-

Posts

5,415 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Posts posted by Gixer1460

-

-

Mostly anything is possible - just down to time, money and tools to achieve! The issues likely with your proposal is 1. Base gasket joint / mating surfaces between cases and cylinder block, 2. Area around cam chain tunnel in block and cylinders and 3. GSX Cylinder sleeve OD dim fitting into GS case holes. Obvs GSX head and cylinders will match but you will have to make sure GS piston pin small end size matches GSX pistons proposed - GSX early was 18mm / GSX late was 20mm and I believe GS were 18mm (but don't quote me!) Cam chain slippers may be a mish mash to suit!

-

11 hours ago, demt said:

Erm where is the igniter located as I need to check it

You seem to be new to the conversation? Is this the same bike / what bike are you referring to? Look at the picture further up - it shows the Ignition box (most look similar) #29 - usually found somewhere near the battery / under seat or side panels. What are you planning to check as generally they work or they don't!

-

5 minutes ago, wraith said:

Would that work on a 1127 or just the b12 ?

Probably just the B12 due to the piss poor CR!

I'm wary about using 4 or 5 deg advancers - not a thing that works with higher CR's nor piss weak fuel and can make starting a chore if battery is a bit dickie!

-

2

2

-

-

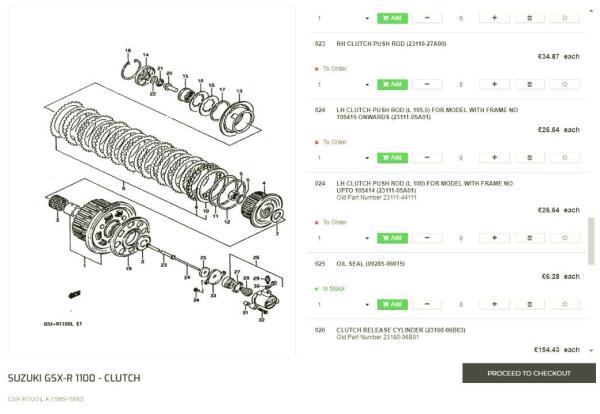

Interesting ! Robinson's list two lengths - an early at 100.0 and a later at 105.0 ! The earlier has a superseded part # but its revised to the later one ! ! ! Guess its check engine # time!

CMS on the other hand only quote one part # 23111- 05A01 but no length given but compatible with 1100 K, L, M & N - so, all the Slingshots.

-

1

1

-

-

Has it worked ok before? They are notorious for not bleeding easily although the few i've done came good after a while!

If it has worked previously, then the rod length is correct - if parts (ie. cover / clutch) have been changed then all bets are off . . . . unfortunately!

-

9 hours ago, Duckndive said:

Did Kev break cranks Ian @Gixer1460?

Never - not one (or at least he never told me LOL) Seriously though, Kevin's was a baby motor - only 1371cc. I believe Brock's were punched out to 1500cc maybe more & so were using billet cranks by necessity. Kevin's were reworked std Suzuki and as both Ken Cooper and Big CC had fingers in his engine at various times - who knows who did the crank work. Never had a spare though unlike the ProMod !

-

1

1

-

-

If you want to save on the cost of junking fresh oil - diesel will work for flushing - at least you can then run that through a car or truck - Win / Win!

-

New or old, if a battery is goosed - its goosed! I managed to kill a brand new battery between work and home approx 30 miles - mainly motorway and lights on, to the point that it was misfiring 1 or 2 miles from home - a duff regulator / rectifier will do that for you! I'd say the battery is deffo suspect as they don't like deep cycling, and maybe the genny as Arttu says the AC output is low!

-

30 minutes ago, TLRS said:

Where would you prefer to have it..?

I guess you don't get sarcasm

-

1

1

-

-

No, it's a Blandit ! RTFR's

-

1

1

-

-

I would guess the pin-out pattern will be similar / follow the GSXR (as the obvious competition variant) but without the tacho output from the RHS plug ?

-

On 2/26/2024 at 8:46 AM, johnr said:

Is it that o ring that's leaking? Plenty of oil leaks on heads are due to the o rings on the centre cylinders head nuts.

I think you are confusing this GS head with a GSX one - all head nuts on GS head are external, so just need steel / copper washers.

