-

Posts

73 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by Romaz750R

-

HI! Sorry for answering late... Marry Chistmas and Happy New Year! Dont khow the strenge of spring, just use for measuring peaces of broken spring, and pick something same. Still have "very very slow" leakage, but im OK with that

-

Frame number etched, not stamped. No VIN plate query

Romaz750R replied to Julianwinters's topic in Oil Cooled

I have no VIN plate too, because my GSXR is JDM. -

Hi all! I think much of us faced this problem... Can you advise so methods of solving this damage? Cutting off part of pipe, or trying to unscrew and straighten with heating?

-

Amazing bike!!!

-

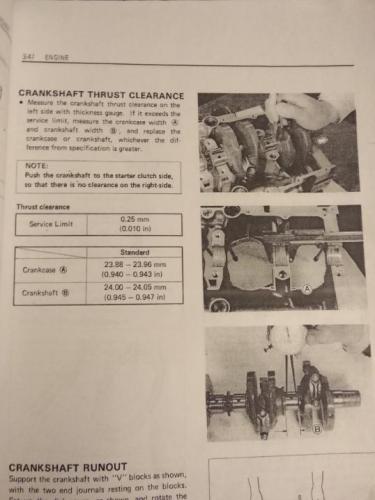

I probably got it. If servise limit of upper case clearance is OK, so its OK. If servise limit is exceeds, so i shouid choose thrust bearings for lower case.... I think so.

-

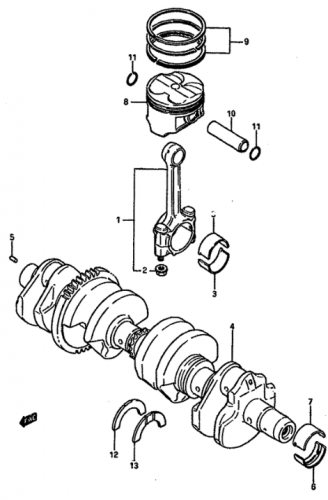

Upper part of crankcase dont have 1-2 mm gap. Its about 0.15 mm.. But also lower par of crankase have them - 1.5-2 mm. I understand that they should be there, maybe tell me how to choose them? And maybe you know the thickness of these plate bearings? Maybe some thrust bearing selection table?

-

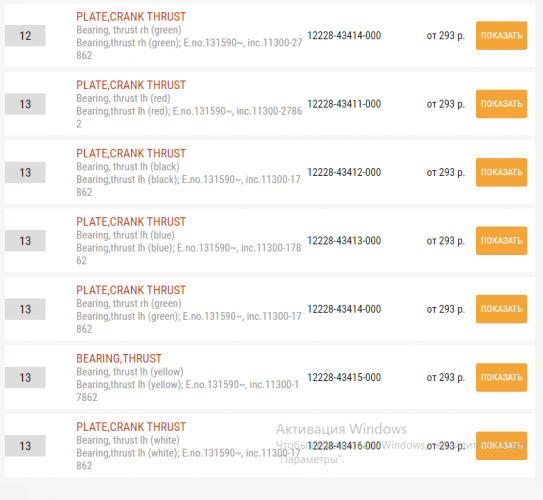

Good evening all! Mates, have one question about plate thrusts for crankshaft. Making some big order for engine overhauling, and trying not to forget any parts. So, question is - do i need this plate thrusts, if they were not there initially? Crankshaft thrust clearance is OK. I doubt it, because in some manual (I don't remember which one) I read "... if they were installed initially ...". And also they illustrated on partlist (pos.12, 13). GSXR 750 1986. Thank you in advance!!!

-

Please tell me, if i have code "A" on crankcase, which indicates size 35,000-35,008. so when i will be choosing bearing size, which number should I take into account? 35,000 or 35,008 or average between them?

-

Thanks!!! Of course! This conrods (all 4) are already were there, before i started overhauling. I have drove about 2000 km on this conrods/crankshaft. This is a puzzle that the previous owner left me)) So, will do my best!

-

Glad to have at least this

-

-

I'm trying to figure out if these conrods can be kept. Because, just looking at the picture, they look like from 90. And if the crankshaft for 86 and 90 is the same, then it means that i can install these?

