-

Posts

604 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by Danm54

-

There is map compensation but being draw through I don't think you can tune it with no boost. There is acceleration fueling though so if I use rpm/map I can add fuel using the tps.

-

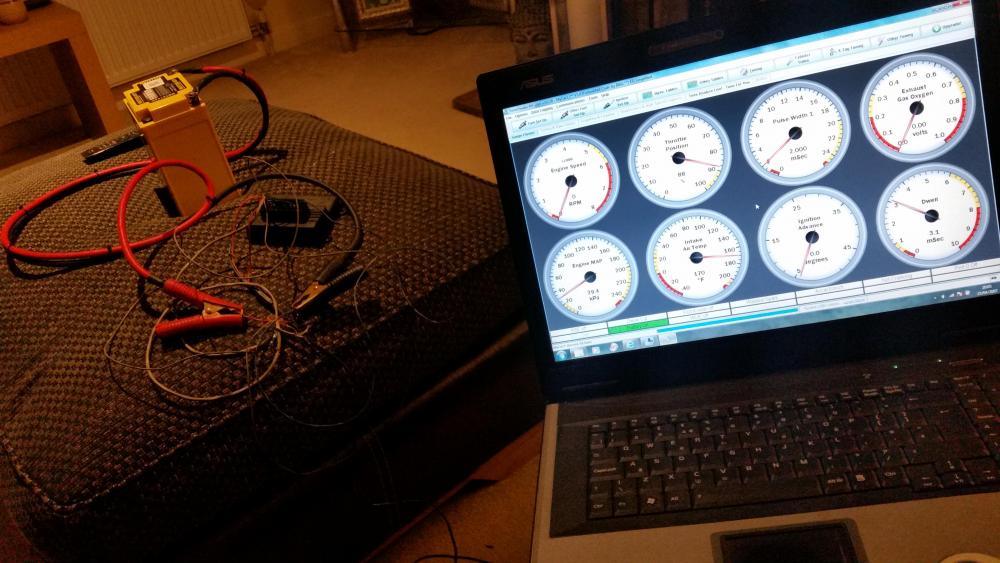

Bit of an update as its been a while. I dropped it round the dyno place and left it there for him to play with, his dyno broke though and he's not been able to get it fixed all summer. I've been mega busy with work so not really had time to do much on bikes anyway. Picked it up the other week and started going through it reminding myself what needed doing. I'm sure that using rpm/tps isn't the way to go, its fine it you accelerate from a low rpm but if you ease off/drop down a gear then accelerate it runs massively rich until the turbo picks up. I've read through the ecu manual and changed it to rpm/map. Its running on that now so I need to get it mapped. It will auto map for the finer tuning but I need a dyno to get it close. Also need to get a new boost gauge, will get a glycerin filled one rather than the electric one. Need to get the alternator looked at as well, will send it off in the new year. And finally, nearly threw out the old ecu, thought I'd see if it worked first though as I've had my doubts if it was actually broken. Took me a couple of hours to download the software, firmware for the ecu and find the right driver for the usb-r323 adaptor but it did show up on tunerstudio. Bit of a google to remind myself how to set the ecu type and it works! The new ecu is better but its annoying that I probably didn't need it changed, it wasn't cheap and it didn't even run right when it came back with it anyway! Looking at building a dyno, there's not that much to it and its frustrating relying on other people. Some of which just make things worse. We're also moving house and I don't think they'll be any dyno places close.

-

Thats what I thought they were set at and was going to try a little less overlap. Will see how it goes at 110/110 then try it at 108/110

-

Runs good, typically my boost gauge doesnt work now so I'll sort that out before the next dyno run.

-

Dragged it down the shed this afternoon, fitted some split washers on the headers for now. Checked the cam timing and exhaust was spot on at 110 degrees, the intake was at 105 degrees though. I double checked everything and got the same results so I must have set it wrong last time. I remember going around in circles last time so I obviously confused myself! Left the exhaust cam alone and set the intake to 110 degrees, will get it on the dyno again and see how it goes. Needs a run out tomorrow first though.

-

Gsxr 750 WP wiring query

Danm54 replied to Spadge's topic in Water Cooled, V-Twins, Singles and 2-strokes

Some models were fitted with twin horns so I guess thats what the spare O/G and B/BL are for. The pink wire is connected on the RF9 and it retards the ignition in lower gears, its common to unplug it for more power in those gears. Guess it's just in the loom on a lot of models even though it doesn't do anything. -

