-

Posts

1,155 -

Joined

-

Last visited

Content Type

Profiles

Forums

Events

Posts posted by Reinhoud

-

-

33 minutes ago, peter1127 said:

I don’t think the speed in which it spools up results in problems. Afaik detonation when turbocharged occurs around peak torque, or at prolonged high rpm when everything gets ff hot. Both have nothing to do with spooling up.

I can imagine a poorly chosen turbo heats up air more which doesn’t help.efi and carbs both are fine as long as afr is correct. You can run into fuel starvation with carbs when you turn down the pressure too much to prevent flooding. Then again there are multiple ways to f up efi too :-)

I had a TD04 on my GS, kicked in nicely, had a bit of detonation. The VF20 I had had quite a bit of detonation, spooled up real quick! The TD05 I had had hardly had any detonation, spooled up sort of slow, but still kicked in. Got a VF23 now, doesn't kick in, spools up even slower then the TD05, although it's smaller, no detonation at all.

So, according to my experience, the slower the turbo spools up, the less detonation.

Also, apparently, the slower the turbo spools up (or kicks in at higher RPM), the less change con rods fail...

No expert, but I do have some experience with different set ups

-

On 3/29/2024 at 9:38 PM, peter1127 said:

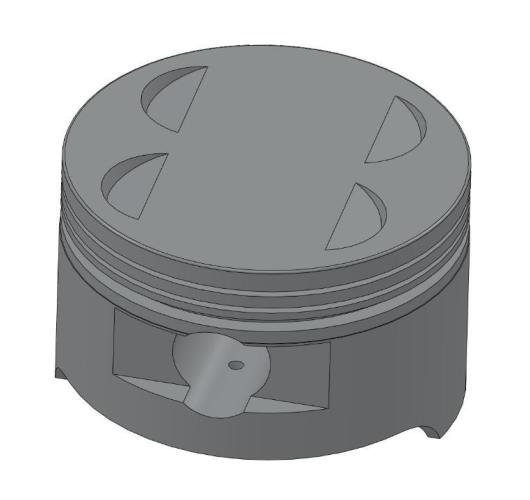

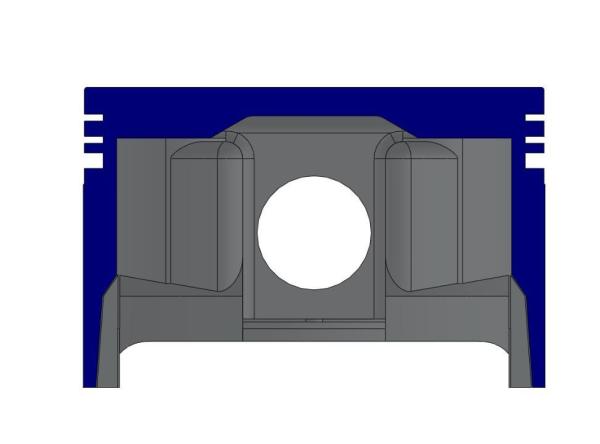

Got the MTC 81mm 10:1 pistons. They are much beefier around the wristpin area. They are now boring and honing the cylinder block. Before I mentiioned I want the CR to be 8:1 - 8.5:1. Reading a bit more in various places I think its a bit too low for a road bike. 9:1 should give faster spoolup and better low end while it should enable 15psi on 98 octane resulting in around 270hp. (input welcome)

