled section ha ha ha.........

-

Welcome aboard mate

-

I like that idea mate, but i would be tempted to strip the KOSO down to and fit that into the original dial with an overlay transfer on. A lot of work and risk damaging the KOSO but you might be the first to do it........Ha Ha

-

Looking good with lovely fabrication

-

1

1

-

-

Would have thought the ignition side cdi, pickup, coils would be compatable with most looms. I can confirm after 6 months chasing an intermittent starting issue on a chop project i bought that GS750 CDI's will randomly fire up but are not to on GSXR' engines ha ha

-

Looking like a nic build project keep the pics coming

-

Who would of thought ''home and away'' and ''neighbours would get a mention on OSS........not in the old days ha ha

-

1

1

-

gsx1428 streetable?

in Air Cooled

Posted · Edited by jacktar01

update

I remember an Aussie Chap on the old site having a set up that some old engineering mate of his was regularily buiding using standard heads, 1100 gsxr sleeves(bored to take Mk 1 Busa piston, are the small ends the same size ?) into EFE Barrels, think he bored the cases and added a thicker base gasket and after being told it shouldn't work, he showed all the pics and the calculations and other stuff his mate was building into EFE's like auto box and 1500cc........Or is dementia kicking in...definitely an Aussie though