-

Posts

32 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by Jmckechnie

-

Yessir, these ones are printed as such.

-

It’s 100%possible. I’ve jammed gsxr1000 Tb’s into the stock 750L boots… but going forward I’m going to try CF reinforced nylon 3d printed intakes. I have some mocked up for a 600can-o-tuna that will fit gsxr600 tb’s. in the picture- rubber boot is far left. Gen1 printed manifold in the middle. And first trial boot is on the right. I’ve got all 4 printed up and modified the spacing for perfect alignment with my new TB’s There are lots of great ways to convert your bike to FI!

-

yep, it sure is. A friend of mine built it, but couldn’t get the motor stuff sorted out. So with the help of the OSS crew and the infamous @Arttui was able to convert it to EFI with full spark control. She runs really good! Just need some dry salt flats to run it now

-

After hours of searching ( I apparently suck at finding the info I want) I ended up finding your swap and took some notes. I’m going to probably just swap in a full B6 front end, and press out the steering stem as suggested by @davecara Gotta try to give this old GS front end a 150mph+rated front tire!

-

Nice work !

-

Do you recall what you did to swap the b6 front end into the GS? I’ve got a few B6 front ends and I want to get this done on my ‘78gs1000

-

@latheboy more details on your 750 turbo! what kinda mods have you done, and what model 750 did you use? Turbo info? Injection info?

-

Mean looking ride @ApocWarrior

-

Thanks very much. None of it could have happened with out the resources I picked up from this site and a few selected individuals in particular

-

Heavy duty parts for short stroke 750?

Jmckechnie replied to IhmeJanneFIN's topic in Forced Induction

@IhmeJanneFIN glad to see another 750 turbo project on the go! There aren’t as many out there as the other bigger bikes. I’ll be following ya on this one. I’ve done a 750 turbo myself, but I used a 750L as my mule. I don’t know much about the short stroke 750’s, but there seems to be a lot out on the road still! In Canada at least.. I’ll be starting my second turbo bike project shortly- my platform will be a GSXf600. Target HP will be around 200. After discovering all the similarities the 600’s have with the long stroke 750’s, I can’t wait to see how the end result will work out! I have several longstroke 750 motors , and recently picked up 2 mostly complete gsx600F’s. I just need a place to work on them now -

‘90 750L EFI, Borgwarner snail 200hp even at the rear wheel @1bar. Extremely streetable- so much so that I’ve even built a seat for my son to come along for a ride ( it hides under the rear seat cowling). It’s also fast enough to push 180-190 at the bonneville salt flats on the intermediate course.

- 108 replies

-

- 13

-

-

This engine is slightly larger then stock, I think something like 1080 or 1090cc. I can’t remember exactly what bore is, probably 1mm over stock.

- 25 replies

-

- 1

-

-

Update: Had the head and cylinders inspected for flatness at a local machine shop- he took a tiny bit of material off the head to clean it up and otherwise said the cylinders were in great shape As for gaskets I went with an MLS OEM gasket- didn’t have a large enough opening for the o-ring groove for the cam chain tunnel, and had no o-rings to seal the studs up to the head. regardless, the install went smooth and guess what- not a drop of oil has passed by with hours of thrashing on the bike in its street tuning chassis. It’s now home back in the LSR chassis, ready to race when ever the boarders are open. Thanks fellas!

- 25 replies

-

- 2

-

-

@mikeydthank you, but Suzuki takes the credit for building a solid motor! The motor is totally stock aside from heavy duty custom turbo pistons from WEISCO. If i I have any kind of aerodynamic aid, it will most definitely put me into another class. For now I chose to race in the open class to keep my build simple. A fellow I was privileged to meet on the salt and fellow Canadian ( Tom Mellor, google ‘Tom Mellor triumph’) has a VERY impressive aerodynamic fairing that was home Built and had propelled him into the 200mph club several times with naturally aspirated motors.. one year he rode his bike in 2 classes, one with and one with out the fairing. That fairing gave him a 40-50 mph speed difference. I think typical gains might be in the 20mph range with proper aero. The engine he was using when I met him was in the 1000cc class, and made a whopping 110-115hp, and his shake down run came in at 192mph!!! One day I’ll take a chapter out of his book, and I’ll build a similar fairing.

