-

Posts

191 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Posts posted by Goo'Roo

-

-

-

10 hours ago, rerb said:

ooh that curve looks very nice. May I ask why you went with a 20g as opposed to a smaller turbo?

Looking into it, getting an ignitech CDI seems cheaper and better than a dyna2000, something I want to do this winter. How big of a pain was it to install? the dyna seems very simple without the need of a custom triggerwheel, and lets you keep kickstand switch function. Are you running stock coils too?

I used the 20g because I had it from a proboost kit.

Ignitech is very simple, comes with the wiring adapter, but it's anyway really easy to wire and setup.

Stock triggersystem works and you can maintain the switch off safety system and add a killer switch too.

With a gear switch you can activate the quickshift too.

I used the green Dyna coils.

-

Kinugawa has mitsu 1-3 td05 turbocharger like your with ball bearing, and billet compressor. That should help a lot.

-

1

1

-

-

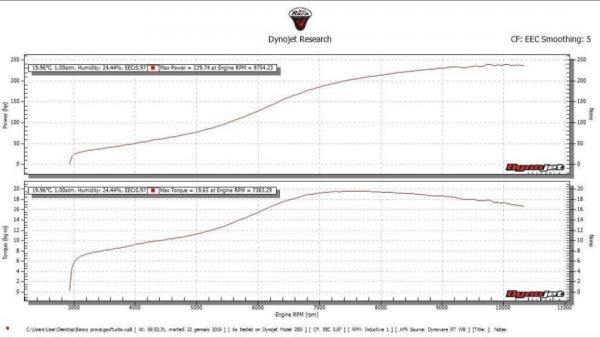

My experience with a similar setup:

Busa pistons, 0.5mm skimmed block, Chinese cxracing td05-20g turbo (a really slow spoolup turbo actually), ported gsf1200 head, gsx1100f cams, ape studs, 36mm carbs, big volume, dual chamber plenum, Ignitech CDI mapped with map sensor, and I made 240bhp at the wheel with 0.8 boost of pressure, that I consider pretty good values considering no intercooler and the "low" boost pressure.

-

4

4

-

-

You need the smallest turbine housing to get some decent spooling time.

-

1

1

-

-

I don't think 12 of afr on an air-cooled engine is a good idea. I destroyed one cylinder head trying to stay close to that number.

I would suggest a much safer 10.5-11

-

1

1

-

-

6 hours ago, Fredrik_Steen said:

You can use the stock wheel with Maxxecu. But you need a VR sensor.

Why use ignitech ecu instead of only Maxx?

I have both ECUs, and I have to do two different bikes.

-

1 hour ago, Arttu said:

I don't know how it works with Ignitech but with MS1 the reference teeth had to be before your highest ignition timing. Meaning if you want to use maximum 40° ignition advance then the reference tooth must be at 45° BTDC or earlier. But preferably not too much earlier since that would increase timing error.

I have to send them an email to ignitech, tonight I'm going to start studying maxxecu software.

Thanks Arttu

-

10 minutes ago, Arttu said:

What? I guess that's some ECU specific stuff?

With most of the ECUs that I have played with you just enter angle of #1 tooth and angles between the cylinders. Then the ECU will handle the rest to get desired ignition timing. Old Megasquirt 1 was an exception where you had to fill in reference trigger tooth numbers for each cylinder within certain window from ignition event.

Ok, ignitech is still like ms1 then.

I understand now why I was so confused.

-

Nice reading for tonight, Thanks Arttu.

So for example in a 24-1 like an Hayabusa gen2, with the missing lobe at 100°, considering a tooth every 15° would you use tooth 30 to start advance cylinder one with 10° of base advance? Or would you choose the 29 with 25° of base advance? With base advance I mean the distance between the tooth of the cylinder you're considering and his TDC -

Hello I can't figure out how properly draw a 24-1 or -2 teeths, that I have to use with maxxecu and ignitech ECU.

I've measured that the center of the spline on the crankshaft is offset by 102.5° before the 1-4 cylinders TDC.

Now I have a couple of questions..

-Where do I have to locate the missing teeth? Just before teeth n.1?

-Does usually the ecu consider the midpoint of the teeth crest while reading or the first edge that encounters?

-How many degrees before 1/4 cylinder TDC shall I place the first tooth, considering the second question?