-

My Brain hurts !

-

that explains a bit ! so if you used gsx pistons in a gsxr you should get a similar low CR?

-

MTC used to be the 'go to' in GSX draw through installs as advertised @ sub 8:1 CR - it's the same piston used in turbo GSXR's but with shorter stroke gives 10:1 CR! Wasn't going to say anything as you wanted lower!

-

1

1

-

-

Now I'm blushing !

-

1 hour ago, DAZ said:

Is that like a joe90 clutch for big boys ? I assume it's adjustable for biting point (rpm) maybe by weights or distance between different internal parts ?

You got it - Half the skill in drag racing is in the clutch tuning! Launching 500hp on a two step at WOT and not blowing the tyre away takes some clever shit!

-

1

1

-

-

3 hours ago, Duckndive said:

Since that interview It now has a full billet motor $$$$$$$$$$$

Not exactly a budget build anyway! I wonder which bit is still / remains Suzuki produced ?

-

1

1

-

-

Slider clutch! Or twist and go for drag racing!

-

1

1

-

-

1 hour ago, R1guy said:

Chaps, let’s not beat around the bush- why not fit a regular oil boiler turbo’d motor.

cos shaftie frames don't use 'normal' swing arms!

-

Electrics that old are going to try most peoples 'Grey Matter' ! When you said 'replaced the brushes' my immediate thought was Generator / Dynamo - surely not but looked up the parts fiche on Robinsons and its described as an alternator except its backwards to how we normally see them, in that the magnet spins via crankshaft whilst the field coils are stationary! The brushes are doing what - i'm not sure !

Do you have a workshop manual Suzuki or Haynes ? ? ? That should have a reasonable explanation and troubleshooting section. Its usually the regulator / rectifier that goes bad, either over charging or not charging at all. They are all solid state and un-repairable (by most people!) and usually have to be replaced with something else - usually from *onda or ^^hama as Suzuki charging electrics from that era suck big time! Some colour photos of rotor and plate assembly could provide info what bits to test and what to expect, as this is likely as much a mystery to us as it is you!

-

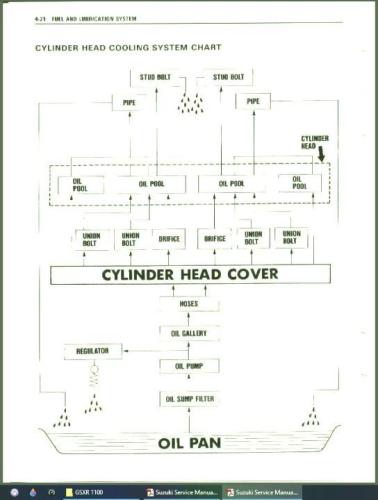

Yes, but the point is the filtered oil is delivered, at pressure, to the bearings whilst the un-filtered oil merely 'sloshes' around the head then drains back to the sump. I have no axe to grind, one way or the other and I do have my cooling circuit connected to the cam feed circuit without issues so far, but I've yet to see empirical evidence of cam bearing failure due - solely - to this combination, but I guess it is possible. Even if the bearing HP feed pressure was 'diluted down' to cooling circuit pressure (30+psi at a guess but with greater volume) that is still more than adequate to prevent metal 2 metal contact - Aircooled GSX's survive at considerably lower pressures for cosmic mileages!

It is a good reason to keep on top of oil and filter changes though!

-

1

1

-

-

56 minutes ago, Duckndive said:

Just read that again on PC

Where does the "unfiltered oil" come from then

and how does it remain that way

and how does it remain that way

Unfortunately Clive, on this occasion he's right! See attached Cooling Oil Circuits diagram from the workshop manual. Cooling oil doesn't get filtered - bizarre I know but thats the way Suzuki designed it!

-

3

3

-

-

Aged battery? I'm guessing testing outside cylinder with 'down on power' battery also being pulled down with the starter motor?

At least you are getting sparks - its when you don't, that real diagnosis starts!

GS1000 block with GSX1100 cylinders and head

in Air Cooled

Posted

Normally just use cam gears that match the crank - GS bottom - GS cam gears. I've used gsx gears in a gsxr head on a efe bottom end. I thought Suzuki used same stud pattern all through GS, GSX & GSXR ranges.