-

A reply I received from Dynoman when I emailed their tech support yesterday: ”Hello Jason, We have been building the GS1000 motors for the street and track since 1978 when they first came out and can truthfully tell you that they are one of the best motors that Suzuki ever made. That said there are a few guidelines that that you must follow with any engine for it to be reliable. We address a few below: Copper gaskets are very strong and dissipate heat quickly, but are not as good at controlling oil as other gaskets. They do need to be annealed to make them softer for a better seal, and there are many different sealers available that work with them as well. They are very good for drag bikes and other race applications, however they are not our first choice for the street. We can custom make an MLS gasket for you up to 76mm bore. The price would be $83 and take about 2 weeks production time. You also have other problems that need to be addressed as well. We never run 12:1 CR with stock cams, as they require more lift and duration to work properly. With the stock cams your motor will make excessive heat and not make good power in the higher RPM range. You will also have excessively high static compression that can damage your motor very quickly. Please tell us your bore size and pistons manufacturer, what you are running for carbs the exhaust that you are running, and the type of riding that you like to do and we will be happy to go over your options. We would not recommend that you run the motor until it is built correctly to avoid damage. Just let us know if you would like to order the MLS gasket and we will be happy to send you a PayPal invoice that you can pay with any major credit card. If you have other questions please feel free to email us and we will get back to you ASAP. Have a great weekend!” anyone want to chime in on these points? we ran the 1000 with stock cams, and to be honest we didn’t notice anything abnormal ? But we also weren’t monitoring cylinder head temp or engine temp much at all

- 25 replies

-

- 3

-

-

I suppose that might work like a hot damn ! Where did you source your gasket from?

- 25 replies

-

@Reinhoudjust to be clear, that’s a composite cosmetic head gasket? 17psi boost on a GS1000!!?? What kinda rwhp do you see with that? I’m interested in the mods you’ve made to your motor to cope with that power-is there any where I can read up on your build?

- 25 replies

-

@RickLeeGenerally speaking, this will be a race only bike. For now to get a proper tune belt for the fuel injection, and to set my ignition tables etc. it will be installed in my GS 750 Trac generally speaking, this will be a race only bike. For now to get a proper tune for the fuel injection, and to set my ignition tables etc. it will be installed in my GS 750 chassis And will be my ‘daily driver’ until its tune is perfected

- 25 replies

-

@Gixer1460 1. Are you referring to the o-rings that are typically used around the combustion chamber to seal cylinder pressure? Or are there supposed to be o-rings for the oil ( or coolant ) passages when applicable? 2. Annealing the copper- is there a tried/tested/unfailing method you could refer me to so I can ensure it’s done correctly? 3. I remember him using some kind of ‘glue’ on the gasket after the first attempt at installing a copper gasket. It improved the situation but not by much. @RickLeethanks for the suggestion! The owner of the bike has told me that WEISCO suggested using copper head gaskets with their 12:1 comp piston kits. Can you verify the composite gasket will hold under such conditions? I’ve been doing some research on gaskets and when to use them- according to HP Academy they don't recommend using composite gaskets for compression ratios above 11:1, and according to them 11:1 is Pushing your luck. I’ve got no experience whatsoever with head gasket selection- I’ve always just used what comes with them, and never altered a compression ratio so significantly that a new gasket was required.

- 25 replies

-

- 1

-

-

I hear ya on that Arttu! Anyone have any idea where to source some MLS gaskets ? The engine has an approximate bore of 73mm I think, it’s slightly larger then stock.

- 25 replies

-

I have a problem with a high compression GS1000 engine- the man who owns the bike was told to run copper head gaskets in his 12:1 compression GS1000 but the copper gasket is leaking oil in a bad way. There are no o-rings in between the head/jugs, just the gasket. I’d like to switch to MLS or find a way to stop this copper one from leaking. Any suggestions? I’ve got no experience with copper head gaskets whatsoever

- 25 replies

-

@GSX1100dreamn thanks!! Thats valuable info, much appreciated. Do you know the throttlebody ID for the 1250F? I’m thinking the 650f would be best for my application. I’ve already learned the tribulations of tuning a bike with monster throttle bodies , I’ll avoid that in the future if possible haha.