Thank you all

-

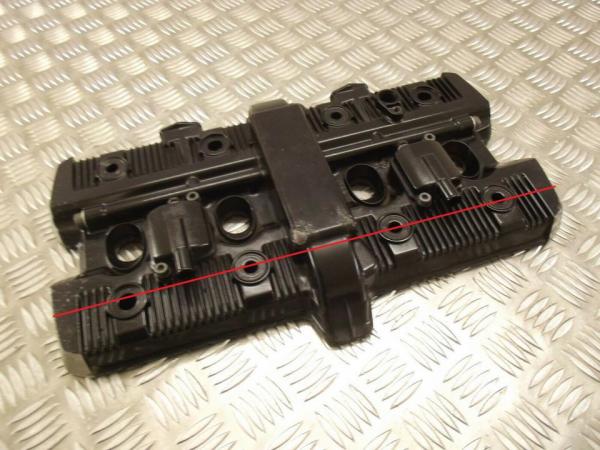

The long stroke one in the Gsf750 mk2. It has bigger valves than your B6 and fit straight.

-

1

1

-

-

-

Thanks, that's more than enough.

Rebuild the subframe is not a problem, I've issues in the rear part of the cam cover because of the twin spar frame

-

1

1

-

-

-

1 hour ago, Cheeky4648 said:

1200 bandits have a big weight mounted between the coils up by the head stock as an anti vibration aid. Maybe something like that would help.

I tried with one and then 2. Doesn't feel nearly any difference.

-

7 hours ago, VJ said:

Sounds like you've exhausted a lot of options. One other one that comes to mind now ive thought about it, have you balanced the carbs recently?

I have a motorbike workshop in Italy and they're my bikes.

Doesn't have nothing to do with carbs and so on. Simply at some revs if you keep all the super extra heavy stuff of the stock one mounted or after 5500rpm if you eliminate 30kg as I did on one of the 3, the frame and everything attached to it start to vibrate violently like a diapason. -

-

Ok you've convinced me.

I tried to reduce 11f frame vibes with no success and I was searching other solutions.

Clip on and weight at the end of the bar are 3kg each on 4 rubber mounts and it's just acceptable.

Vibes just destroy everything on that bike.

-

I need a G engine, or at least the cases.

I've checked the gearbox bearing/needle roller measures comparing them with an 11F engine and they are the same until the last one that exit the case on the secondary shaft that is much bigger: 40x80x30.2 for the G and 25x62x19. Totally different on the drum side.

It would be interesting to try to fit a F/R gearbox building a flange at the exit of the secondary shaft.

I'm going to search for an engine soon -

Do you know somebody that has modified the G shaft engine into a final chain transmission?

I'm interested in that engine because of the balancer shaft. Gsx1100Fs die because of vibrations, so It's just an idea. -

http://www.siemensdeka.com/product/60lbh-siemens-deka-high-impedance-short-style-with-ev1-connector-fi114962-37-5mm/

I think that they're perfect for my application. Very very compact

Specifications:Coil Resistance: 12.5 Ohms / High Impedance / High-Z (No ECM driver modifications required)

Static Flow Rate @ 43.5PSI ( 300kPa ) w/Gas: 60 lb/hr = 630 cc/min = 453 g/min

Static Flow Rate @ 87PSI ( 600kPa ) w/Gas: 85.7 lb/hr = 900 cc/min = 648 g/min

Gain: 0.11ms/mg Offset: 0.055ms

Turn on time @ 14VDC: 1.14ms

Turn off time: 0.85ms @ 600KPa

Connector: Minitimer EV1

Series: DEKA 4 ( DEKA IV ) Orifice

Type: Multi-orifice Spray Pattern: 30 Degree Spray Cone

Factory fitted with Viton upper and lower o-rings 37.5mm end to end, 14mm oring

-

1

1

-

-

On 9/18/2019 at 8:28 PM, manden said:

Look at the siemens deka 5 injectors. Low latency and dead time. Developed for turboed motorcycles and fair priced at around 70$ each flowmatched and new. The one I've used is 800cc at 3bar. I don't know if there is other sizes.

Do you have a link or a code? Just to understand the injector family and if they're suitable for my application

-

On 9/13/2019 at 2:32 PM, K.H.I said:

Rake the front out.... Or just fit a 17" wheel.

No way

I'm going to find the way.

It must remain oldskool

Wossner 1340 Pistons B12?

in Oil Cooled

Posted

Unfortunately not. Is a friend of mine that did 184bhp at the wheel with premium unleaded 100ron petrol. But it's the only pic I have of the engine