Tombola

Members-

Posts

156 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Everything posted by Tombola

-

If you have a member name or link to the thread would be much appreciated? I’ve had a google of using bandit 1200 bottom end with 1100 top end.

-

How different is the bandit bottom end to the gsx1100f? I ask because I have a bored set of barrels, low comp Mtc pistons, rods, and turbo I was saving for a 7/11 project.

-

Cylinder 2+4 have this in the both bores. Feels completely smooth, but obviously corrosion. The bike had been stood outside for a while, could also be condensation from not running the bike Thanks for all your help guys I’ll have to weigh up what to do with it I really didn’t want another project.

-

Done another compression test, 110 ish psi across all 4 clyinders, 1+4 being around 115psi. Engine was ran up to temperature this time. I also borrowed a leakage tester from our garage. I’ve followed the instructions and apparently leakage is low between 25-30% 4 clyinders. it is a sealey leakage kit so whether it’s any good?

-

I will tony I have a decent pressure gauge, just need a reducer to get to the 1/8” bsp of the tester body. It made good compression with oil in the bores which is unfortunate. But if it’s under reading that could be OK

-

Although that would be lovely… it’s a W reg half faired in maroon Can anyone advise on a cost effective repair for a all round hack?

-

I done a compression check on my 1200 blandit, WOT I’m getting 110psi ish across all 4 cylinders. Its a W reg and 30k on the clock, Mileage backed up by the mots. few cc’s of oil picks up compression to 150psi. It’s the cylinders right? Oil like that can’t help the valves seal? bike wasn’t screaming hot. it answers the question why it’s always been a pig, I just want some input in case I’m missing something Bike has always been rough cold, spitting back, rough coming on the revs, once warm it’s OK ish. Carbs have been ultrasonically cleaned by Jim at super bike surgery, valves clearances done and carbs are balanced. standard zorst, air filter, and new plugs thznks tom

-

It’s not a bad shout, but I would like to keep the vac petcock, because I’m awful at remembering to turn it off

-

Can anyone recommend a rebuild kit for a 00 bandit fuel tap? Fowler’s part list only do a complete tap?? But as you can see from the picture i just need that seal but I assume it’s a complete part with diaphragm. Are they all the same? I see all balls make a k1 upwards edition.

-

Ok... why are people so against the helical cut gears? I’ll add this was in relation to the F lumps reading up on it (some of which comes up from posts on here) I’ve heard of clutch’s coming through the side of the case etc but then this is the internet... id rather not have to buy a crank, clutch basket if mine is fine to use Thanks

-

I’m referring to crank and clutch should of put this in oil cooled sorry admin!

-

I have had a google.. I would like to change the gsx1100f engine i have to straight cut gears out of the gsxr. Can someone talk me through what I’ll need to change? ive had my F cases vapour blasted for paint, then I started reading about the side loads with helical gears and big power. I’d rather not buy another engine if that’s the case. thanks!

-

Italianeze Technoloy

Tombola replied to yantosh's topic in Water Cooled, V-Twins, Singles and 2-strokes

Fair enough, I’ll stop being nosey. All them solenoids had me intrigued -

Ha I was just about to update this.. I can’t help you with your problems, accept check check valve clearances, plugs, compression, any air leaks Right I’ve gone and adjusted all valve clearances, 0.2 exhaust and 0.15 inlet. Started up, and I THINK it’s cured!! I think my vision got narrowed in on them carbs, because of the parts I found missing but you live and learn! I can highly recommend the SMC24 from squealy made the job a doddle!

-

Italianeze Technoloy

Tombola replied to yantosh's topic in Water Cooled, V-Twins, Singles and 2-strokes

Nice! Next question... what’s it for -

Italianeze Technoloy

Tombola replied to yantosh's topic in Water Cooled, V-Twins, Singles and 2-strokes

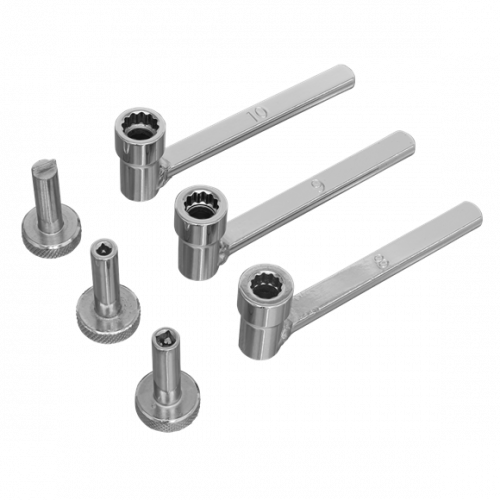

Just went through this build, incredible work! so much bespoke cnc can you put me out of my misery and tell me what this is please -

As far as I can make out they are kosher.. apart from these brass parts from Eblag!! checking the valve clearances and the inlet are pretty nipped up I can’t get a .1 under but can get a .05 feeler under...

-

That’s interesting, it was a keyster kit I had.

-

Nope, when you roll the throttle on it’ll spit between 3-4K get to 5k then the revs will die back to 3k then rev out! Speaking to the selling he’s refunded most of my money for the kit. I’m going to have to take it to someone with more experience, but it’s so annoying having an issue you can’t repair no matter how many times I’ve taken those carbs on and off checked double checked etc...

-

Thats lean right? @MeanBean49 @Gixer1460

-

I didn't think it would because moving the needle didn't make a difference but I will replace them. When you say link pipe you are referring to the exhaust right?

-

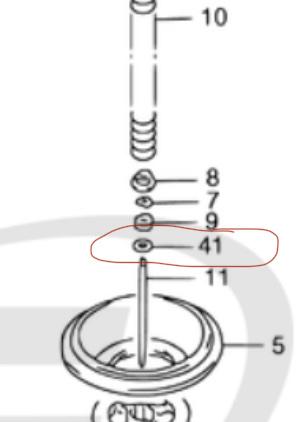

I’m clutching at straws because I took it the next needle clip down anyway. Someone take a look at this photo of the needle assembly, theres a washer between the slide and needle bushy bit. I don’t have those washers... I know someone’s been at these carbs before as originally one carb had that top hat bit that applies spring pressure onto the needle missing! if someone has a set of bst36ss handy to do a quick measurement on how thick that washer is I really would appreciate it.

-

It’s not even rideable chap, it was problematic before but rideable used to surge when coming on the power, bit of research pointed to the emulsion tubes. These have all been changed along with everything else in the kit. Ill try and upload a video later Ron. there’s a few threads already started on carb issues, none of them have came back and confirmed if they fixed/solved it though... I promise I will come back and tell everyone

-

It’s hard to see in a picture but when you have them in your hand you can see that the taper is deformed, almost like the metal is too soft or the taper has been cut right. I’m not sure what seat into I assume it’s just a hole?