-

Hey Wee Man, I guess I’ve been visiting this site and lurking in the dark long enough to feel like I’m already part of the crew but still didn’t learn enough to RTFR.. oops. Thanks for the reality check.

-

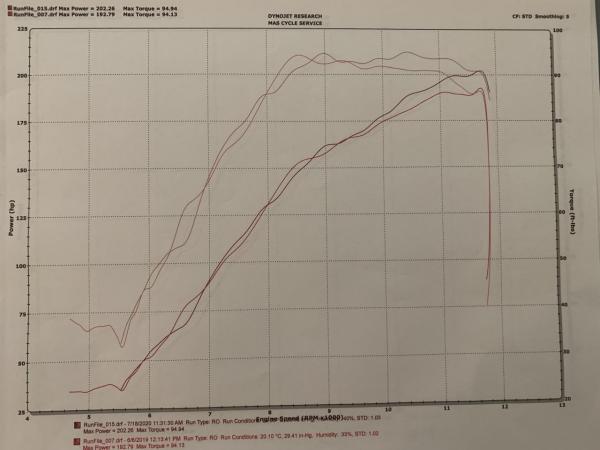

I have a 1990 GSXR 750L, currently set to run 14.7lbs Boost and lays a solid 200hp at the wheel. I managed to set a 750-M-BF record in Utah last summer with a 180mph qualifying run and 184 mph backup run on the intermediate 5mile course. Next time I’ll try for the long course and see what it can REALLY do! Engine Management System - Megasquirt 2, V3.0 board operating MS2extra 3.4.2. I have a CANEGT module with 4 closed tip probes for 1-4cyl, 2 open tip probes mounted in special adapters to read pre and post oil cooler temps, and one mounted right after the turbo to show me turbo outlet temp readings. I’ve also got a turbo oil feed pressure sensor, a main oil gallery pressure sensor, and a fuel pressure sensor- I can only read one at a time ( out of analog inputs ). I’m using Speed density engine control and batch injection. Ignition system: stock VR sensor reading cranks speed via 24-2 trigger-wheel made by Arttu, output controlled by MS2 FET drivers —->triggering a Mitsubishi J702T ignitor(from a Mazda miata I believe), and I’ve been using an IGN4 wasted spark coil with regular ole wires and plugs, nothing fancy. Oh, and CR10 spark plugs with a slightly reduced gap. Throttle bodies: k7/8 tb’s spaced in the middle and jammed in to the stock boots, with stock injectors. I’m using a staged injection setup- once I reach a high enough duty cycle on my primaries I transition to 50/50 between primaries and secondaries. Duty cycle at current power level is about 65% Injector sizes: Primary and secondary are 225cc I believe. Std Coils or Pencil stick coils (type / part number / model) : IGN-4 wasted spark Fuel pressure at pump: walbro pump but I can’t remember what it flows (255 I think)- I do remember that it had 30% excess fuel flow at a flow rate to give enough fuel for 300hp. Aeromotive FPR referencing port vacuum/boost. I have an MS3x ready to plop in there with a BUNCH of additional sensors and hope to have this baby fine tuned and ready to race on the salt again in 2021.. Here are 2 dyno runs almost a year apart. They’re both in red ( sorry ) but the light red was last 2019, and darker red was a few months ago. Since my first trip I’ve tried to flatten that torque up top, and my little tweaks worked, but boost control is not my strong point so there are some fluctuations I was a happy camper after I tortured it in bonneville.. 9 runs in total. My last 2 runs were wot for around 50 seconds! Thanks to a solid tuning platform, my AFR was solid at 11.5-11.7, and with all the other information I was able to collect I could run with confidence and focus on staying straight and upright. I owe a lot of what I was able to accomplish to a lot of you guys- by posting and sharing experiences online in places like this, I could learn and teach myself what to do ( and what not to do hahah). Thanks fellas Oldskoolsuzukis kicks ass!

- 106 replies

-

- 15

-

-

Has anyone found the answer to this? I’ve been long for some info regarding the spacing as well- I want to TURBO/EFI a 600katana