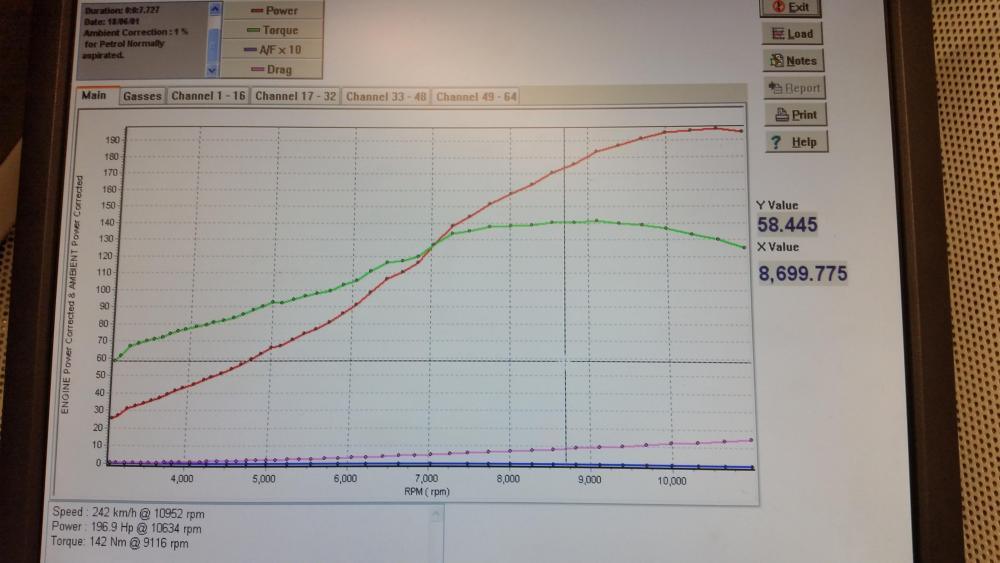

Been on the dyno today getting a base figure before I play with cam timing a little. Pretty much the same as it was on Dans dyno. Lost 2 header bolts again so I'm going to try and find some stainless locking tabs and use hex bolts. Going to alter the intake cam a degree or 2 and see if it helps, either more power or smoother running at lower rpm.

-

Nice idea, can see it being useful if you remove engines regularly and much better than the one that bolts to the cam chain tensioner.

-

I remember one that bolted in place of the cam chain tensioner. Think there were concerns of lifting the engine on 2 M8 bolts in cast ally but it seemed to work ok.

-

If there's a place to get your OSS related products scrutinised, it's here!

-

Inner 2 are close but outer 2 are different. Won't fit without cutting unfortunately.

-

Think it can go in either way but if its worn then it might seat one way but not the other. Could turn the fuel off every night to help but it won't solve the problem.

-

Still got the cv carb on it? Once mine started playing up no amount of rebuilds/cleans sorted it. Got a pumper carb in the end and never looked back.

-

Well as the turbo bike is kind of running I'd like to do some straightliners meets, 200mph would be nice but might take some building up to.

-

Ride to your local friendly garage and get them to take it off with an impact gun. Pinch it up and ride home.

-

RF9 swing arm is narrower than the slingy one, bit shorter as well but should go in with some top hat spacers.

-

Well it already reduces fuel to .6 with the ignition cut, I wouldn't do it without ignition cut. I don't see much point it firing fuel in if its not going to be ignited but I guess its better than too little fuel when it ignites. If I set the multiplier to 0 that would cut all fuel and I could set the ramp-out to 0 as well, don't want it bringing fuel back gradually. That should cut fuel and spark simultaneously for 60ms and bring them both back together.

-

It's been set to ignition cut so I assume it doesn't retard the ignition but it does reduce fuel. I could reduce the fuel even further as a total ignition cut wouldn't ignite any lean mixture.

-

Its the linkage triggered shifter, and yea mine is the one that bangs and shoots flames!

-

Ok, got the option of ignition cut or ignition retard Gear cut time is 60ms Fuel multiplier is 0.6 Ignition retard is 30 degrees Retard ramp-out rate is 30ms So I can change it to ignition retard Drop cut time in stages I guess to find the minimum it needs Fuel multi might as well stay the same? Ignition retard - I'm not sure if it pulls 30 degrees off the timing or sets it at 30. Will have to call Specialist Components to find out. I'd guess it pulls 30 degrees off the map though. Not sure how much ramp out it needs but I'll ask about that too.

-

Using a Specialist Components Typhoon ecu. Injectors are right before the head so as close as you can get to the valves. I'll check how long the ignition is cut for, I guess if its not long enough it won't shift. Will also check what other options I have.

-

The quick shifter on the turbo is currently set to ignition cut and works fine at low throttle openings with the usual pop and flame out the exhaust. But as I'm shifting at higher rpm and throttle opening I'm feeling the pulse out the air filter as well, its also one hell of a bang. I've read plenty of opinions on fuel cut and generally its considered ok as long as its a total fuel cut and not still injecting enough to cause a very lean condition. Ignition cut is also considered quite hard on the turbo/manifold and with the harshness that its exploding I'm worried about causing damage especially if I'm feeling it out the intake. I don't think I've got the option to pull timing but I'm not sure thats a safe way to go either. So whats the opinion in here? What are you using and how effective is it? Thanks

-

I know its watercooled but same kind of thing, used straight adaptors on the sump to an8 fittings. Adaptors to the standard oil cooler were a nice find as well.