-

Yes, i measured 18/34. 90s 750 engines are long or short stroke? Could it be, that this conrods from 90/750?

-

https://www.megazip.ru/zapchasti-dlya-motocyklov/suzuki/gsx-r750-2301/gsx-r750-13989/gsx-r750l-j-k-l-l-768012/kolenchatyy-val-porsheni-13342943 They look like this (90 750)

-

Good evening all! Have some situation, while overhauling engine... Need to check oil clearance on piston rods bearings. Noticed, that rods should be with nuts, bu i have rods with bolts. Do somebody know, is that rods with bolts from 90' gsxr? Or they could meet on early models? And main question, whats the assembly tightening torque? And initial and final tightening torque for checking oil clearance? Also have some scratches on crankshaft. Must have grinded some bolt or nut on previous engine... is that ok or better make it balancing? Thank you in advance

-

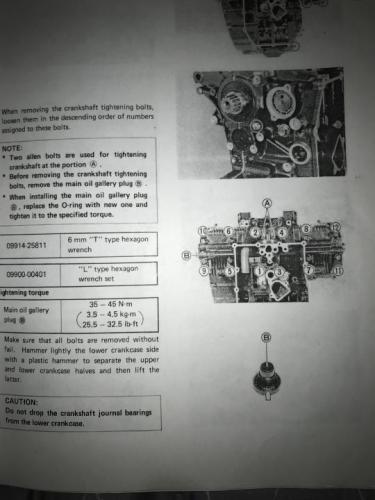

yes, but I couldn't get the wrench in any way due to bolt 9...

-

-

You mean №9?

-

Good evening all! First time overhauling engine on my 86 750. And of course a lot of questions arise during disassembley... manual says that before removing the crankshaft tightening bolts, need to remove oil gallery bolt. In my situation I have stripped hex in this bolt and have no instruments to remove it right now. So, the question is, is it correct to remove oil plug after separating crankcase? Go easy on me first time go so far into engine

-

-

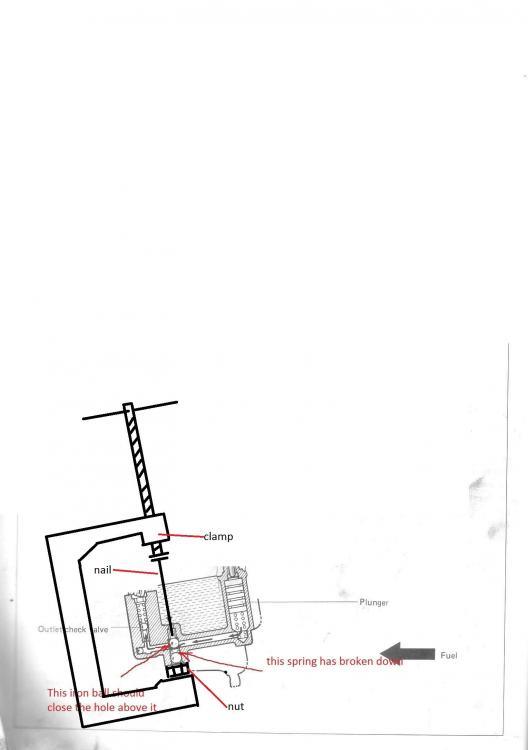

Yes, exactly! As i said, get nail, cut it straight, and push (as i showed on the picture) slowly not to break float bowl!. Still all right, no leaks!

-

I think thats fine!) I have a "spring shop" near

-

I bought a similar one. There is no in catalog. It was looked like spring of plunger (accelerator pump), but a little shorter.

-

Yes, it was easy enought. I used clamp and nail (you should cut off the sharp edge, becouse nail should push on the centre of upper ball). And i put the nut between clamp and lower ball (еру lower ball will go inside the nut). Press out slowly so as not to damage the float chamber. it will be also good to drop a little oil on the lower ball. Replace the spring, and press the ball back (dont forget the order: upper ball - spring -lower ball). The ball is tight enought and there is no leaks. Oldschool "charm" is good, but better when oil and petrol inside))