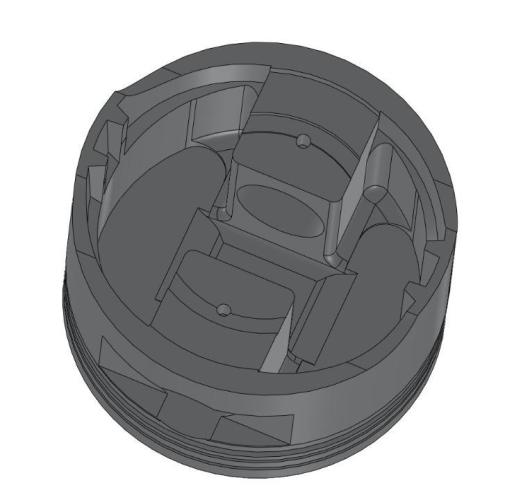

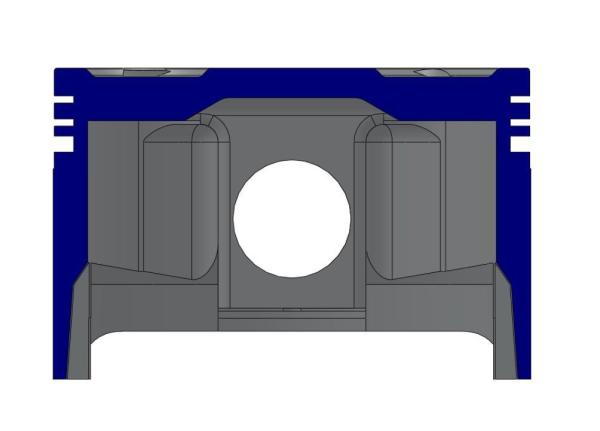

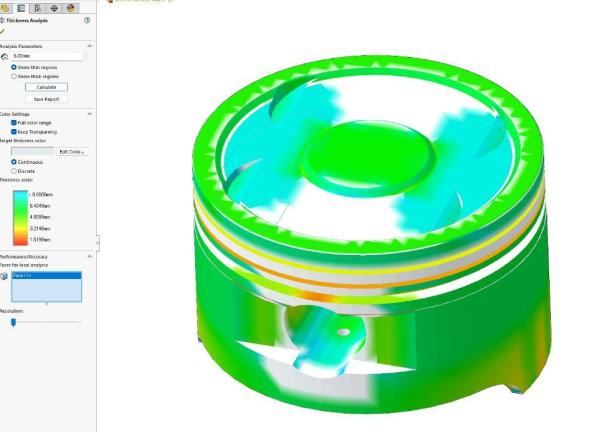

Played in CAD with the pistons to see what could be done to lower the CR while maintaining squish. Around 4cc should be cut from the piston to achieve 9:1. Thing is, in the middle of the piston is a relatively thin area of 5mm which I think I should leave alone. A bit surprised that turbo/nitrous pistons have a thin area in the middle. Maybe because they mainly make high compression pistons from this casting? The rest of the piston is 9mm so I could reduce that by milling out a ring 1.5mm deep. Of course I'm first going to verify deck height and actual compression volume before ruining new pistons

Does that make sense, or does that f@ck up combustion in such way that it would be better to add a spacerplate and accept the larger squish?

unmodified MTC 81mm

Unmodified MTC 81mm

Bottom of MTC piston

Modified MTC

Modified 81mm MTC

Modified 81mm MTC thickness check

Not much experience;

What I noticed, the sort of turbo, as in, how fast it spools up, determines a lot if you get detonation or not.

AFAIK, there are a few guys here who have EFI who have no problems with detonation.

In hindside, I'm not sure that they don't have problems with detonation because of the EFI, or the sort of turbo..

-

15 hours ago, badger said:

Same turbo and does similar. Mine starts boost about 3500rpm, stays at about 10psi for ages but doesn't hit 1 bar until 8-9k. (14psi spring and I do get boost creep sometimes). I'm sure it used to build boost a lot quicker but I'm questioning that.

To those that know, would a softer, say 6psi spring and a digital boost controller alter that characteristic letting the controller cap the limit higher, i.e 15psi etc?

If you ever use a boost controler, use one with a ball and spring. These build up boost way faster. Bleed valves just bleed/leak, this takes longer to actuate the waste gate.

Ball spring controllers you recognise on nipples on the bottom, and one 90 degrees on the side

-

1

1

-

-

14 hours ago, badger said:

Same turbo and does similar. Mine starts boost about 3500rpm, stays at about 10psi for ages but doesn't hit 1 bar until 8-9k. (14psi spring and I do get boost creep sometimes). I'm sure it used to build boost a lot quicker but I'm questioning that.

To those that know, would a softer, say 6psi spring and a digital boost controller alter that characteristic letting the controller cap the limit higher, i.e 15psi etc?

