Fredrik_Steen

Members-

Posts

308 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by Fredrik_Steen

-

What do you think was the root cause for the failed ringlands?

-

What was the failure and root cause?

-

I vote for leve them as they are and send it. If you have the ability lower the ignition 1-2 degrees at peak torque.

-

Best feeling when it finally runs and idle

-

Flex fuel with EFI, what CR to go?

Fredrik_Steen replied to IhmeJanneFIN's topic in Forced Induction

Since you use EFI i would say go for compression and if necessary drop the ignition timing some degrees when pushing high boost on pump fuel. -

Maxpeedingrods are excellent value for money and they will outperform what the gearbox can hold.

-

Works great, no issues at all

-

It might be cavitation due to not enough flow into the pump / some kind of restriction. When the pump cool off it works again for some time.

-

Are you loosing pressure after 5 minutes or what is the issue?

-

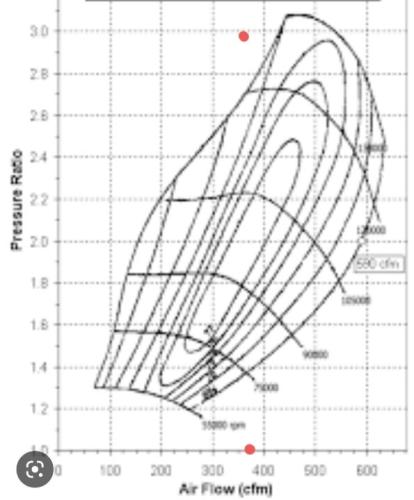

Yes i based my recommendation on this map ( I added two red dots). And a estimation that he will be pushing around 2 bar to get 360ish hp without intercooler. I think this turbo are more suited for a stronger/more tuned base engine

-

I'm guessing it's the maxspeeding brand you are looking at. It's cheap Looking at similar compressor maps I don't think it's the best choice out there for your application. If you still have stock b12 camshafts in the engine I think 150ish are a bit optimistic.

-

It's hard to say what a turbo are "good for" It depends on your engine combination. In your case I would calculate with a 120hp engine. At one bar it will produce 240hp. Two bar = 360hp if the exhaust back pressure are kept in check and the intercooler can support the heat. Roughly estimations, but gives you a idea when you check compressor maps

-

If you can afford it I would go ball bearing, journal's flow a lot of oil (that oil you want to keep in the crankshaft bearings) Learn how to read compressor maps, I like this channel They have several videos on the topic

-

It's not optimum. Like Gixer1460 said get slotted sprockets

-

Yes, a 2mm spacer will do about 6 degrees

-

I got mine locally here in Sweden by a steel company. The washers are minimum 45 HRC Dimensions was 10.4 x 20,4

-

I torque to 50-55 ft lbs lubed (depending on the feel in the handle) you can't use the oem washers Steel and copper. They are to soft and you will loose tension. Buy special hardened washers

-

What are your favourite myths on turbo or suzuki oilcooled engines?

-

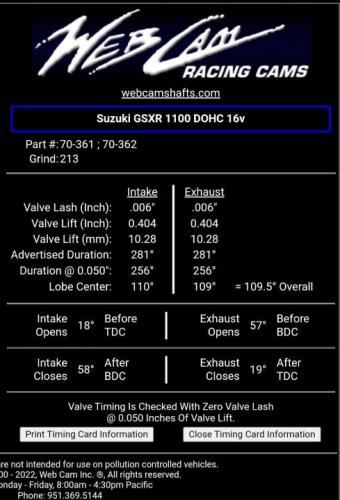

I'm more interested in low boost and big HP numbers. Efficiency and a good base engine I also agree that high lift and shorter duration are the way too go if the NA engine likes it. But I don't believe that the boost will go straight into the exhaust if you have a little more duration. The reason I have the specific camshafts are that they where on the shelf when I was going to buy and I didn't want to wait for other grinds to be manufactured. But they work great.

-

MTC advertise cr 10.0:1 for the pistons I use But the cylinder and head has been resurfaced two times so probably i got a little bit CR

-

What works NA also works with boost. There are plenty of test's out on Youtube on the topic. I run this camshafts that has a lot of duration with good results

-

Ring Gap, Stock Valve Springs/Valve Questions

Fredrik_Steen replied to rider384's topic in Forced Induction

Do you have the compressor map for your turbo to upload here? That ones i found on Google seems to only support about 1,8bar Think you will be looking at a water to air intercooler system for your setup. The rods you have are awesome -

Ring Gap, Stock Valve Springs/Valve Questions

Fredrik_Steen replied to rider384's topic in Forced Induction

Looking at the compressor map for the K04-015s you are on the edge. A decent work on cylinderhead would be nice so you don't need to push beyond 2bar. A lot and a lot of intercooling are a big must. ignition retard are your best friend to reach your goals. Don't push to mutch boost in the peak torque curve - be wise with your boost controller. You really don't want the rings to bottom up at any point Nice experiment you are running, keep us updated with progress later on -

1216 Build List + Very Basic Questions

Fredrik_Steen replied to rider384's topic in Forced Induction

I ordered my washers from Daniel Leander on facebook, he makes for Hayabusa and Bandits. APE doesn't make washers unfortunately.