NipsuGoesRace

-

Posts

11 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Posts posted by NipsuGoesRace

-

-

Mtc crown thickness is 5.0mm

Stock gen1 Hayabusa also 5.0mm

Je piston 5.6mm

I little suprissed how thin that mtc crown area is, because they are pretty massive design and they also are 55 grams heavier than Je and 60 grams heavier than Hayabusa stock piston.

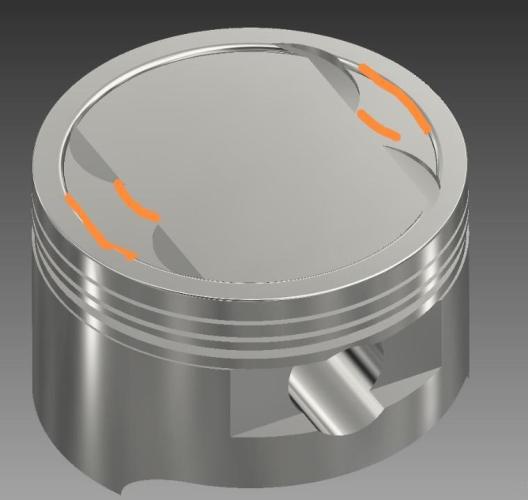

Round type is the easiest and chepest to get machined, but i'm worried about these orange section. If the bowl is 1.25mm deep and squish is 1.00mm there is 2.25mm between head and piston on those areas. Is there increased risk of detonating on those areas?

-

-

Yes these are 10cr Mtc pistons 8.8CR, only needed 1mm base gasket under the cylinder block Mtc piston valve pockets 0.7cc

Head chamber 28.5cc

1.9mm squish 9.8cc

Cylinder Volume 304cc

343/39= 8.8cr

That 1.9mm squish band probably isn't optimal by the book and thats why I think that have something to do with that piston ring damage. Thats why I would like to have that bowl machined to the piston. And I hope that also prevents piston rings to get burnt. Hayabusa JE turbo Pistons have that round shaped bowl and it's about 4mm deep. But if that same 69mm diameter bowl machined to these gsxr1100 Mtc Pistons it only can be 1.25mm deep because the head chamber volume is so large. And I want that CR won't change too much. So is that round shape only option or can that bowl be more like a Square, same shape like the head chamber? Thats why ask if that stock piston dome shape, can also be shape that bowl? And if not why? I haven't found any picture those MTC 8:1 CR Pistons with the bowl, if some one have, i'm interested to see that design.

-

-

Idle 70-75 kPa or -9 to -7 inHG

Cruise 85-90 kPa or -4.5 to 3 inHG

Engine braking below 60 kPa or -12 inHg

-

1

1

-

-

-

Stock head's intake flow is about 90-95 cfm at 10" of water at 8.8mm lift and ported it's about 25-30% more. 30mm valve can add another 10% more flow. Difference between 30mm and 31mm valves aren't significant and 31 mm valve doesn't even fit very well to the stock valve seat. Stock exhaust side is about 80-85 cfm at 8.2 mm lift.

-

1

1

-

-

- Now I finally got the clutch out. Fibers aren`t weared at all, they were between 2.52-2.57mm. Steel plates also looked good, straight and flat. Inner and outer baskets seems to be like they should be. Lock up air cap was 1.9mm so there was an error, it should be 2.5-3.1mm, but the extra arm weight may compensate this? My clutch push rod is 104mm long, so it is a little longer than it should be, 89-90 pushrod was 100 mm and 91-92 was 101.5mm. But it seems to be okay with a bandit sprocket cover that I use, it fits nicely to it`s place without bolts. Maybe I`ll chop the rod a few mm, just to be sure. The oil I used was mobil delvac mx 15w40 and there was too much oil (max 1L) in the engine when the clutch was slipping for the first time. Winter is coming, so now I have six months time to solve this.

-

Need to check these things. Thanks. If I need a new clutch plates, is there any benefits buy something aftermarket product like a Trac King or is a suzuki oem the safest choice. Both clutches price range is almost same.

-

Hi guys, I also need an advice with this same clutch issue. I have a boosted oil cooled Gsxr 1216 with mtc 2 stage lockup and on last dyno session clutch started to slip first at just under 1.4 bar 9000 rpm and after that I put more weight to the lockup arms. (Change was m6 16mm bolt to m6 30mm and 4 washers to 6 washers). Next dyno run and clutch was slipping again, another try and warm clutch hold the run 1.45 bar 340whp at 10000 rpm. Now the clutch lever is so heavy that I can`t press it down above 7000 rpm but difference between slipping line is just margin between these two setups. Is there any benefit put more weight to the lockup arms? Or should I try something else, like put more diaphragm springs to a raise clutch spring load, I have now two barnett heavy duty springs there and the clutch friction plates was relatively new.

Gen.1 750F cams in bigger engine

in Oil Cooled

Posted

I have made some cam comparison with a engine analyzer software. If I remember correct these early gsx750f have same cams than gsxr750 85-87. Analyzed engine specs was 1216cc, 28.5mm in and 26mm ex valves, flowed head, 9.7cr, 42mm throttle bodies and open headers. gsxr750 1990 cams are gsxr1100 89-90 inlet cam and 750 85-87 exhaust cam.