Interesting... The more revs, the more power, but it never gets really exciting.. With the TD04 it starting to lift the front wheel in 4th gear at 110km/h, now it needs to do 160km/h before it does lift the front wheel, just to give an idea.

It looks like there's a boost leak, but there isn't, I think..

-

1

1

-

-

I just remembered that about 12 years ago Dynoman send me accidently a GSX gasket set imnstead of a GS gasket set, I also have a GS headgasket laying around..

The dowel pins, and the 4 studs between cylinder 1 and 2 and cylinder 3 and 4 are the same with the GSX and GS. The 4 outer studes, and the 4 studs beside the cam tunnel are different.

A GSX cylinder block will not fit on a GS crankcase.

-

Not sure if helpful;

Years ago I had problems with my GS1000, ran like crap, couldn't figure out what was wrong with it.

I always buy parts from a Suzuki dealer, Suzuki says you should use Denso or NGK sparkplugs, at that moment I had Denso sparkplugs in it. Can't remember why, but I bought new sparkplugs, NGK this time, all problems gone...

So, before you start replacing the expensive stuff, are your sparkplugs alright? A good spark outside the cylinder doesn't mean it's ok, I've learnt..

-

Do the gsx cylinder block fit over the gs studs?

-

3 hours ago, Arttu said:

I think your boost drop is actually boost spike

It's probably caused by the wastegate actuator in combination with your boost regulator. Maybe the actuator has more volume so when the gate starts to open it needs more air through the regulator before the gate is properly open and that causes delay. And if the actuator has softer spring you need to turn the regulator more close which slows down the reaction too. You can test it without the regulator and see how it works then.

It's probably caused by the wastegate actuator in combination with your boost regulator. Maybe the actuator has more volume so when the gate starts to open it needs more air through the regulator before the gate is properly open and that causes delay. And if the actuator has softer spring you need to turn the regulator more close which slows down the reaction too. You can test it without the regulator and see how it works then.

Gradual boost building might be just a feature of the turbo but that's hard to say without detailed data. One explanation could be that the VF23 has bigger A/R turbine side. I think my VF34 behaves more or less same way. It starts to build little boost pretty early, slightly above 3000rpm. But it needs quite much more rpms to reach full boost, over 5000rpm for 1 bar. So there isn't any violent kick at any point, it just pushes harder and harder as the revs rise.

Aha, I didn't look at it like that.. It does look like that with this turbo the last 3 psi do way more as with the TD04

With no boost regulator it's the same. So it's the nature of the beast then, mine does the same as what you discribe.

I thought I might have a little leak somewhere in the exhaust or the valve of the wastegate.

Problem solved then

I thought that because TD05 is bigger the VF should spool up quicker as the TD.

What I did notice, with the VF I don't have detonation anymore.

Thanks

-

Hi all,

I had a TD04 on my bike (GS1000), put a VF23 on it, have the same boost regulator with a ball and a spring.

When I give it to her now, the boost gauge goes to 15 psi, and after about a second it drops to about 11/12 psi.

It never did that with the TD04. I know I can solve it by raising the boost a bit, but might there be something wrong?

I also think the VF23 spools up a bit slow, the TD04 was more fun. I had a TD05 on it when I did put a turbo on it, it was a bit laggy, but on boost it went very well!!

The VF23 comes in very gradually, doesn't really kick in, the more revs the harder it goes, but never really exciting, the TD05 did get exciting and that's supposed to be a bigger turbo.

For some reason I think there's something wrong. I disconnected the wastegate, it still spools up the same way, makes a fair amount of boost, gave me a bit of a fright

I thought I ask before I start disassembling parts of the bike..

Something wrong, or is it a property of this turbo?

Thanks

-

1

1

-

-

On 2/26/2024 at 7:46 PM, johnr said:

Is it that o ring that's leaking? Plenty of oil leaks on heads are due to the o rings on the centre cylinders head nuts.

O-rings on centrel cylinder head nuts?

The outer nuts have copper washers, but I never have seen O-rings on other nuts..

-

For making the holes in the crankcase bigger, I did it like this with my GS1000;

Make yourself a disc, 1 side the diameter of the new barrel, the other side the diameter of the headgasket.

Put the dowel pins in the crankcase, put the headgasket with the disc in it over the dowel pins, push disc down and draw a line around it.

Now take material way with a barrel grinder, finish it with those wheels with emery.

Takes about 45 minutes per hole/barrel.

For making the base gasket bigger, also do this with a/the disc

-

1

1

-

-

On 3/1/2024 at 6:12 AM, Duckndive said:

Yeap your 1st challenge will be getting the studs out

2 nuts at the top, tighten them properly, and turn them out with the lower nut, put a ring spanner over the stud first.

-

Can't you make the clutch control hydraulic?

-

-

Hydraulic clutch

-

On 2/21/2024 at 10:47 PM, PaintItBlack said:

Thank you,

and could you confirm that you are using the cometic fibre gasket,

were you advised that the O ring wasn’t required, or did you just figure that the head gasket and a dab of liquid gasket would do the job,

thanks

I have a fibre cometic gasket.

It's just a chain tunnel, no pressure on the oil, just a lot of splatter.

Oil is mostly on the front and back, never had problems at the back.

The headgasket is a gasket, so why would it create problems?

I didn't put an O-ring in because I didn't had one.

The teardrop ones at the bottom can be reused too, but do measure the thickness!! If the thickness is still the same you could do it, if they're thinner, replace them.

Also feel if they're still soft, if they're hardened replace them!

-

1

1

-

-

15 hours ago, PaintItBlack said:

got to whip the head off my 1085BB GS1000, have recently heard the O ring isn’t required with the cometic fibre head gasket, is that correct,

and could the fact that I fitted an O ring last time I had it apart be the reason why the head gasket never really sealed, and got progressively worse ,

pain in the arse as runs really well, but covers the engine and my jeans in oil every time I ride it

I haven't put the O-ring on mine.

Do put some liquid gasket on the front, and a bit to the sides, of the chain tunnel

-

Update;

Got the bike going again after the accident, had to butcher another frame..

The plenum (160cc bigger) I have made defenitly a difference! Better throttle response off boost, on boost I can't really tell because I also put another turbo on it.

But I needed bigger jets.

It's a bit stronger in the lower revs, and a better throttle response, so it wasn't a waste of time

-

3

3

-

-

On 1/31/2024 at 4:27 AM, gsx said:

If that's welded properly it shouldn't be a problem

-

1

1

-

-

-

8 hours ago, coombehouse said:

I stopped doing that a few years ago when I tasted a mystery liquid near the front wheel of my bike. It was cat piss

At least the mystery was solved

-

1

1

-

-

21 hours ago, clivegto said:

No even though it's a bigger turbo it spines up quicker. They have ceramic ball bearings enabling them to spin up faster 500 to 1000 rpm I would say.

Thanks.

I thought it would spool up about the same..

I'll have some investigation to do then.

-

On 1/21/2019 at 1:33 AM, clivegto said:

Why do you say that Rob ?

Bought a rebuilt one (IHI VF23) today with p20 exhaust housing but a slightly bigger compressor wheel giving it 20 to 30% more power, new ceramic bearings & new wheels. Hopefully it will be good.

I've ot the VF23 on my bike now, had a TD04 before.

Haven't riden it a lot, have to instal the bleedvalve aain. I thought the VF23 made about 19/20 psi standard, but mine only made 10.

Does your VF23 also spools up quite a bit slower then the TD04?

-

20 hours ago, keith said:

you can get imd pistons and rings for about 300 quid they are made in england

That's not cheap!

Iirc I paid 250AUD the last time I ordered a set.

turbo pistons

in Forced Induction

Posted · Edited by Reinhoud

Again,; I'm not an expert, I just wrote what my experience is. But when you have a carburated engine you can also have a richer mixture..

How many EFI's run perfect? How many bikes have knock sensors?

I've seen quite a few dyno graphs with a crappy AFR line, while a carburated AFR line is almost perfect..

In theorie a EFI can be/should better then a caruretor, in reality, how many really are?